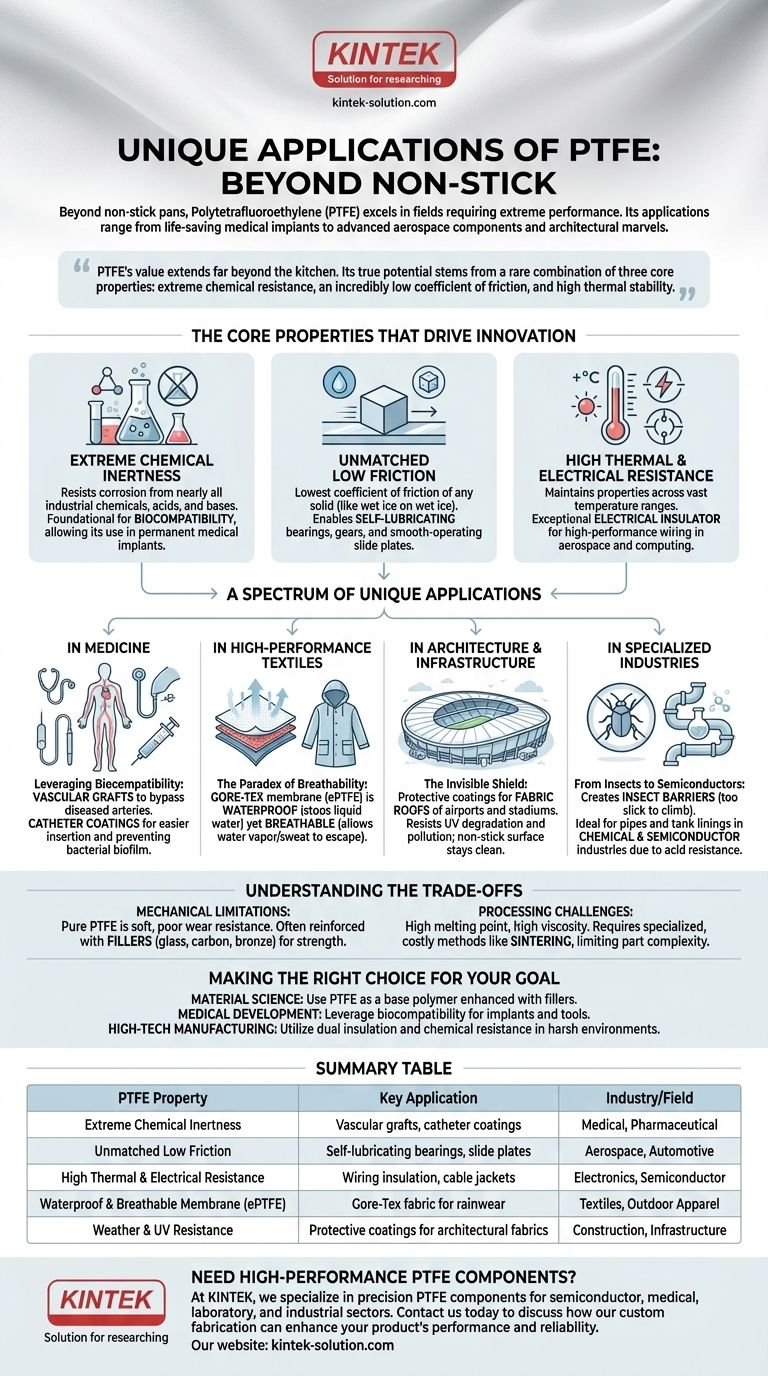

Beyond non-stick pans, the unique applications of Polytetrafluoroethylene (PTFE) are found in fields requiring extreme performance, including medicine, aerospace, and architecture. It is used as a biocompatible graft material in surgery, a protective coating on catheters to prevent bacterial growth, and as the breathable yet waterproof membrane in high-performance rainwear like Gore-Tex.

PTFE's value extends far beyond the kitchen. Its true potential is unlocked by understanding that its diverse applications all stem from a rare combination of three core properties: extreme chemical resistance, an incredibly low coefficient of friction, and high thermal stability.

The Core Properties That Drive Innovation

To grasp PTFE's versatility, you must first understand the fundamental characteristics that make it unlike most other polymers. These properties are not just features; they are the reasons it is specified for mission-critical tasks.

Extreme Chemical Inertness

PTFE is one of the most non-reactive substances known to science. It resists corrosion and degradation from nearly all industrial chemicals, acids, and bases.

This inertness is why the human body does not reject it, making it highly biocompatible. This property is the foundation for its use in permanent medical implants.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a quality often compared to wet ice on wet ice. This means materials slide over its surface with almost no resistance.

This "non-stick" nature is useful for more than just cookware. It enables the creation of self-lubricating bearings, gears, and slide plates that operate smoothly without external lubricants.

High Thermal and Electrical Resistance

This material maintains its properties across a vast temperature range and is an exceptional electrical insulator.

This combination makes it indispensable for high-performance wiring and cable insulation, especially in demanding environments like aerospace and computing where signal integrity and fire resistance are critical.

A Spectrum of Unique Applications

These core properties translate directly into tangible, and often surprising, real-world applications across various industries.

In Medicine: Leveraging Biocompatibility

The body's acceptance of PTFE allows it to be used for life-saving devices. It is formed into vascular grafts that replace or bypass diseased arteries.

Its low-friction surface is also applied as a coating on medical instruments like catheters, which makes them easier to insert and helps inhibit the formation of bacterial biofilms.

In High-Performance Textiles: The Paradox of Breathability

The well-known Gore-Tex brand is built on a thin, microporous membrane of expanded PTFE (ePTFE).

The pores in this membrane are too small for liquid water droplets to pass through but large enough for water vapor (sweat) to escape, creating a fabric that is both waterproof and breathable.

In Architecture and Infrastructure: The Invisible Shield

Due to its weather resistance and durability, PTFE is used as a protective coating for the fabric roofs of large structures like airports and stadiums.

This coating protects the underlying material from UV degradation and environmental pollutants, extending the structure's lifespan while its non-stick surface helps keep it clean.

In Specialized Industries: From Insects to Semiconductors

In a simple but clever application, a band of PTFE painted on the inner walls of an enclosure creates a surface so slick that insects cannot climb it.

In high-tech fields, its resistance to aggressive acids makes it the ideal material for pipes, valves, and tank linings in the chemical and semiconductor industries.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively and avoiding misapplication.

Mechanical Limitations

Pure PTFE is a relatively soft material with poor resistance to wear and creep (the tendency to slowly deform under load).

For mechanical applications like bearings or seals, it is often reinforced with fillers like glass fiber, carbon, or bronze to improve its strength and durability.

Processing Challenges

PTFE has a very high melting point and viscosity, which means it cannot be processed using conventional melt-extrusion or molding techniques common to other plastics.

It requires specialized, and often more costly, methods like compression molding and sintering, which can limit the complexity of parts that can be manufactured.

Making the Right Choice for Your Goal

Understanding PTFE's core strengths and weaknesses allows you to identify where it can provide a decisive advantage.

- If your primary focus is material science or engineering: Recognize that PTFE's properties, particularly its low friction and inertness, make it an exceptional base polymer that can be enhanced with fillers for demanding mechanical roles.

- If your primary focus is medical device development: Leverage its unmatched biocompatibility and low friction as the foundation for creating safer, more effective implants, grafts, and surgical tools.

- If your primary focus is high-tech manufacturing: Utilize its dual capabilities as a superior electrical insulator and a chemically impervious material for components that must perform in the harshest environments.

Ultimately, appreciating PTFE is about looking past the frying pan and seeing a high-performance material defined by its ability to solve problems that other materials simply cannot.

Summary Table:

| PTFE Property | Key Application | Industry/Field |

|---|---|---|

| Extreme Chemical Inertness | Vascular grafts, catheter coatings | Medical, Pharmaceutical |

| Unmatched Low Friction | Self-lubricating bearings, slide plates | Aerospace, Automotive |

| High Thermal & Electrical Resistance | Wiring insulation, cable jackets | Electronics, Semiconductor |

| Waterproof & Breathable Membrane (ePTFE) | Gore-Tex fabric for rainwear | Textiles, Outdoor Apparel |

| Weather & UV Resistance | Protective coatings for architectural fabrics | Construction, Infrastructure |

Need High-Performance PTFE Components?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in custom fabrication ensures your parts meet the strictest demands for chemical resistance, low friction, and thermal stability.

Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications