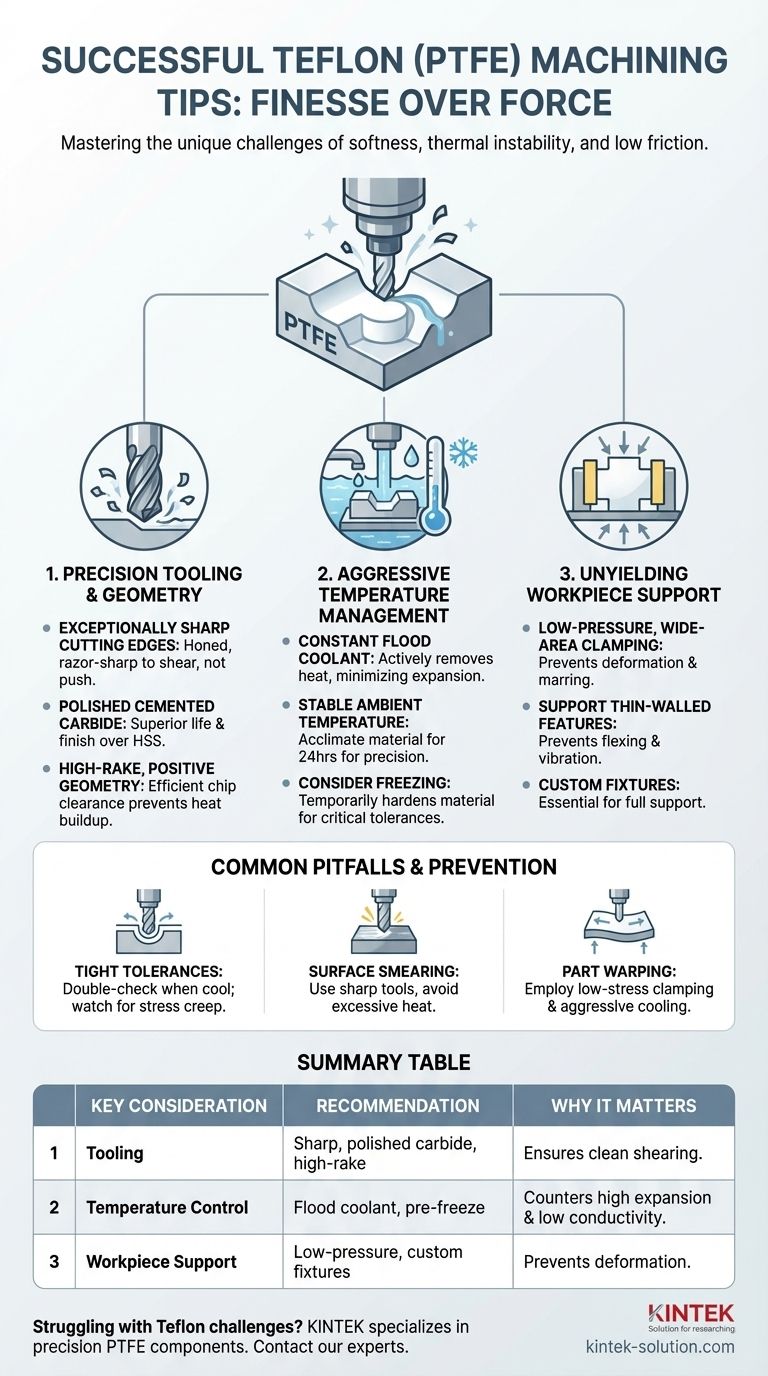

To machine Teflon (PTFE) successfully, you must focus on three critical areas: using exceptionally sharp, polished carbide tools with geometries that promote chip clearance, aggressively managing temperature with coolants or even by freezing the material, and providing robust workpiece support to prevent the soft material from deforming under pressure. These techniques directly counteract Teflon's inherent softness, low thermal conductivity, and high rate of thermal expansion.

The core challenge of machining Teflon is not its hardness, but its unique combination of softness, thermal instability, and low friction. Success requires a strategy of finesse over force, focusing entirely on managing heat buildup and preventing physical deformation at every stage of the process.

Why Machining Teflon Is a Unique Challenge

Before applying specific techniques, it's essential to understand the material properties that dictate the entire machining strategy. Teflon's most valuable characteristics for its final application are the very things that make it difficult to process accurately.

The Problem of Softness

Teflon is an exceptionally soft material. This means it has a strong tendency to compress, deform, or smear under tool pressure rather than cutting cleanly.

This requires extremely sharp cutting edges and a workholding strategy that supports the entire part, preventing it from flexing away from the tool.

The Problem of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even a small increase in temperature from cutting friction will cause the material to expand significantly.

This expansion can ruin dimensional accuracy, making it impossible to hold tight tolerances if heat is not actively managed. It is the primary reason coolant is not just recommended, but essential.

The Problem of Low Thermal Conductivity

Compounding the expansion issue, Teflon is an excellent insulator. It does not dissipate heat well.

This means that any heat generated by the cutting tool stays concentrated at the cutting point, quickly leading to material expansion, gumming, and potential melting.

The Pillars of Successful Teflon Machining

A successful approach is built on controlling the factors of tooling, temperature, and support. Getting any one of these wrong will compromise the final part.

Tool Selection and Geometry

The right tool is the most important factor in achieving a clean cut instead of a smeared mess.

Use extremely sharp cutting edges. A honed, razor-sharp edge is mandatory. Any dullness will cause the tool to push and smear the material rather than shear it.

Choose cemented carbide tools. While sharp high-speed steel (HSS) can work, polished cemented carbide tools provide superior life and surface finish.

Ensure a high-rake, positive geometry. The tool must be designed to lift and evacuate chips away from the workpiece efficiently. Poor chip clearance leads to heat buildup and surface damage.

Aggressive Temperature Management

Controlling the part's temperature is controlling its dimensions. This cannot be overstated.

Apply a constant flood of coolant. Water-soluble coolants are excellent for actively removing heat from the cutting zone, minimizing thermal expansion.

Maintain a stable ambient temperature. For high-precision jobs, allow the material to acclimate to the shop's temperature for 24 hours before machining to ensure a stable starting point.

Consider freezing the material. For the most critical tolerances, temporarily freezing the PTFE makes it harder and more rigid. This drastically reduces deformation and thermal effects, allowing for more precise cuts.

Unyielding Workpiece Support

Because Teflon is so soft, it will easily deform under clamping pressure or the force of the cut itself.

Use low clamping pressure across a wide surface area. Avoid sharp-jawed vises that can mar or indent the material. Custom soft jaws or fixtures that fully support the part are ideal.

Support thin-walled or delicate features. Ensure the material directly behind the area being cut is fully supported to prevent it from flexing or vibrating.

Understanding the Common Pitfalls

Even with the right strategy, certain challenges are inherent to working with PTFE. Recognizing them is key to troubleshooting and prevention.

The Challenge of Tight Tolerances

Holding tight tolerances is difficult due to the combined effects of thermal expansion and stress creep—the tendency of the material to slowly deform over time when under pressure.

Always double-check dimensions after the part has cooled to room temperature, and be aware that post-machining movement can occur.

Avoiding Surface Smearing and Burrs

Smearing is a sign that the material is melting or being pushed by the tool instead of being cut. It is almost always caused by a dull tool, excessive heat, or incorrect feed rates.

Likewise, Teflon does not produce a conventional "chip" but rather a continuous, gummy swarf. Sharp tools and proper geometry are essential to shear this material cleanly and prevent large burrs.

Mitigating Part Warping

Warping can occur both during and after machining. It's typically caused by internal stresses in the material being released or by excessive heat and clamping force.

Using low-stress clamping methods and aggressive cooling is the best way to prevent the part from changing shape unexpectedly.

Making the Right Choice for Your Goal

Your machining strategy should adapt to the specific requirements of the finished part.

- If your primary focus is achieving the tightest tolerances: Prioritize aggressive temperature control, including pre-chilling or freezing the material before making final passes.

- If your primary focus is the best possible surface finish: Concentrate on using exceptionally sharp, polished carbide tools and consider post-machining bead blasting for a uniform matte finish.

- If your primary focus is preventing deformation on thin-walled parts: Design fixtures that provide complete support to the workpiece and use a constant flood of coolant to prevent heat-induced warping.

Ultimately, mastering Teflon machining comes from respecting the material's unique properties and adapting your process to accommodate them.

Summary Table:

| Key Consideration | Recommendation | Why It Matters |

|---|---|---|

| Tooling | Use sharp, polished carbide tools with high-rake geometry. | Ensures clean shearing instead of smearing the soft material. |

| Temperature Control | Apply flood coolant or pre-freeze the material. | Counters high thermal expansion and low conductivity to hold tolerances. |

| Workpiece Support | Use low-pressure, wide-area clamping and custom fixtures. | Prevents deformation of the soft PTFE under cutting or clamping forces. |

Struggling with Teflon machining challenges like smearing, warping, or holding tight tolerances? You don't have to. At KINTEK, we specialize in the precision manufacturing of PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, and industrial sectors. Our expertise in advanced tooling and temperature management ensures your PTFE parts are machined to exact specifications, every time.

Let us handle the complexities. Contact our experts today to discuss your project, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key properties that make Teflon plastic sheets suitable for industrial applications? Unlock Unmatched Performance

- What are the different types of PTFE rods available based on manufacturing technology? Choose the Right Type for Your Project

- What are the advantages of using PTFE Lip Seals in high-speed rotary applications? Achieve Superior Speed and Reliability

- In which industries are PTFE bellow mechanical seals commonly used? The Ultimate Solution for Corrosive Fluids

- What maintenance practices ensure optimal PTFE butterfly valve performance? Maximize Lifespan & Reliability

- What are the characteristics of glass-filled PTFE gaskets? Boost Strength & Stability for Demanding Seals

- Why are ePTFE gaskets suitable for food and pharmaceutical industries? Ensure Product Purity and Compliance

- What secondary manufacturing processes might PTFE parts require? Achieve Precise Specifications with Expert Machining