In short, PTFE valve seat rings are high-performance sealing components used inside industrial valves to create a leak-proof shutoff. They are essential in applications where the process fluid is chemically aggressive, requires high purity, or where low-friction operation is critical for the valve's performance and longevity.

The core value of a PTFE valve seat is not just its ability to seal, but its capacity to maintain that seal under conditions—extreme chemical exposure, temperature fluctuations, and constant friction—that would cause most other materials to fail.

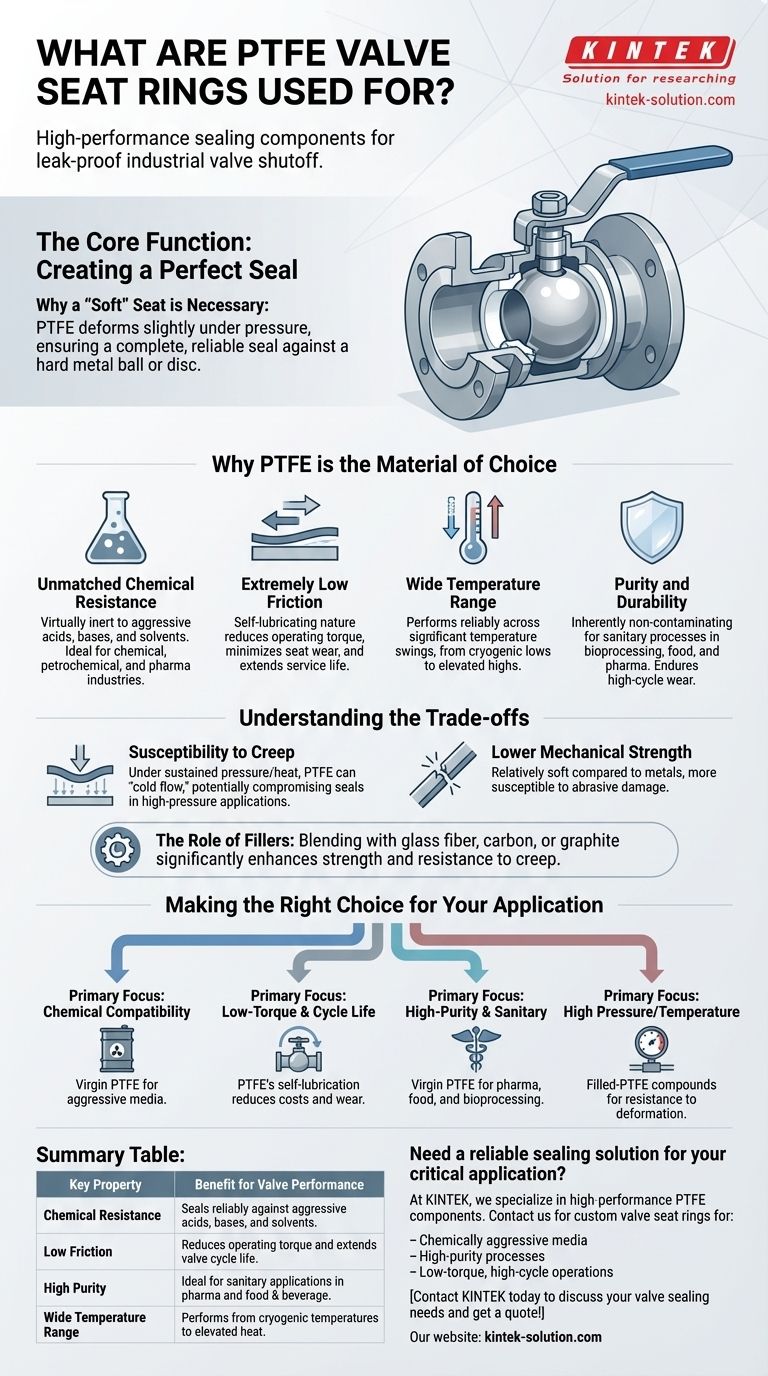

The Core Function: Creating a Perfect Seal

A valve's primary job is to start, stop, or regulate flow. The quality of its shutoff capability depends almost entirely on the integrity of its seat.

Why a "Soft" Seat is Necessary

Most industrial valves, like ball or butterfly valves, use a hard metal component (a ball or disc) to block the flow. To achieve a bubble-tight seal, this metal component must press against a softer, more conforming material.

This is the role of the valve seat ring. PTFE, a resilient polymer, deforms slightly under pressure to fill any microscopic imperfections between the ball or disc and the valve body, ensuring a complete and reliable seal.

Why PTFE is the Material of Choice

While other polymers can be used for valve seats, PTFE (Polytetrafluoroethylene) possesses a unique combination of properties that make it the superior choice for demanding applications.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and bases. This makes it the default choice for valves used in the chemical, petrochemical, and pharmaceutical industries, where aggressive media would quickly degrade lesser materials.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a property often compared to wet ice on wet ice. This self-lubricating nature means less torque is required to open or close the valve, reducing the size and cost of the actuator needed. It also minimizes wear on the seat, extending the valve's service life.

Wide Temperature Range

PTFE components perform reliably across a vast temperature spectrum, from cryogenic lows to elevated highs. This makes them suitable for processes that experience significant temperature swings.

Purity and Durability

In industries like bioprocessing, food and beverage, and pharmaceuticals, process purity is paramount. Virgin PTFE is inherently non-contaminating. It also endures significant wear and tear, providing a long-lasting seal even under high-cycle conditions.

Understanding the Trade-offs

No material is perfect. To make an informed decision, it is critical to understand the limitations of standard PTFE.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can be prone to "creep" or "cold flow," where the material slowly deforms over time. This can eventually compromise the integrity of the seal in high-pressure applications.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. It can be more susceptible to damage from abrasive media or improper installation.

The Role of Fillers

To mitigate these limitations, PTFE is often blended with fillers like glass fiber, carbon, or graphite. These filled-PTFE compounds significantly enhance the material's mechanical strength and resistance to creep, making them suitable for more demanding service conditions while retaining most of the base material's benefits.

Making the Right Choice for Your Application

Selecting the correct seat material is crucial for valve performance and safety. Your decision should be guided by your primary operational goal.

- If your primary focus is chemical compatibility: Virgin PTFE is the industry standard for handling aggressive media where other elastomers or plastics would fail.

- If your primary focus is low-torque operation and cycle life: PTFE's self-lubricating properties reduce actuation costs and minimize seat wear over thousands of cycles.

- If your primary focus is high-purity or sanitary processes: The inert nature of virgin PTFE makes it ideal for applications in the pharmaceutical, food, and bioprocessing industries.

- If you are dealing with high pressure or temperature: You should strongly consider a filled-PTFE compound to gain the necessary resistance to deformation and creep.

Ultimately, selecting a PTFE valve seat is a decision for unparalleled sealing reliability in the most demanding service conditions.

Summary Table:

| Key Property | Benefit for Valve Performance |

|---|---|

| Chemical Resistance | Seals reliably against aggressive acids, bases, and solvents. |

| Low Friction | Reduces operating torque and extends valve cycle life. |

| High Purity | Ideal for sanitary applications in pharma and food & beverage. |

| Wide Temperature Range | Performs from cryogenic temperatures to elevated heat. |

Need a reliable sealing solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom valve seat rings. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production ensures a perfect seal for:

- Chemically aggressive media

- High-purity processes

- Low-torque, high-cycle operations

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your valve sealing needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are common applications of machined Teflon/PTFE parts? Solve Extreme Engineering Challenges

- What are the common CNC machining methods for Teflon parts? Mastering PTFE's Unique Challenges

- What makes PTFE versatile in medical applications? Unlock the Power of Biocompatible Polymers

- What temperature range can PTFE oil seals withstand? From -200°C to +260°C for Extreme Applications

- What industries benefit from the high-temperature and high-pressure resistance of PTFE bellows? Ensure System Integrity in Demanding Applications

- What is the recommended method for cleaning Teflon PTFE sheets? A Guide to Preserving Non-Stick Performance

- In which industries are spring-energized PTFE seals commonly used? Critical Applications for Extreme Conditions

- What are the key takeaways when comparing FR4 and PTFE laminates? Choosing the Right PCB Material for Your Application