In professional and industrial contexts, PTFE seals are most commonly known by the prominent brand name Teflon® seals. Although Teflon is a specific trademark for polytetrafluoroethylene (PTFE), its widespread recognition has made the names nearly interchangeable in conversation and even in some technical documentation.

While the name "Teflon" is a useful shorthand, the real key is understanding the material itself: polytetrafluoroethylene (PTFE). Its unique combination of chemical, thermal, and low-friction properties makes it a critical problem-solver for sealing applications where conventional materials would quickly fail.

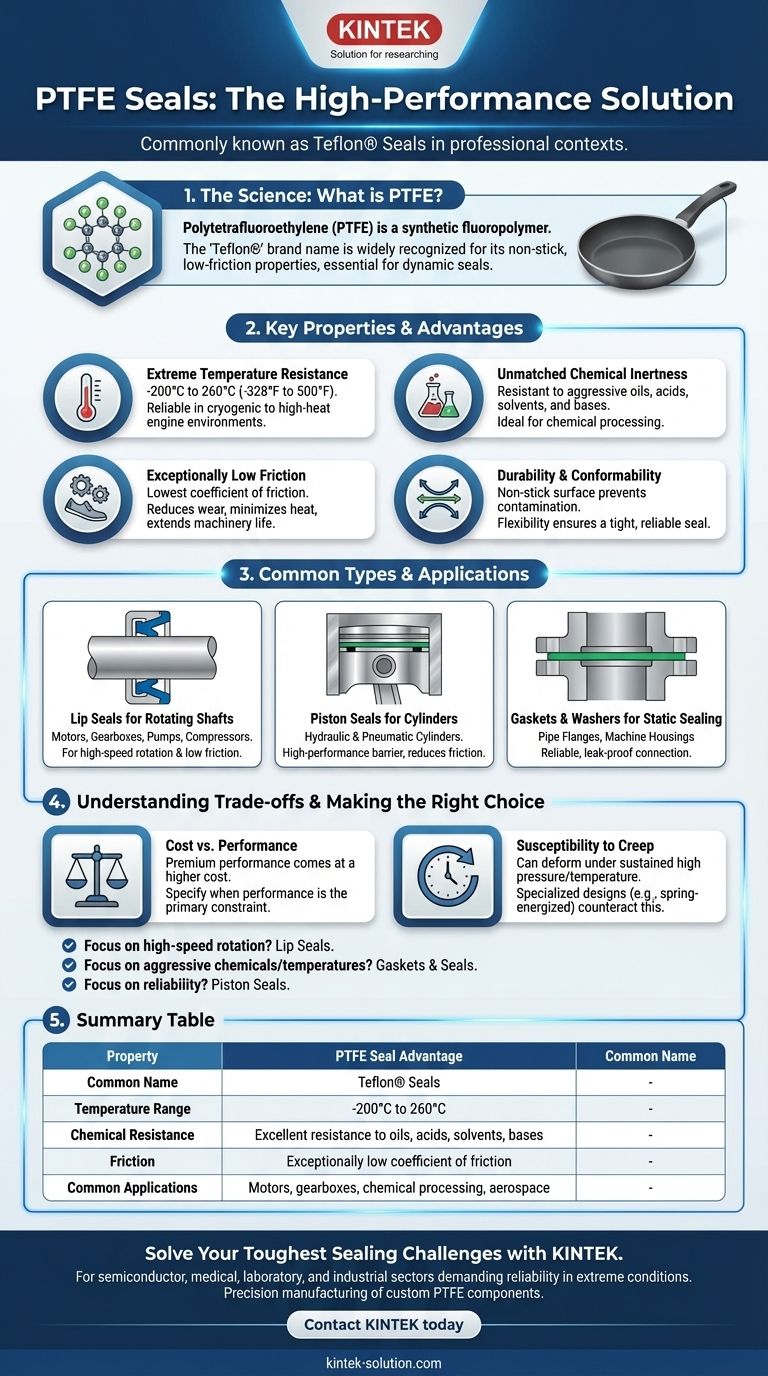

What is PTFE? The Science Behind the Seal

A High-Performance Fluoropolymer

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer. This specific chemical structure is the source of its remarkable and highly desirable characteristics.

The "Teflon" Connection

Most people know PTFE from its use in non-stick cookware under the brand name Teflon. This same non-stick, low-friction property that prevents food from sticking is what makes it an exceptional material for dynamic seals in industrial machinery.

Key Properties That Define PTFE Seals

Extreme Temperature Resistance

PTFE seals perform reliably across an incredibly wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This allows them to function in cryogenic applications as well as high-heat environments like engines and transmissions.

Unmatched Chemical Inertness

The material is exceptionally resistant to a vast array of chemicals, including aggressive oils, acids, solvents, and bases. This makes PTFE seals the default choice in chemical processing, pharmaceutical, and food-grade applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" is critical in rotating applications, as it reduces wear, minimizes heat generation, and extends the service life of both the seal and the machinery.

Durability and Conformability

The material's non-stick properties prevent contaminants from adhering to the seal surface, reducing the risk of abrasive wear. Its flexibility also allows it to conform well to shaft and housing surfaces, ensuring a tight and reliable seal.

Common Types and Their Applications

Lip Seals for Rotating Shafts

Designed for dynamic, rotating applications, PTFE lip seals are essential in motors, gearboxes, pumps, and compressors. They are also heavily used in high-performance automotive systems like turbochargers and transmissions where heat and speed are major factors.

Piston Seals for Cylinders

In hydraulic and pneumatic cylinders, PTFE piston seals provide a high-performance barrier that reduces friction and ensures efficient operation. Their durability far surpasses that of many traditional seal materials in these high-pressure environments.

Gaskets and Washers for Static Sealing

For non-moving applications, PTFE gaskets and washers create a reliable seal between two stationary surfaces, such as pipe flanges or machine housings. Their chemical and temperature resistance ensures a long-lasting, leak-proof connection.

Specialized Seals for Extreme Environments

Variants like spring-energized seals use a metal spring to provide consistent force, making them ideal for high-pressure or cryogenic use cases in aerospace, robotics, and energy sectors.

Understanding the Trade-offs

Cost vs. Performance

PTFE is a premium performance material, and its cost reflects that. For low-temperature, low-speed applications with non-aggressive fluids, a standard elastomer (rubber) seal is often a more economical choice. PTFE is specified when performance, not budget, is the primary constraint.

Susceptibility to Creep

Under high, sustained pressure and temperature, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. This is why specialized designs, such as spring-energized or filled PTFE seals, are engineered to counteract this tendency in demanding applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's properties to the operational demands.

- If your primary focus is high-speed rotation and low friction: PTFE lip seals are the superior choice for minimizing wear and heat in motors, spindles, and transmissions.

- If your primary focus is resisting aggressive chemicals or extreme temperatures: PTFE's inertness makes it the only viable option for gaskets and seals in chemical processing or cryogenic equipment.

- If your primary focus is reliability in hydraulic or pneumatic systems: PTFE piston seals offer a significant upgrade in performance and longevity over standard alternatives.

Ultimately, understanding the fundamental properties of PTFE allows you to solve engineering challenges that are simply beyond the limits of other materials.

Summary Table:

| Property | PTFE Seal Advantage |

|---|---|

| Common Name | Teflon® Seals (Brand Name) |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| Chemical Resistance | Excellent resistance to oils, acids, solvents, and bases |

| Friction | Exceptionally low coefficient of friction |

| Common Applications | Motors, gearboxes, chemical processing, hydraulic cylinders, aerospace |

Solve Your Toughest Sealing Challenges with KINTEK

PTFE seals are critical for applications where performance, not budget, is the primary constraint. If your operations in the semiconductor, medical, laboratory, or industrial sectors demand reliability in extreme temperatures, aggressive chemicals, or high-speed rotation, KINTEK has the solution.

We specialize in the precision manufacturing of custom PTFE components, including seals, liners, and labware. From initial prototypes to high-volume production, our expertise ensures you get a seal engineered for your specific application's demands, maximizing performance and longevity.

Don't let a standard seal limit your equipment's potential. Contact KINTEK today to discuss your custom PTFE sealing needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- How do Teflon bushes perform in chemically harsh environments? Unmatched Chemical Resistance for Critical Applications

- How is the PTFE lining process carried out? A Guide to Flawless Corrosion Protection

- How is PTFE used in football protective gear? Enhancing Performance and Safety

- How are PTFE gaskets applied in the automotive industry? Ensure Reliable Seals in Harsh Environments

- What is the temperature range for PTFE O-rings? Withstand Extremes from -200°C to 260°C

- How can leaking in a PTFE butterfly valve be fixed? A Guide to Reliable Sealing Solutions

- What is a PTFE sliding bearing pad and where is it used? Essential for Structures & Heavy Equipment