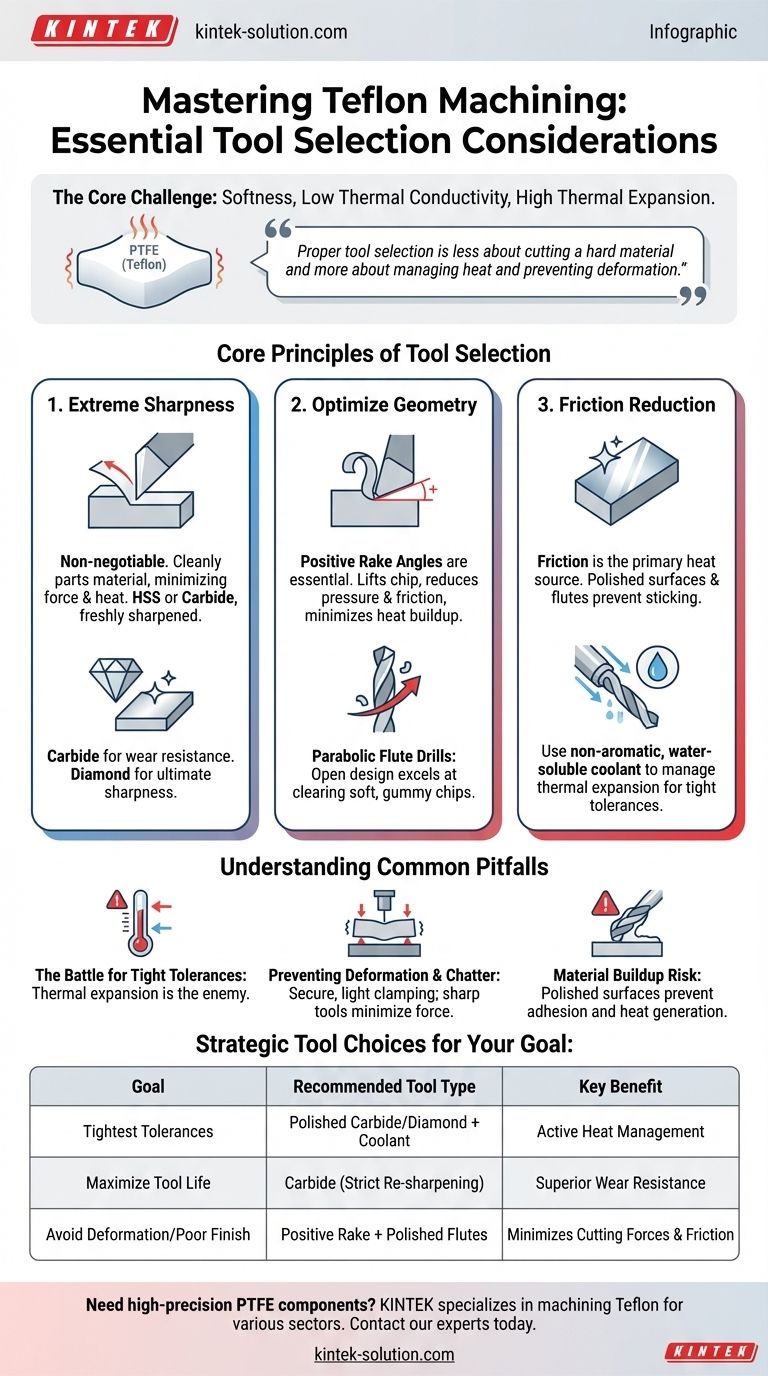

For machining Teflon (PTFE), the most critical considerations are using extremely sharp tools, typically made of high-speed steel or carbide, with a positive rake angle. This specific geometry ensures the tool shears the material cleanly rather than pushing it, which minimizes heat generation, friction, and part deformation—the primary challenges associated with this unique polymer.

The core challenge in machining Teflon is not its hardness, but its softness, low thermal conductivity, and high thermal expansion. Therefore, proper tool selection is less about cutting a hard material and more about managing heat and preventing the soft material from deforming or tearing.

Why Teflon Demands a Specialized Approach

Understanding Teflon's inherent properties is the key to selecting the right tools. Unlike metals, Teflon presents a unique set of behaviors that directly influence the machining process and final part quality.

The Impact of Softness and Low Strength

Teflon's softness makes it easy to cut but also easy to deform. A dull tool or one with the wrong geometry will push and tear the material instead of creating a clean chip, resulting in a poor surface finish and dimensional inaccuracy.

Its low strength compared to other polymers means it offers little resistance, requiring exceptionally sharp and often narrow tools to achieve a precise shearing action.

The Challenge of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even a small amount of heat generated by friction during cutting can cause the material to expand significantly, making it nearly impossible to hold tight tolerances.

The goal of any tooling choice must be to generate the absolute minimum amount of heat.

The Problem of Stress Creep

This material is also prone to "stress creep," meaning it will slowly deform over time when under pressure. Improper clamping or the pressure from a dull cutting tool can introduce stress that leads to dimensional changes long after the machining is complete.

Core Principles of Teflon Tool Selection

Effective tooling counteracts the material challenges above. The right choice is based on a few fundamental principles focused on sharpness, geometry, and friction reduction.

Prioritize Extreme Sharpness

A sharp cutting edge is non-negotiable. It cleanly parts the material at the molecular level, minimizing the force required and thus reducing both heat and induced stress.

Both high-speed steel (HSS) and carbide tools can be used, but they must be maintained in a freshly sharpened condition. For high-volume production, carbide offers superior wear resistance.

Optimize Tool Geometry

The geometry of the cutting tool has a profound impact on performance. Positive rake angles are essential because they help lift the chip up and away from the workpiece.

This action reduces cutting pressure and friction, which in turn minimizes heat buildup and the risk of deforming the part.

Focus on Friction Reduction

Friction is the primary source of heat in Teflon machining. Using tools with highly polished surfaces or flutes significantly reduces the coefficient of friction, preventing material from sticking to the tool and further reducing heat.

Specialized options like diamond cutters offer the ultimate in sharpness and low friction, providing superior performance where budget allows.

Use Specialized Tooling for Specific Operations

Standard tools are often insufficient. For drilling, parabolic flute drills are recommended because their open design excels at clearing the soft, gummy chips, preventing them from packing in the hole and generating excess heat.

Understanding the Common Pitfalls

Even with the right tool material, overlooking key operational factors can lead to failure. The tool is only one part of a complete system.

The Battle for Tight Tolerances

Achieving tight tolerances is the primary battle. A slightly dull tool generates heat, the part expands, you machine it to size, and then it cools and shrinks, falling out of tolerance. Using a non-aromatic, water-soluble coolant is often recommended to manage this thermal expansion and improve tool life.

Preventing Deformation and Chatter

The softness of Teflon makes it susceptible to chatter (vibration) and deformation. The workpiece must be clamped securely but without excessive force that could crush it. A sharp tool with the correct geometry minimizes cutting forces, which is the best defense against both chatter and deformation.

The Risk of Material Buildup

Teflon's softness can cause it to adhere to the cutting tool, especially if the tool surface is not smooth. This buildup increases friction, generates more heat, and degrades the surface finish. Polished tools are essential to prevent this.

Making the Right Choice for Your Goal

Your specific objective should guide your final tool selection and process parameters.

- If your primary focus is achieving the tightest possible tolerances: Opt for extremely sharp, polished carbide or diamond tools combined with a water-soluble coolant to actively manage thermal expansion.

- If your primary focus is maximizing tool life in a production environment: Use carbide tools for their superior wear resistance, but implement a strict regimen for re-sharpening to maintain a keen edge.

- If your primary focus is avoiding part deformation and poor surface finish: Prioritize tools with high positive rake angles and polished flutes, and ensure your workpiece is securely fixtured to prevent any vibration.

Ultimately, treating Teflon with the right tooling transforms a challenging material into one that can be machined with precision and predictability.

Summary Table:

| Consideration | Key Factor | Recommended Tool Type |

|---|---|---|

| Sharpness | Minimizes heat and stress | High-Speed Steel (HSS), Carbide, Diamond |

| Geometry | Shears material cleanly | Positive Rake Angle |

| Friction | Reduces heat buildup | Polished Flutes, Parabolic Flute Drills |

Need high-precision PTFE components? KINTEK specializes in machining Teflon for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in tool selection and custom fabrication—from prototypes to high-volume orders—ensures your parts meet the tightest tolerances without deformation. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary advantages of expanded PTFE? Achieve Superior Sealing and Performance

- What are machined PTFE parts made of? The Power of Pure Carbon and Fluorine

- What are the three primary classifications of PTFE gasket materials? Skived, Structured, or Expanded PTFE

- What additional services are offered with PTFE expansion joints? Ensure a Perfect Fit for Your System

- What are some examples of filled PTFE seals and their properties? Enhance Performance for Demanding Applications

- What are the main differences between NBR and PTFE seats in butterfly valves? Select the Right Seal for Your System

- What are the advantages of using PTFE combined with glass fiber aggregates? Achieve Superior Strength & Durability

- Why are PTFE reducing flanges considered cost-effective? Maximize Uptime and Minimize Costs