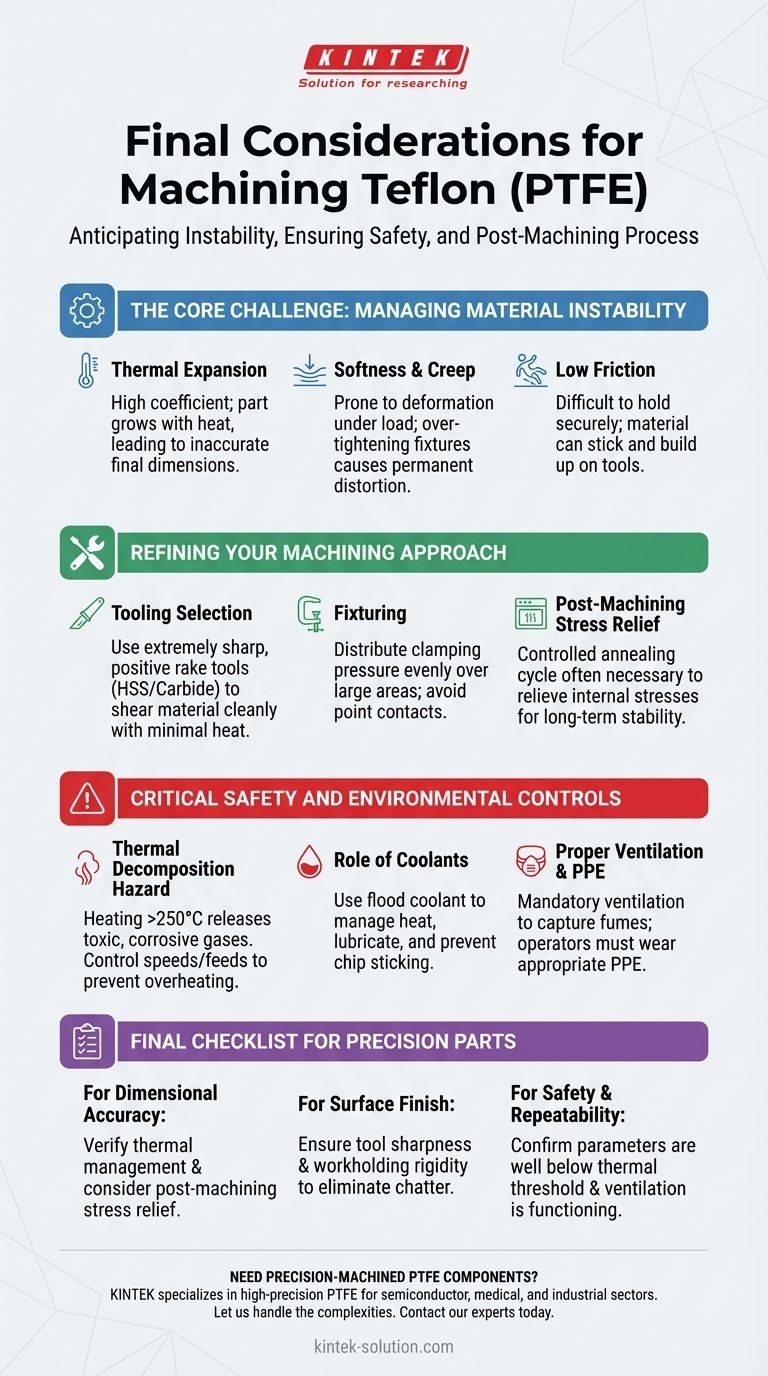

The most important final considerations when machining Teflon (PTFE) are anticipating the material's instability, implementing stringent safety protocols, and often performing a post-machining stress relief process. Success with Teflon is less about the cutting itself and more about controlling the thermal and physical forces that cause it to deform, creep, and release hazardous fumes.

Teflon's defining characteristics—its softness, high thermal expansion, and low friction—are also its greatest machining challenges. Mastering this material requires a strategy focused on minimizing heat, securing the workpiece without distortion, and prioritizing operator safety above all else.

The Core Challenge: Managing Material Instability

Machining Teflon is fundamentally different from machining metals or even other plastics. The material's unique properties require a shift in mindset from aggressive material removal to gentle, precise shaping while managing its inherent instability.

The Problem of Thermal Expansion

Teflon has an extremely high coefficient of thermal expansion. This means it expands and contracts significantly with even minor temperature changes.

Heat generated from the cutting process can cause the part to grow, leading to inaccurate final dimensions once it cools to ambient temperature. This is a primary cause of failing to hold tight tolerances.

Softness, Creep, and Deformation

Teflon is exceptionally soft and prone to stress creep, meaning it will slowly deform over time when under a constant load.

Over-tightening a vise or clamp will not only mar the surface but can permanently distort the part. This softness also makes it susceptible to tool chatter, which degrades surface finish.

The Paradox of Low Friction

The material's famous slipperiness makes it difficult to hold securely for machining. This low coefficient of friction can also cause the material to stick to and build up on the cutting tool, especially if the tool is not sharp enough.

Refining Your Machining Approach

To counteract Teflon's inherent challenges, your final strategy must focus on specialized tooling, careful workholding, and post-machining treatments.

Tooling Selection is Non-Negotiable

Your choice of cutting tool is critical. The goal is to shear the material cleanly with minimal friction and heat generation.

Always use extremely sharp cutting edges. Both high-speed steel (HSS) and carbide tools can work, but sharpness is more important than material. Tools should have a positive rake angle to create a slicing action.

For specific operations like drilling, consider specialized tools like parabolic flute drills that are designed for efficient chip evacuation in soft materials.

The Importance of Fixturing

Securing the workpiece requires a delicate balance. You must hold it firmly enough to resist cutting forces but gently enough to avoid distortion.

Use fixtures with a large surface area to distribute clamping pressure evenly. Avoid point contacts that can dig into and deform the material.

Post-Machining Stress Relief

Even with perfect technique, machining introduces internal stresses into a Teflon part. For applications requiring tight tolerances and long-term stability, a post-machining annealing or stress-relief cycle is often necessary.

This involves heating the part in a controlled oven to a specific temperature below its melting point and then slowly cooling it, allowing the material's internal structure to relax into a stable state.

Critical Safety and Environmental Controls

Failing to manage the machining environment for Teflon is not just a quality issue; it is a serious safety hazard.

The Thermal Decomposition Hazard

Heating Teflon above 250°C (482°F) can cause it to decompose, releasing highly toxic and corrosive gases. These fumes pose a significant health risk.

It is absolutely essential to control cutting speeds and feeds to prevent overheating. Never allow chips to discolor from heat.

The Role of Coolants

Using a flood coolant system is an effective way to manage heat, lubricate the cut, and prevent chips from sticking to the tool.

If machining dry, you must use even more conservative cutting parameters and have a system for efficient chip removal to prevent heat buildup.

Proper Ventilation and PPE

A robust ventilation system is mandatory to capture any potential fumes at the source. Operators should always wear appropriate personal protective equipment (PPE), including safety glasses.

Final Checklist for Precision Teflon Parts

To ensure your process yields a successful outcome, tailor your final review to your primary objective.

- If your primary focus is dimensional accuracy: Your final check must be on thermal management, ensuring your coolant is effective and considering a post-machining stress relief cycle.

- If your primary focus is surface finish: Your final check must be on the sharpness of your cutting tools and the rigidity of your workholding to eliminate chatter.

- If your primary focus is safety and repeatability: Your final check must be to verify that cutting parameters are well below the thermal decomposition threshold and that all ventilation systems are functioning perfectly.

Ultimately, successful Teflon machining comes from respecting the material's properties rather than fighting them.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Thermal Expansion | Prevents dimensional inaccuracy as the part cools. |

| Sharp Tooling | Ensures a clean cut, minimizes heat, and prevents material buildup. |

| Gentle Fixturing | Avoids permanent part deformation from clamping pressure. |

| Safety Protocols | Mitigates risk from toxic fumes released if material overheats (>250°C/482°F). |

| Post-Machining Stress Relief | Relieves internal stresses for long-term dimensional stability. |

Need Precision-Machined PTFE Components?

Machining Teflon to exact specifications requires expertise and specialized processes. KINTEK manufactures high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and manage the critical considerations of thermal expansion, stress relief, and safety for you, from prototypes to high-volume orders.

Let us handle the complexities. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers