To successfully drill PTFE, you must address its unique combination of softness, a low melting point, and high thermal expansion. This requires using extremely sharp, high-speed steel (HSS) drills at moderate speeds to prevent overheating and material deformation. Proper clamping pressure and ensuring the drill is perfectly perpendicular are also critical to avoid dimensional inaccuracies and drill "drifting."

The primary challenge in drilling Polytetrafluoroethylene (PTFE) isn't cutting the material, but controlling it. Its softness and high thermal expansion mean that improper tools, speeds, or clamping pressure will easily deform the part, leading to inaccurate holes.

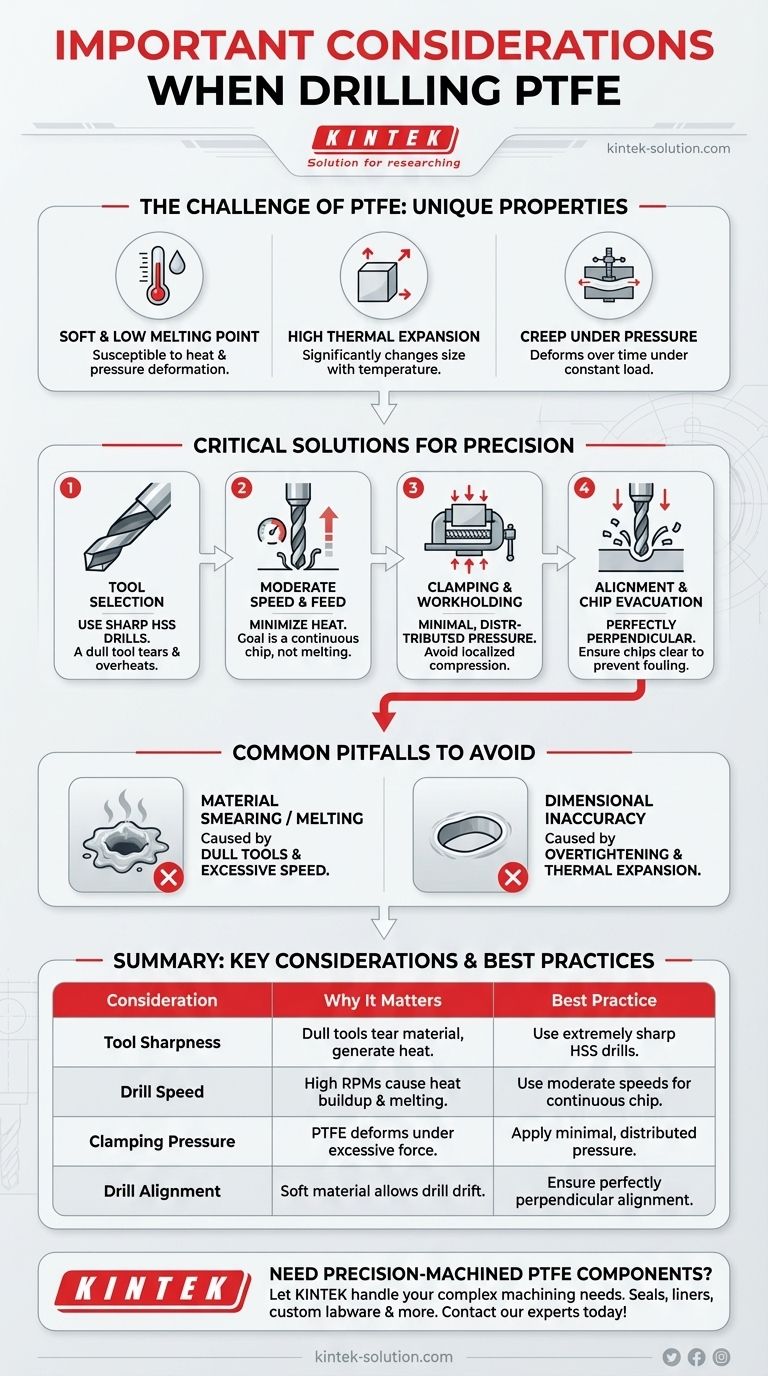

Why Drilling PTFE is a Unique Challenge

To machine any material effectively, you must first understand its nature. PTFE's defining characteristics—while beneficial in its final application—present distinct challenges during fabrication.

Understanding the Core Material Properties

PTFE is famously soft, slippery, and chemically inert. It also has an extremely high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes.

This combination means the material offers little resistance to a cutting tool but is highly susceptible to deformation from both mechanical pressure and heat.

The Risk of Heat Generation

The friction from a drill bit generates heat. Due to PTFE's low melting point and poor thermal conductivity, this heat concentrates at the cutting point instead of dissipating through the material.

Even a small temperature increase will cause the material to expand, making the hole you are drilling smaller than the drill bit. Continued heat will cause it to melt and "smear" rather than cut cleanly.

Deformation Under Pressure

PTFE's softness and tendency to "creep" (deform over time under a constant load) make workholding difficult.

If you clamp a piece of PTFE too tightly in a vise, you will compress it. After you drill a hole and release the pressure, the material will relax, and the hole's dimensions will no longer be accurate.

The Right Tools and Techniques for Precision

Achieving an accurate hole in PTFE is entirely dependent on using the correct tools and a disciplined process that minimizes heat and pressure.

Drill Selection and Geometry

The single most important factor is the tool. Use high-speed steel (HSS) drills that are extremely sharp. A polished, sharp cutting edge will slice through the material cleanly.

A dull drill will push and tear the material, generating excessive friction and heat, which is the primary cause of failure.

Moderate Speeds and Feeds

Resist the temptation to use high RPMs. Moderate cutting speeds are essential to minimize heat generation.

The goal is to create a continuous chip, which indicates the material is being sheared away properly. If the material becomes gummy or melts onto the drill, your speed is too high.

Clamping and Workholding

Secure the workpiece with just enough force to hold it steady. The clamping pressure should be distributed over a large area if possible to avoid localized compression points.

Never overtighten a fixture, as this will guarantee dimensional inaccuracy once the part is released.

Alignment and Chip Evacuation

The drill must be perfectly perpendicular to the workpiece. PTFE's softness allows a drill to easily wander or "drift" off-center if not properly aligned.

Ensure chips are evacuated from the hole as you drill. A buildup of chips can melt and foul the hole, ruining the surface finish and dimensions.

Understanding the Trade-offs and Common Pitfalls

Designing and machining with PTFE requires accepting its inherent limitations. Understanding these trade-offs is key to a successful outcome.

The Challenge of Tight Tolerances

PTFE's high thermal expansion and tendency to creep make it a poor choice for applications requiring extremely tight dimensional tolerances.

A part measured at one temperature will have different dimensions at another. This must be accounted for during the design phase.

Post-Drilling Dimensional Changes

Even after a successful drilling operation, the part can change. As the workpiece cools to ambient temperature, the drilled hole will become larger.

For true precision, allow the material to stabilize thermally before taking a final measurement.

Avoiding Material Smearing

The most common failure is smearing or melting, which creates a messy, inaccurate hole. This is almost always caused by a combination of two factors: a dull cutting tool and excessive drill speed.

Making the Right Choice for Your Goal

By tailoring your approach to your primary objective, you can mitigate the challenges of working with PTFE.

- If your primary focus is dimensional accuracy: Prioritize extremely sharp HSS tools, use moderate speeds, and allow the material to stabilize at room temperature before final measurement.

- If your primary focus is avoiding material failure: Concentrate on minimizing heat generation through proper drill speed and ensuring chips are cleared effectively to prevent melting.

- If you are designing the part: Acknowledge PTFE's properties by designing for looser tolerances whenever possible to account for its inherent thermal expansion and creep.

By respecting PTFE's unique properties instead of fighting them, you can achieve clean and precise results consistently.

Summary Table:

| Key Consideration | Why It Matters | Best Practice |

|---|---|---|

| Tool Sharpness | Dull tools tear material and generate excessive heat. | Use extremely sharp High-Speed Steel (HSS) drills. |

| Drill Speed | High RPMs cause heat buildup and melting. | Use moderate speeds to generate a continuous chip. |

| Clamping Pressure | PTFE deforms under excessive force, ruining dimensions. | Apply minimal, distributed pressure to hold the workpiece. |

| Drill Alignment | The soft material allows the drill to drift off-center. | Ensure the drill is perfectly perpendicular to the workpiece. |

Need Precision-Machined PTFE Components?

Drilling PTFE is just one step in creating high-performance components. At KINTEK, we specialize in manufacturing precision PTFE parts like seals, liners, and custom labware. Our expertise ensures your components are fabricated correctly from the start, avoiding the pitfalls of heat deformation and dimensional inaccuracy.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Let us handle the complex machining — Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers