Expanded PTFE gaskets are a cornerstone of sealing technology in a wide range of demanding sectors. They are most commonly found in the chemical processing, pharmaceutical, food and beverage, power generation, and petrochemical industries due to their unique combination of material properties.

The widespread adoption of expanded PTFE (ePTFE) gaskets isn't due to a single feature, but its unique blend of extreme chemical inertness, temperature resilience, and material purity. This makes it a highly versatile and reliable solution for the most critical sealing applications.

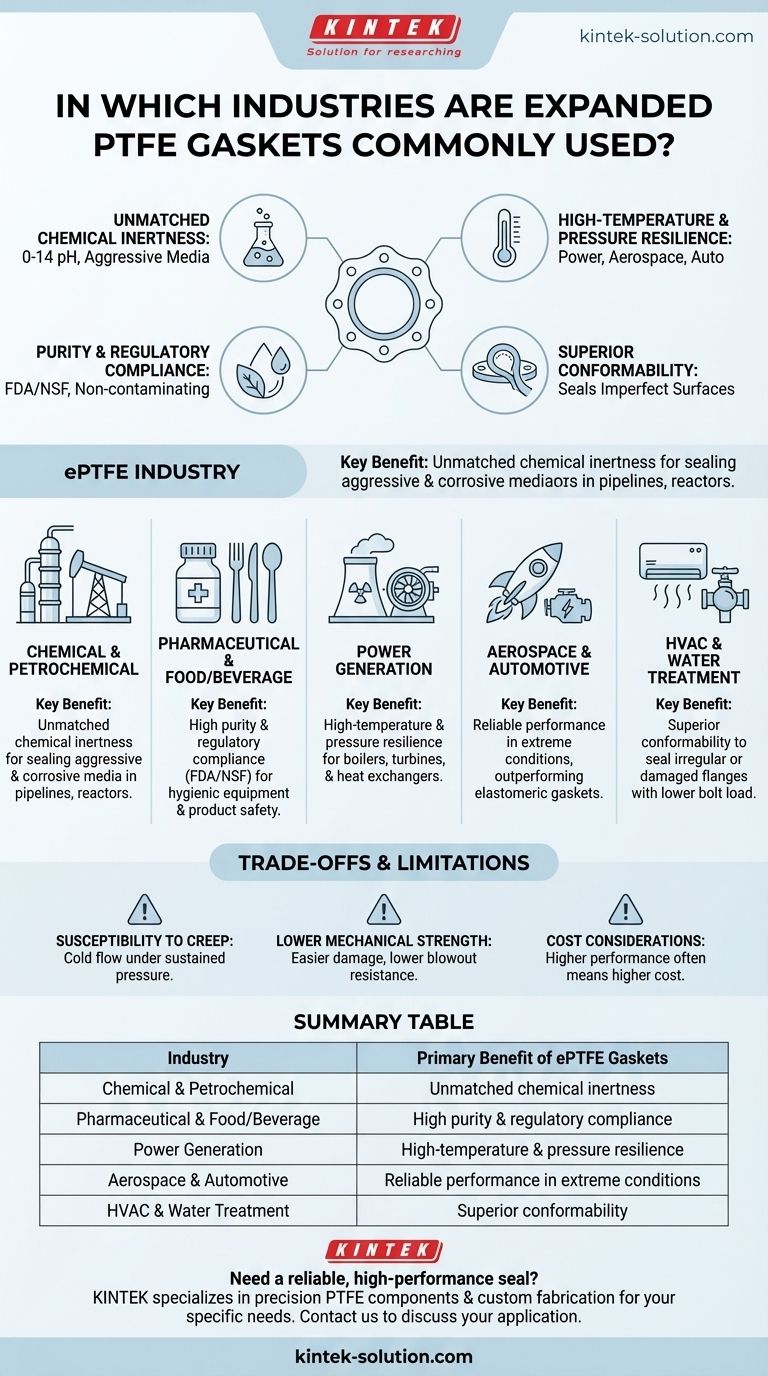

Why These Industries Rely on Expanded PTFE

The value of expanded PTFE gaskets lies in a set of core properties that directly solve the challenges faced by specific industries. Each industry leverages a different aspect of the material's performance.

Unmatched Chemical Inertness

Expanded PTFE is chemically inert across the entire 0-14 pH range. It will not degrade or react when exposed to even the most aggressive acids, solvents, and corrosive chemicals.

This property makes it the default choice for the chemical, petrochemical, and oil and gas industries. It ensures the integrity of seals in pipelines, reactors, and storage vessels containing harsh media.

Purity and Regulatory Compliance

The material is inherently pure, non-contaminating, odorless, and will not taint the media it contacts. It is frequently manufactured to be compatible with FDA and NSF standards.

This is non-negotiable for the pharmaceutical and food and beverage industries. Here, ePTFE is used to seal flanges, pump mounts, and manhole covers on hygienic equipment where product purity is paramount.

High-Temperature and Pressure Resilience

Expanded PTFE gaskets maintain their sealing integrity across a wide range of temperatures and pressures, outperforming many elastomeric gaskets that would fail in similar conditions.

This makes them essential in the power generation sector for sealing high-pressure boilers, turbines, and heat exchangers. It is also a key reason for their use in demanding aerospace and automotive applications.

Superior Conformability

The manufacturing process creates a soft, malleable material that conforms easily to irregular, pitted, or damaged flange surfaces. This allows it to create a tight seal with a lower bolt load than many other gasket types.

This benefit is leveraged across many sectors, including HVAC and water treatment, where perfect flange surfaces cannot always be guaranteed.

Common Applications Across Industries

While the reasons for choosing ePTFE vary, the applications themselves are often similar: creating a reliable seal between two bolted surfaces.

Sealing Pipelines and Flange Joints

This is the most common application across all industries. The gasket is placed between two pipe flanges to prevent the leakage of liquids or gases, from processed foods to volatile chemicals.

Equipment Sealing

Expanded PTFE is used to seal components on complex equipment. This includes heat exchangers, large container lids, pump mounts, and hydraulic and pneumatic systems where a durable, long-lasting seal is required.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means understanding the limitations of expanded PTFE gaskets.

Susceptibility to Creep

Like all PTFE materials, ePTFE can be subject to creep, or cold flow, over time. This is the tendency for the material to deform under sustained compressive stress, which can lead to a loss of bolt torque. This is a critical factor to manage in high-temperature or high-pressure applications.

Lower Mechanical Strength

Expanded PTFE is a soft material. While this aids its conformability, it also means it can be easily damaged by over-tightening or improper handling. It does not have the rigidity or blowout resistance of metallic or semi-metallic gaskets.

Cost Considerations

Expanded PTFE is often a higher-performance and, therefore, higher-cost option compared to standard rubber or non-asbestos fiber gaskets. The decision to use it must be weighed against the criticality of the application and the cost of potential failure.

Making the Right Choice for Your Application

Your specific goal will determine if expanded PTFE is the optimal choice.

- If your primary focus is chemical resistance: Expanded PTFE is a leading choice for safely sealing aggressive and corrosive media.

- If your primary focus is product purity: Its FDA-compliant and inert nature makes it ideal for food, beverage, and pharmaceutical applications.

- If your primary focus is sealing damaged or uneven flanges: The soft, conformable nature of ePTFE provides an effective seal where more rigid gaskets would fail.

- If your primary focus is high-temperature stability: It performs reliably in environments like power plants and steam systems where many other materials would degrade.

By understanding these core properties and trade-offs, you can confidently determine if expanded PTFE gaskets provide the reliable, long-lasting seal your critical systems require.

Summary Table:

| Industry | Primary Benefit of ePTFE Gaskets |

|---|---|

| Chemical & Petrochemical | Unmatched chemical inertness for aggressive media |

| Pharmaceutical & Food/Beverage | High purity and regulatory compliance (FDA, NSF) |

| Power Generation | High-temperature and pressure resilience |

| Aerospace & Automotive | Reliable performance in extreme conditions |

| HVAC & Water Treatment | Superior conformability for imperfect flanges |

Need a reliable, high-performance seal for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components, including expanded PTFE gaskets, seals, liners, and custom labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact sealing solution your industry demands.

Whether you're in semiconductor manufacturing, medical technology, laboratory research, or industrial processing, we prioritize precision production to meet your strictest requirements for chemical resistance, purity, and temperature resilience.

Contact KINTEK today to discuss your specific needs and discover how our PTFE solutions can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications