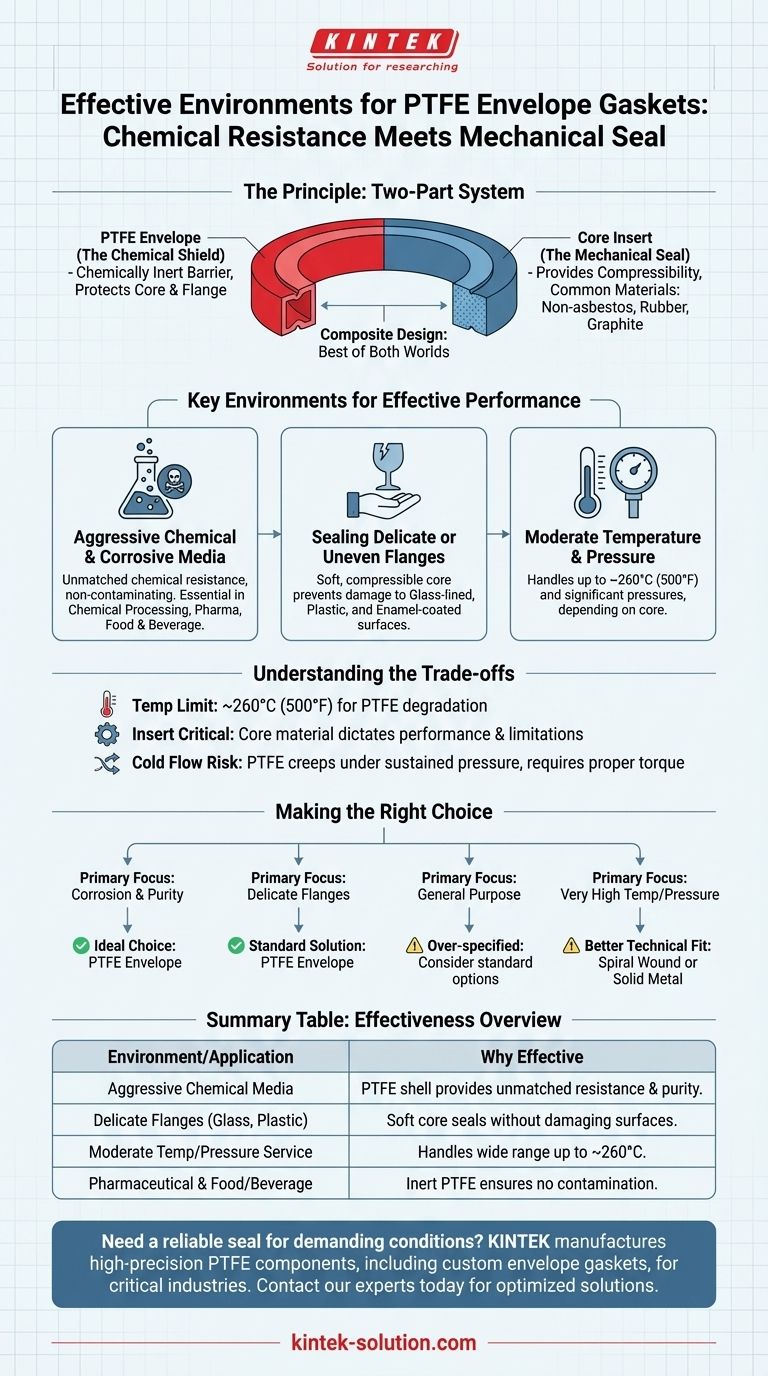

In short, PTFE envelope gaskets are designed for environments where exceptional chemical resistance must be combined with the mechanical sealing properties of a traditional gasket. They are most effective in highly corrosive applications, across a wide temperature range, and in systems with delicate flange surfaces like glass-lined or plastic piping.

The core strength of a PTFE envelope gasket lies in its composite design. By encasing a resilient core material within a chemically inert PTFE shell, it provides the best of both worlds: the unparalleled corrosion resistance of PTFE and the mechanical strength and compressibility of the insert.

The Principle: How an Envelope Gasket Works

A PTFE envelope gasket is not a single material but a two-part system. Understanding this construction is key to knowing where and why it is so effective.

The PTFE Envelope (The Chemical Shield)

The outer layer, or envelope, is made from PTFE (polytetrafluoroethylene). This material is famous for being almost completely chemically inert.

This PTFE shell acts as a barrier, protecting the gasket's core and the flange joint from attack by aggressive media, from strong acids to solvents.

The Core Insert (The Mechanical Seal)

Inside the envelope is a flexible, compressible insert material. This core provides the mechanical force needed to create a tight seal.

Common insert materials include non-asbestos fibers, rubber, graphite, or corrugated metal. The choice of insert determines the gasket's pressure and temperature ratings, as well as its ability to conform to surface irregularities.

Key Environments for Effective Performance

The dual-material design makes PTFE envelope gaskets uniquely suited for specific, challenging industrial applications.

Aggressive Chemical and Corrosive Media

This is the primary application. The PTFE envelope ensures the gasket will not degrade, contaminate the process media, or fail when exposed to harsh chemicals.

This makes them essential in chemical processing, pharmaceutical production, and food and beverage applications where purity and resistance to corrosion are non-negotiable.

Sealing Delicate or Uneven Flanges

Standard solid gaskets can crack or damage fragile flange surfaces. Envelope gaskets solve this problem.

They are the preferred choice for sealing glass-lined steel, plastic, and enamel-coated flanges. The soft, compressible nature of the insert and the slick PTFE surface create a strong seal without applying excessive, damaging stress to the flange face.

Moderate Temperature and Pressure Service

While not designed for extreme pressures and temperatures like a solid metal gasket, envelope gaskets perform reliably across a broad operational window.

Depending on the core material, they can typically handle temperatures up to ~260°C (500°F) and withstand significant bolt loads and internal pressures without breaking.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are a specialized solution with specific limitations to consider.

Temperature Limitations of PTFE

The primary constraint is the temperature limit of the PTFE material itself, which is around 260°C (500°F). Beyond this point, PTFE can begin to degrade. For higher-temperature service, other materials like graphite become necessary.

The Critical Role of the Insert

The gasket's overall performance is heavily dependent on the core insert. A rubber core offers excellent compressibility but lower temperature resistance, while a graphite or metal core can handle higher temperatures and pressures but may be less forgiving on uneven surfaces. Selecting the wrong insert can lead to seal failure.

Susceptibility to Cold Flow

PTFE as a material can be prone to "cold flow" or creep, where it slowly deforms under sustained pressure. The gasket's core insert provides resistance to this, but it remains a consideration in high-load applications, requiring proper bolt torque procedures.

Making the Right Choice for Your Application

Use the gasket's unique properties to guide your decision.

- If your primary focus is corrosion resistance: A PTFE envelope gasket is an ideal choice, especially when process purity is also a concern.

- If your primary focus is sealing delicate flanges: This is the standard solution for glass-lined, plastic, or ceramic systems to prevent breakage.

- If your primary focus is a general-purpose seal: A PTFE envelope gasket may be over-specified; a standard non-asbestos or rubber gasket might be more cost-effective if there is no chemical risk.

- If your primary focus is very high temperature or pressure: A solution like a spiral wound gasket with graphite filler or a solid metal gasket is likely a better technical fit.

By understanding its two-part construction, you can confidently deploy this gasket precisely where its unique combination of chemical and mechanical properties will deliver the most reliable performance.

Summary Table:

| Environment/Application | Why PTFE Envelope Gaskets are Effective |

|---|---|

| Aggressive Chemical Media | PTFE shell provides unmatched chemical resistance and process purity. |

| Delicate Flanges (Glass, Plastic) | Soft, compressible core seals effectively without damaging surfaces. |

| Moderate Temp/Pressure Service | Composite design handles a wide operational range (up to ~260°C / 500°F). |

| Pharmaceutical & Food/Beverage | Inert PTFE ensures no contamination of sensitive processes. |

Need a reliable seal for demanding conditions?

PTFE envelope gaskets are a specialized solution for industries where failure is not an option. At KINTEK, we understand the critical balance between chemical resistance and mechanical performance.

We manufacture high-precision PTFE components, including custom envelope gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype for a new application or high-volume production, our expertise ensures you get a gasket optimized for your specific environment—corrosive media, delicate flanges, and beyond.

Let's discuss your application requirements. Contact our experts today for a solution that guarantees performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications