Expanded PTFE (ePTFE) gaskets are particularly effective in two distinct and challenging types of environments: those with highly aggressive chemicals and those with imperfect or delicate flange surfaces. Their unique material structure allows them to create a reliable seal where more rigid gaskets would fail, making them a premier problem-solving material in demanding industrial settings.

The true value of expanded PTFE is not just its chemical resistance, which is inherent to all PTFE, but its exceptional ability to conform and seal under difficult mechanical conditions like warped, pitted, or fragile flanges.

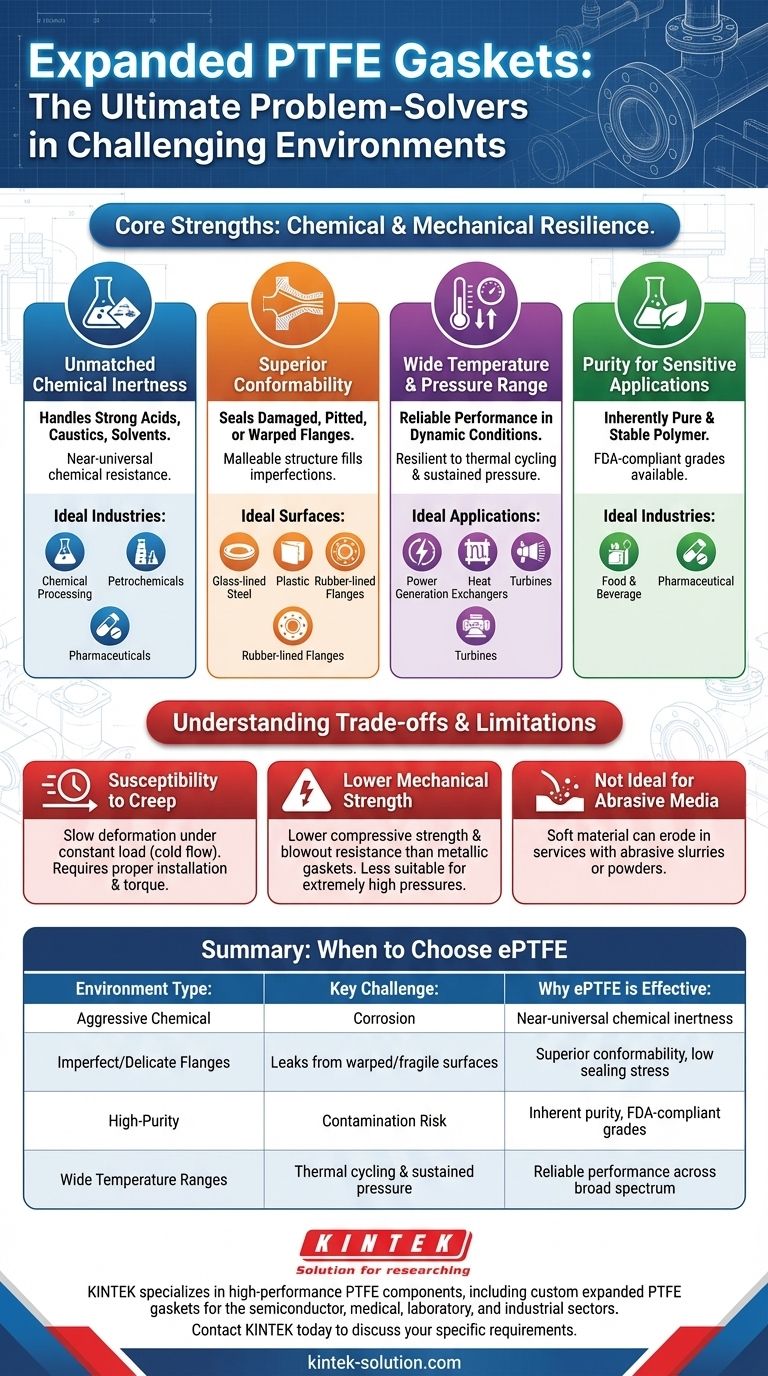

The Core Strengths of ePTFE: Chemical and Mechanical Resilience

Expanded PTFE gaskets solve sealing problems that often have both a chemical and a physical component. Their effectiveness stems from a unique combination of material properties.

Unmatched Chemical Inertness

ePTFE is chemically inert across nearly the entire pH scale. It can handle strong acids, caustics, solvents, and other aggressive process fluids that would degrade most other gasket materials.

This makes it a standard choice in industries like chemical processing, petrochemicals, and pharmaceuticals, where process media are highly corrosive.

Superior Conformability

This is the key differentiator for ePTFE. The expansion process creates a soft, malleable microstructure that allows the gasket to compress easily and fill in surface imperfections.

It is highly effective for sealing damaged, pitted, or warped flanges. It also excels on delicate flange materials like glass-lined steel, plastic, or rubber-lined flanges, where high bolt loads would cause damage.

Wide Temperature and Pressure Range

ePTFE gaskets perform reliably across a broad spectrum of temperatures and pressures. This makes them suitable for dynamic operating conditions found in many industrial processes.

Applications in power generation, such as sealing heat exchangers, turbines, and boilers, benefit from this resilience to thermal cycling and sustained pressure.

Purity for Sensitive Applications

Because PTFE is an inherently pure and stable polymer, ePTFE gaskets are ideal for environments where contamination is a critical concern.

They are widely used in the food and beverage and pharmaceutical industries, with many grades carrying FDA approval for contact with consumables.

Understanding the Trade-offs and Limitations

While highly effective, ePTFE is not a universal solution. Understanding its limitations is key to using it correctly and avoiding misapplication.

Susceptibility to Creep

Like all PTFE materials, ePTFE can be subject to creep, or cold flow, where the material slowly deforms under a constant load. While its structure mitigates this better than solid PTFE, it is still a factor.

Proper installation and bolt torque procedures are critical to maintaining a long-term, leak-free seal, especially in high-temperature applications.

Lower Mechanical Strength

Compared to semi-metallic or metallic gaskets, ePTFE has lower compressive strength and blowout resistance. It is a soft material by design.

For extremely high-pressure pipeline applications that do not involve corrosive media or flange imperfections, a more rigid gasket like a spiral wound gasket may be a more robust choice.

Not Ideal for Abrasive Media

The soft nature of ePTFE means it is not well-suited for sealing services containing abrasive slurries or powders, which can erode the gasket material over time.

Making the Right Choice for Your Goal

Select your gasket material based on the most demanding aspect of your application.

- If your primary focus is sealing aggressive chemicals: ePTFE is a top-tier choice due to its near-universal chemical resistance, protecting both your process and your equipment.

- If your primary focus is sealing imperfect or delicate flanges: The unique conformability of ePTFE makes it a superior solution for creating a reliable seal on glass-lined, plastic, or damaged steel surfaces.

- If your primary focus is high-purity applications: The inert nature and available FDA-compliant grades of ePTFE make it a standard choice for pharmaceutical and food processing environments.

- If your primary focus is extreme pressure without other challenges: Objectively evaluate whether a semi-metallic gasket might offer better long-term creep and blowout resistance for your specific conditions.

Ultimately, deploying an expanded PTFE gasket is a strategic decision to ensure seal integrity where chemical compatibility and mechanical adaptability are paramount.

Summary Table:

| Environment Type | Key Challenge | Why ePTFE is Effective |

|---|---|---|

| Aggressive Chemical | Corrosion from acids, caustics, solvents | Near-universal chemical inertness |

| Imperfect/Delicate Flanges | Leaks from warped, pitted, or fragile surfaces | Superior conformability and low sealing stress |

| High-Purity | Risk of product contamination | Inherent material purity, FDA-compliant grades available |

| Wide Temperature Ranges | Thermal cycling from cryogenic to high heat | Reliable performance across a broad temperature spectrum |

Need a reliable seal for your most demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom expanded PTFE gaskets. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering precision and reliability from prototype to high-volume production.

Our ePTFE gaskets are engineered to solve your toughest sealing challenges, ensuring leak-free operation with aggressive chemicals and on imperfect flange surfaces.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries