In chemical applications, PTFE balls are indispensable in industries where purity and resistance to aggressive substances are non-negotiable. They are most commonly used in chemical processing, pharmaceuticals, food and beverage manufacturing, and semiconductor fabrication due to their unparalleled chemical inertness.

The core reason PTFE is specified for these critical applications is its near-universal chemical resistance. This single property ensures that components made from PTFE will not degrade when exposed to harsh chemicals, nor will they contaminate the process fluids they contact.

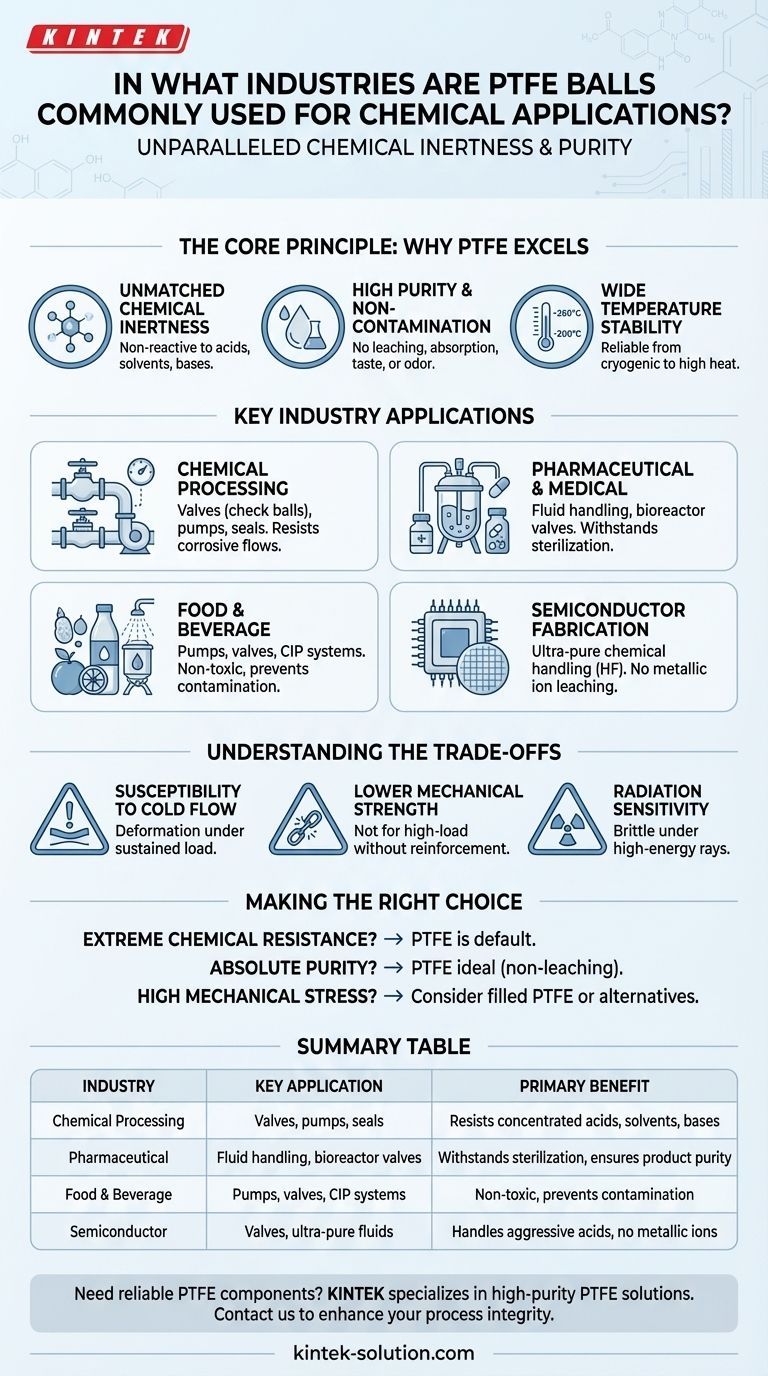

The Core Principle: Why PTFE Excels with Chemicals

The selection of a material for chemical handling is a critical engineering decision. PTFE (Polytetrafluoroethylene) consistently emerges as a top choice because its fundamental molecular structure gives it a unique combination of beneficial properties.

Unmatched Chemical Inertness

The bond between carbon and fluorine atoms in PTFE is exceptionally strong and stable. This makes the material non-reactive to nearly all industrial chemicals, including concentrated acids, aggressive solvents, and caustic bases across a wide temperature range.

High Purity and Non-Contamination

PTFE is an inherently pure polymer. It does not leach chemicals, absorb process fluids, or impart any taste or odor. This is an absolute requirement in industries like pharmaceuticals and food production, where even trace amounts of contamination can ruin a batch or pose a health risk.

Wide Temperature Stability

Many chemical processes operate at elevated temperatures. PTFE maintains its structural integrity and chemical resistance from cryogenic levels up to approximately 260°C (500°F), ensuring reliable performance where other materials would fail.

Key Industry Applications Breakdown

The theoretical properties of PTFE translate directly into practical, high-stakes applications across several key industries. Each sector leverages its unique characteristics to solve specific challenges.

The Chemical Processing Industry

This is the most direct application. PTFE balls are used extensively in valves (as check balls), pumps, and seals that manage the flow of highly corrosive materials. They ensure a tight seal without being degraded by the substance being transported.

Pharmaceutical and Medical Sectors

In pharmaceutical manufacturing, sterility and purity are paramount. PTFE balls are used in fluid handling systems and valves for bioreactors because they can withstand aggressive cleaning agents and steam sterilization processes while ensuring the final product remains uncontaminated.

Food and Beverage Manufacturing

Similar to the pharmaceutical industry, the food and beverage sector relies on PTFE for its non-toxic, non-contaminating properties. It is used in pumps and valves that handle everything from acidic fruit juices to fatty oils and the caustic solutions used for clean-in-place (CIP) systems.

Semiconductor Fabrication

The manufacturing of microchips involves some of the most aggressive and ultra-pure chemicals, such as hydrofluoric acid. PTFE is one of the few materials that can handle these substances without degrading or introducing metallic ion contamination, making it essential for valves and fluid transport systems in this industry.

Understanding the Trade-offs and Limitations

While its chemical properties are extraordinary, PTFE is not the solution for every engineering problem. Understanding its limitations is key to using it effectively.

Susceptibility to Cold Flow

PTFE is a relatively soft material. Under a constant, sustained load (like a high-pressure seal), it can slowly deform over time in a process known as "creep" or "cold flow." This must be accounted for in high-pressure mechanical designs.

Lower Mechanical Strength

Compared to metals or other engineering plastics, PTFE has lower tensile strength and abrasion resistance. It is not suitable for high-load structural applications unless it is reinforced with fillers like glass or carbon.

Radiation Sensitivity

High-energy radiation, such as gamma rays, can break down the polymer chains in PTFE, causing it to become brittle and lose its desirable properties. This can be a limiting factor in applications involving radiation-based sterilization.

Making the Right Choice for Your Application

Selecting the right material requires balancing chemical needs with mechanical and environmental demands.

- If your primary focus is extreme chemical resistance: PTFE is the default choice for handling the most aggressive acids, bases, and organic solvents.

- If your primary focus is maintaining absolute purity: PTFE's non-leaching and non-absorbent nature makes it ideal for pharmaceutical, food, and semiconductor applications.

- If your application involves high mechanical stress or abrasion: Consider using a filled grade of PTFE or an alternative high-performance polymer if load-bearing is the dominant requirement.

Ultimately, PTFE's unique chemical inertness ensures operational reliability and product purity in the world's most chemically demanding environments.

Summary Table:

| Industry | Key Application of PTFE Balls | Primary Benefit |

|---|---|---|

| Chemical Processing | Valves, pumps, and seals | Resists concentrated acids, solvents, and bases |

| Pharmaceutical | Fluid handling systems, bioreactor valves | Withstands sterilization, ensures product purity |

| Food & Beverage | Pumps and valves for ingredients and CIP systems | Non-toxic, prevents contamination and odor/taste transfer |

| Semiconductor | Valves and fluid transport for ultra-pure chemicals | Handles aggressive acids like HF without metallic ion leaching |

Need reliable PTFE components for your critical chemical applications?

KINTEK specializes in manufacturing high-purity PTFE components—including seals, liners, labware, and custom balls—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume production, ensuring your systems operate with maximum reliability and contamination-free performance.

Contact us today to discuss your specific requirements and learn how our PTFE solutions can enhance your process integrity.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction