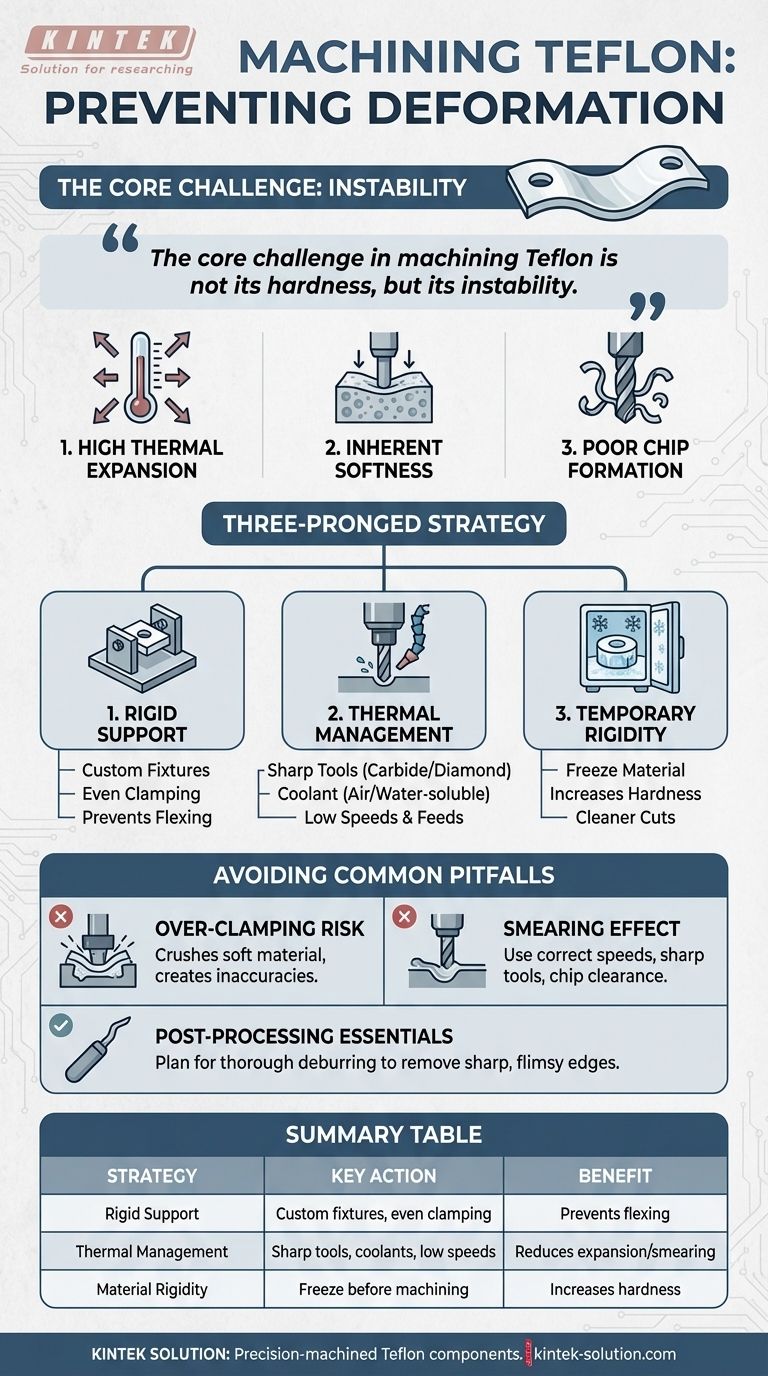

To prevent Teflon parts from deforming during machining, you must use a three-pronged strategy. This involves providing robust physical support with appropriate fixtures, actively managing heat with sharp tools and coolants, and in some cases, temporarily increasing the material's hardness by freezing it prior to cutting. These steps directly counteract Teflon's inherent softness and its extremely high rate of thermal expansion.

The core challenge in machining Teflon is not its hardness, but its instability. Because it is soft and expands significantly with heat, the key to precision is controlling the machining environment to minimize stress and thermal variation on the part.

The Core Challenge: Why Teflon Deforms So Easily

To machine Teflon without deformation, you must first understand the properties that make it so challenging. The material's unique characteristics are the direct cause of common machining failures.

High Thermal Expansion

Teflon (PTFE) has a very high coefficient of thermal expansion. This means even a small amount of heat generated by tool friction will cause the material to expand significantly.

This expansion can ruin dimensional accuracy, causing a part that was within tolerance at cutting temperature to be out of tolerance once it cools.

Inherent Softness and Lack of Rigidity

Teflon is an exceptionally soft material. Under the pressure of a cutting tool, it is prone to compressing, flexing, and bending rather than cutting cleanly.

This lack of rigidity makes it difficult to hold securely without distortion and can lead to a "smearing" effect on the surface instead of a clean finish.

Poor Chip Formation

Unlike metals that form clean, predictable chips that carry heat away, Teflon produces stringy, gummy chips.

These chips do not break easily and can wrap around the tool, increasing friction, generating more heat, and compromising the surface finish.

Key Strategies for Preventing Deformation

A successful approach to machining Teflon focuses on mitigating its inherent weaknesses through careful preparation, tooling, and environmental control.

Strategy 1: Ensure Rigid Support

Properly supporting the workpiece is the first line of defense against deformation.

Use custom fixtures that support as much of the part as possible. This prevents the material from flexing or moving away from the cutting tool, ensuring dimensional stability.

Strategy 2: Master Thermal Management

Controlling heat is arguably the most critical factor for achieving tight tolerances with Teflon.

Use extremely sharp cutting tools, preferably made from cemented carbide or diamond, with polished surfaces. Sharp edges reduce friction, which is the primary source of heat.

Employ a compatible coolant like pressurized air or a water-soluble fluid. This actively pulls heat away from the cutting zone before it can cause the material to expand.

Utilize low cutting speeds and feed rates. This minimizes the energy—and therefore heat—put into the part during the machining process.

Strategy 3: Temporarily Increase Rigidity

For parts requiring very high precision, you can alter the material's state to make it more stable for machining.

Temporarily freezing the material is a highly effective technique. Cooling the Teflon makes it harder and more rigid, allowing it to be cut more cleanly with significantly less deformation and smearing.

Understanding the Trade-offs and Common Pitfalls

While these strategies are effective, they require careful application. A lack of awareness of the potential pitfalls can lead to different kinds of part failure.

The Risk of Over-Clamping

While robust fixtures are essential, over-tightening them is a common mistake.

Because Teflon is so soft, excessive clamping pressure can easily crush or distort the part before a single cut is even made, creating inaccuracies from the very start.

The Smearing Effect

Even with good technique, smearing can occur. This happens when the tool pushes and melts the material instead of shearing it cleanly.

To minimize smearing, ensure your feed rates are correct for the tool, your tools are exceptionally sharp, and you have proper chip clearance. Post-processing techniques like bead blasting can also smooth smeared surfaces.

The Need for Post-Processing

Understand that achieving a perfect finish directly off the machine can be difficult.

Plan for a thorough deburring process, as Teflon can form sharp, flimsy edges that affect part performance or assembly. These must be carefully removed.

A Checklist for Machining Teflon Successfully

Your specific approach should be tailored to the primary goal of your project. Use these guidelines to prioritize your efforts for consistent, high-quality results.

- If your primary focus is tight tolerances: Prioritize thermal stability by using effective coolants and seriously consider freezing the material before machining.

- If your primary focus is a clean surface finish: Use extremely sharp, polished tools (like cemented carbide or diamond) and maintain a slow, consistent feed rate to prevent smearing.

- If your primary focus is preventing flexing on thin-walled parts: Design custom fixtures that provide complete and even support across the entire workpiece.

By respecting Teflon's unique properties with the right preparation and technique, you can achieve precise and reliable results on every part.

Summary Table:

| Strategy | Key Action | Benefit |

|---|---|---|

| Rigid Support | Use custom fixtures with even clamping | Prevents flexing and movement during cutting |

| Thermal Management | Sharp tools, coolants, low speeds | Reduces heat-induced expansion and smearing |

| Material Rigidity | Freeze Teflon before machining | Temporarily increases hardness for cleaner cuts |

Need precision-machined Teflon components that hold their shape? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for semiconductor, medical, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are machined with the precise techniques needed to prevent deformation. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What issue can arise when PTFE gaskets are subjected to external pressure? Prevent Seal Failure and Deformation

- What makes PTFE an excellent material for insulation in wires and cables? Unmatched Performance for Extreme Conditions

- What types of media can PTFE lined ball valves handle? Handle Corrosive Fluids Safely

- What makes ePTFE suitable for filtration applications? Unlock Superior Performance for Demanding Environments

- Why is CNC machined PTFE gaining importance in the biomedical field? Unlock Safer, High-Precision Medical Devices

- What are the main applications of PTFE lined valves? Control Corrosive & High-Purity Fluids

- What lubrication characteristics does PTFE offer for mechanical seals? Achieve Oil-Free, Low-Friction Sealing

- What are the key differences between monoaxial and multidirectional expanded PTFE? Choose the Right ePTFE for Your Seal