To preserve the integrity and performance of PTFE gaskets, you must store them in a clean, dry, and cool environment. They need to be kept away from direct sunlight, extreme temperatures, and any reactive chemicals or oils. Storing them flat in their original, sealed packaging is the ideal method to prevent physical distortion and surface contamination, ensuring they are ready for service.

The challenge with storing PTFE gaskets is not about preventing chemical breakdown—the material is incredibly stable. The real goal is to protect their physical shape and surface purity, as distortion or contamination are the primary causes of sealing failure.

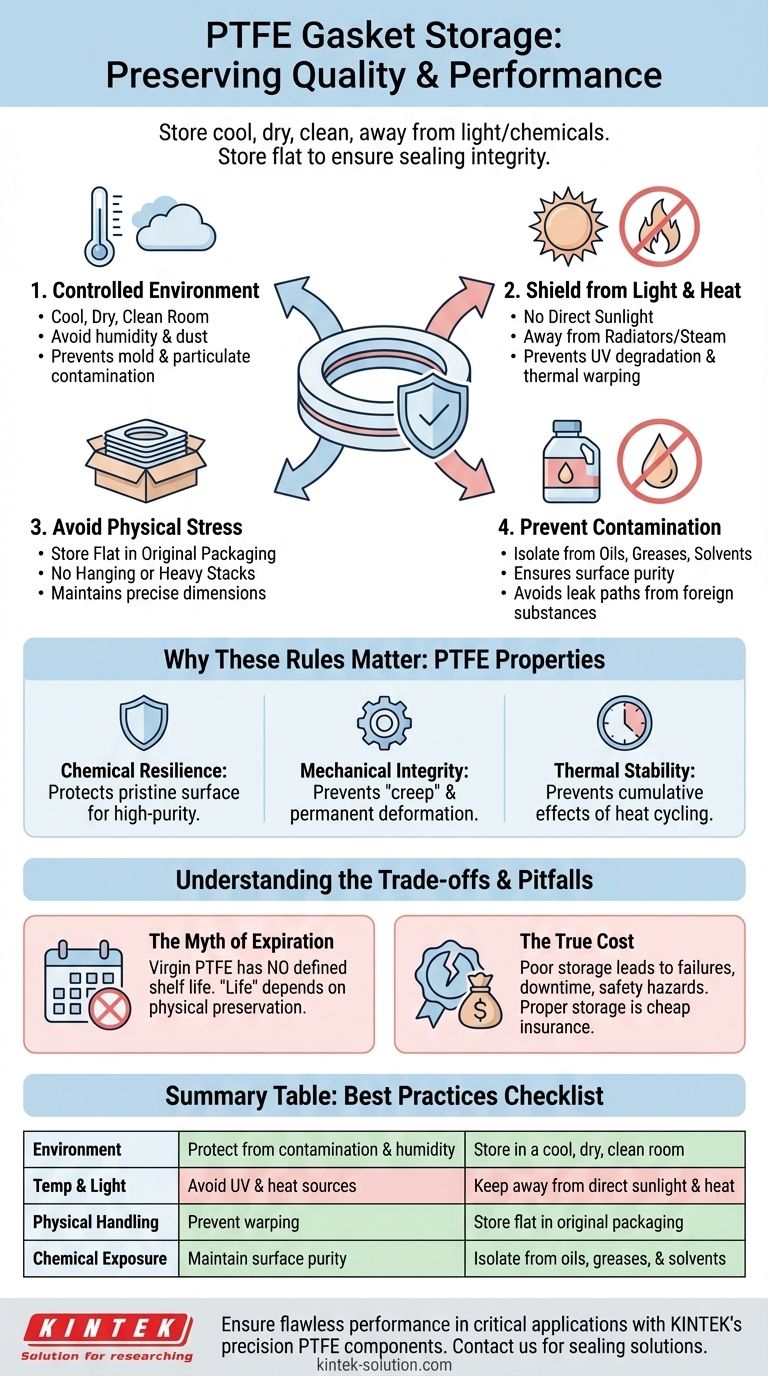

The Core Principles of Gasket Storage

Proper storage is a critical but often overlooked aspect of joint integrity. For PTFE, the rules are straightforward and are designed to protect the material's unique properties.

Environmental Control is Paramount

A controlled environment is the foundation of proper storage. The ideal location is a cool, dry, and clean room.

Excess humidity can promote the growth of mold on packaging materials, and airborne dust or dirt can settle on a gasket's surface. These contaminants can compromise the seal face when the gasket is installed.

Shielding from Sunlight and Heat

PTFE has excellent temperature resistance during operation, but for long-term storage, stability is key. Keep gaskets away from direct sunlight and sources of heat like radiators or steam pipes.

Ultraviolet (UV) radiation from the sun can cause slow surface degradation and discoloration over time. Extreme heat can cause the material to soften and warp, permanently altering its shape.

Avoiding Physical Stress and Distortion

PTFE is a flexible material designed to compress and create a seal. This flexibility also makes it susceptible to distortion if stored improperly.

Never hang PTFE gaskets on pegs or stack heavy items on top of them. The best practice is to store them flat on a shelf, preferably in their original packaging, to maintain their precise dimensions.

Preventing Chemical Contamination

While one of PTFE's greatest strengths is its chemical inertness, you must still store it away from oils, greases, solvents, and other chemicals.

The concern here is not a chemical reaction with the PTFE itself, but surface contamination. Any foreign substance on the gasket face can create an imperfection in the seal, leading to a potential leak path.

Why These Rules Matter: A Look at PTFE Properties

Understanding the "why" behind these storage rules is rooted in the exceptional properties of Polytetrafluoroethylene (PTFE).

Protecting Chemical Resilience

PTFE is famously non-reactive and can withstand nearly all industrial chemicals. The storage rule to keep them away from chemicals is a best practice to ensure the gasket surface remains pristine, which is especially critical in high-purity applications like food or pharmaceuticals.

Preserving Mechanical Integrity

A gasket's ability to seal depends on its ability to compress uniformly. PTFE's flexibility allows this, but it also makes it vulnerable to "creep" or permanent deformation under sustained load. Storing gaskets flat and without weight on them preserves their original, manufactured shape, ensuring a perfect fit and reliable seal.

Maintaining Thermal Stability

PTFE performs reliably in extreme temperatures, often cited from -200°C to 260°C (-328°F to 500°F). However, these are service temperatures. Long-term storage in a stable, cool environment prevents the slow, cumulative effects of thermal cycling or excessive heat, which can lead to warping.

Understanding the Trade-offs and Common Pitfalls

While PTFE is robust, overlooking storage can lead to predictable failures.

The Myth of an Expiration Date

Unlike rubber or elastomer gaskets which can chemically degrade over time, virgin PTFE does not have a defined shelf life. Its chemical structure is exceptionally stable.

The "life" of a stored PTFE gasket is determined entirely by how well its physical form and cleanliness have been preserved. A gasket stored poorly for one year may be less reliable than one stored properly for ten years.

The True Cost of Poor Storage

The cost of a single gasket is minimal compared to the cost of a failure. A warped or contaminated gasket may appear usable but can lead to a premature leak.

This can result in costly downtime, lost product, and significant safety hazards. Proper storage is an inexpensive insurance policy against these risks.

Considering Different PTFE Types

The principles outlined here apply to all major types of PTFE gaskets, including virgin, expanded, and modified/filled versions. The core material properties that demand these storage practices are consistent across the family of products.

Making the Right Choice for Your Goal

Use this checklist to ensure your storage practices align with your operational needs.

- If your primary focus is long-term reliability: Store gaskets flat in their original, sealed packaging within a climate-controlled storeroom to prevent any physical distortion over time.

- If your primary focus is use in sensitive applications (Food/Pharma): Prioritize sealed, clean storage to prevent any particulate or chemical contamination that could compromise the purity of the end product.

- If your primary focus is managing a high-volume inventory: Implement a "first-in, first-out" (FIFO) system, not because of chemical expiration, but to ensure consistent quality and handling across all stock.

Proper storage is a simple discipline that ensures your PTFE gaskets will deliver the high performance and reliability you expect when they are put into service.

Summary Table:

| Storage Factor | Key Consideration | Best Practice |

|---|---|---|

| Environment | Protect from contamination and humidity | Store in a cool, dry, clean room |

| Temperature & Light | Avoid UV radiation and heat sources | Keep away from direct sunlight and heat |

| Physical Handling | Prevent warping and deformation | Store flat in original packaging |

| Chemical Exposure | Maintain surface purity | Isolate from oils, greases, and solvents |

Ensure your PTFE gaskets perform flawlessly in critical applications. At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial industries. Whether you need custom prototypes or high-volume orders, our expertise in PTFE fabrication guarantees components that meet the strictest quality standards. Contact us today to discuss your specific requirements and discover how KINTEK can support your sealing and contamination-control needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE skiving performed? A Guide to Precision PTFE Film Manufacturing

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- What benefits do spring energized Teflon seals provide? Unlock Reliable Sealing in Extreme Conditions

- What are the best applications for standard PTFE gaskets? Ideal for Chemical & High-Temp Sealing

- What are the media resistance properties of PTFE with fillers? Retains Chemical Inertness While Boosting Durability

- Why are PTFE Liners preferred for catheter systems? Superior Lubricity, Biocompatibility & Safety

- What are lined pipes and how do they work? Achieve Superior Chemical Resistance at a Lower Cost

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance