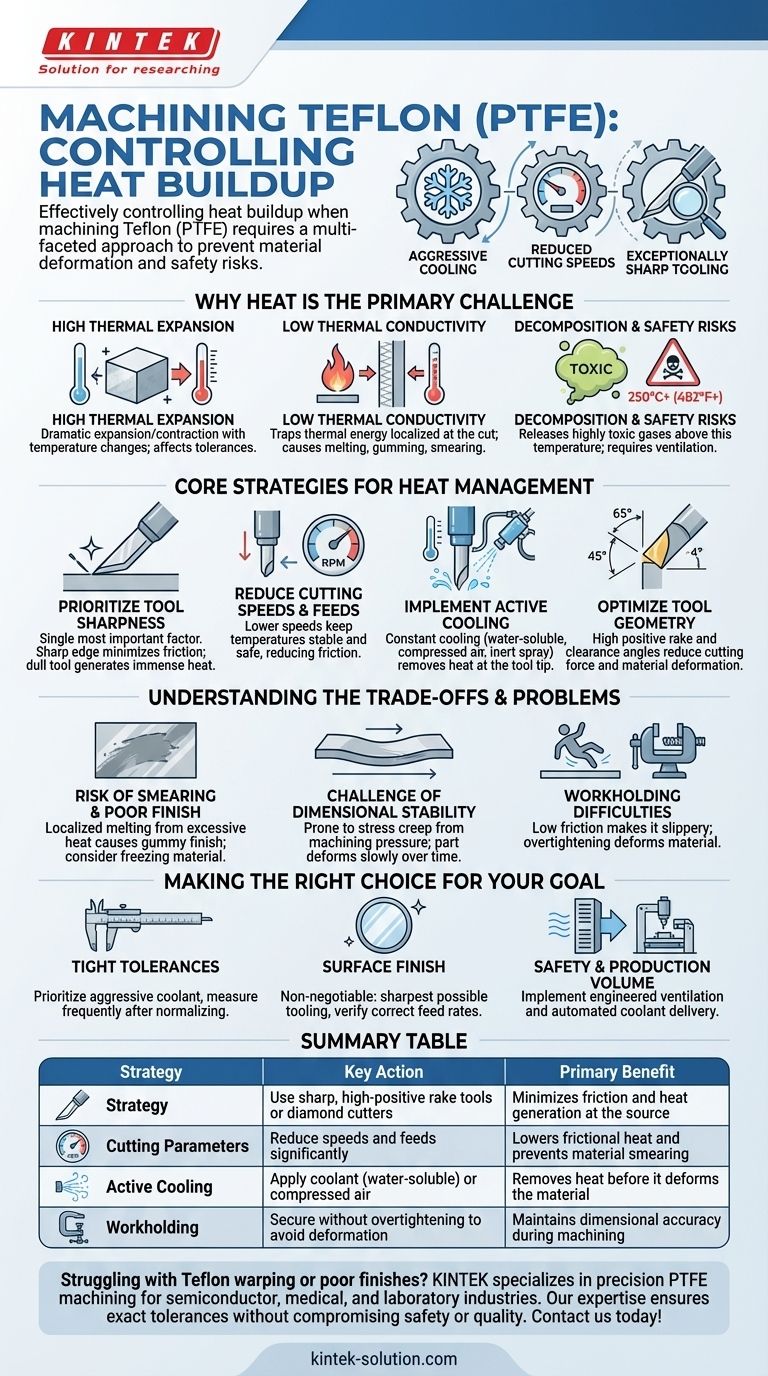

To effectively control heat buildup when machining Teflon (PTFE), you must use a multi-faceted approach combining aggressive cooling, significantly reduced cutting speeds, and exceptionally sharp tooling. These methods work together to both minimize the generation of frictional heat and actively remove any heat that is created before it can deform the material.

Teflon's core challenge is its combination of low thermal conductivity and a high rate of thermal expansion. Heat gets trapped at the cutting point, causing the material to warp, smear, and lose dimensional accuracy, making heat prevention more critical than heat removal.

Why Heat Is the Primary Challenge with Teflon

Understanding the material's properties reveals why heat management is not just a best practice, but an absolute necessity for successful machining.

High Thermal Expansion

Teflon expands and contracts dramatically with even minor temperature changes. A part machined to precise dimensions at an elevated temperature will be out of tolerance once it cools to room temperature.

Low Thermal Conductivity

Unlike metals, Teflon is an excellent insulator. It does not dissipate heat away from the cutting tool. This traps thermal energy in a very localized area, leading to immediate melting, gumming, and smearing instead of a clean chip.

Decomposition and Safety Risks

Most critically, if Teflon is heated above 250°C (482°F), it begins to decompose. This process releases highly toxic gases, creating a significant health hazard that necessitates proper ventilation and strict temperature control.

Core Strategies for Heat Management

A successful strategy focuses on preventing heat from being generated in the first place, and then managing what little is unavoidable.

Prioritize Tool Sharpness

This is the single most important factor. A sharp cutting edge cleanly shears the material, minimizing friction and pressure. A dull tool will plow through the Teflon, generating immense frictional heat.

Consider specialized tools like diamond cutters for superior performance and edge longevity.

Reduce Cutting Speeds and Feeds

High cutting speeds directly translate to high friction and heat. You must use slower speeds and appropriate feed rates compared to other plastics or metals to keep temperatures in a stable, safe range.

Implement Active Cooling

Constant cooling is non-negotiable. It removes the heat generated at the tool tip before it can build up in the workpiece and cause dimensional instability.

Effective methods include flooding with water-soluble coolants, using compressed air for a clean process, or applying chemically inert cooling sprays.

Optimize Tool Geometry

Using tools with high positive rake and clearance angles reduces the force required to make a cut. This lessens material deformation and, consequently, the heat generated by the process.

Understanding the Trade-offs and Associated Problems

Failing to manage heat and Teflon's other properties leads to predictable failures.

The Risk of Smearing and Poor Finish

Localized melting at the tool tip is the primary cause of a smeared, "gummy" surface finish. This is a direct result of excessive heat from a dull tool or improper speeds.

As a specialized solution, some operations temporarily freeze the material to increase its hardness and promote cleaner shearing.

The Challenge of Dimensional Stability

Beyond immediate thermal expansion, Teflon is prone to stress creep. The pressure and heat from machining can introduce internal stresses that cause the part to slowly deform over time, even after the job is complete.

Workholding Difficulties

Teflon's low coefficient of friction makes it notoriously slippery and difficult to clamp securely. Overtightening a vise to compensate can easily deform the soft material, especially as it warms up, leading to inaccurate cuts.

Making the Right Choice for Your Goal

Select your primary strategy based on the most critical outcome for your specific application.

- If your primary focus is tight tolerances: Prioritize aggressive, consistent coolant application and measure the part frequently, allowing it to normalize to room temperature before final measurements.

- If your primary focus is surface finish: Your non-negotiable first step is using the sharpest possible tooling, followed by verifying the correct feed rates to ensure a clean chip is formed.

- If your primary focus is safety and production volume: Implement engineered ventilation systems and an automated coolant delivery system to prevent overheating and hazardous off-gassing.

Ultimately, mastering Teflon machining means treating the material not as a typical plastic, but as a unique thermal management challenge.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Tool Sharpness | Use sharp, high-positive rake tools or diamond cutters | Minimizes friction and heat generation at the source |

| Cutting Parameters | Reduce speeds and feeds significantly | Lowers frictional heat and prevents material smearing |

| Active Cooling | Apply coolant (water-soluble) or compressed air | Removes heat before it deforms the material |

| Workholding | Secure without overtightening to avoid deformation | Maintains dimensional accuracy during machining |

Struggling with Teflon warping or poor finishes? KINTEK specializes in precision PTFE machining for the semiconductor, medical, and laboratory industries. Our expertise in heat management ensures your components meet exact tolerances without compromising safety or surface quality. We offer custom fabrication from prototypes to high-volume orders. Contact us today to discuss your project and achieve superior results with your Teflon parts!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE's low friction coefficient benefit impeller performance? Boost Efficiency & Lifespan

- In what industries are PTFE balls commonly used for chemical applications? Ensure Purity and Chemical Resistance

- What are the basic steps in PTFE compression molding? A Guide to the Press-and-Bake Process

- What are the advantages of using EPDM in wafer style and lugged butterfly valves? Superior Sealing for Water & Steam

- How is the body of a Teflon lip seal typically secured? Achieve Superior Sealing with Mechanical Clamping

- What are the advantages of using PTFE lip seals over traditional radial shaft seals? Maximize Performance in Harsh Conditions

- How do you use a Teflon sheet for heat press applications? Protect Your Projects and Equipment

- What is PTFE and how does it compare to elastomer rotary seals? Unlock Superior Sealing Performance