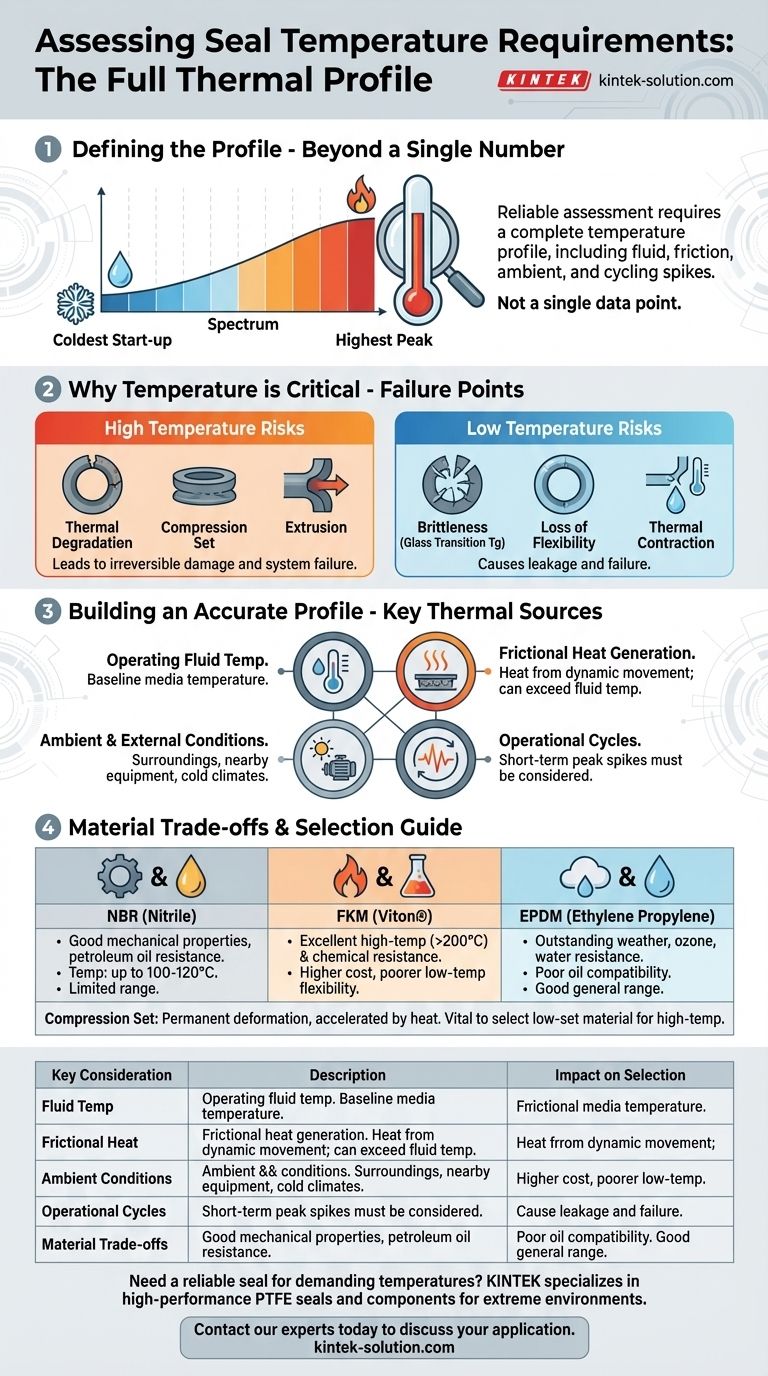

To properly assess temperature requirements, you must define the full thermal range of your application—from the coldest possible start-up to the highest peak operating temperature—and select a seal material engineered to remain stable and effective across that entire spectrum. This involves looking beyond just the fluid temperature to account for frictional heat, ambient conditions, and operational cycling.

The core mistake is viewing temperature as a single number. A truly reliable assessment requires creating a complete "temperature profile" for the seal's environment, as unexpected temperature spikes or cold-soak conditions are the primary drivers of premature failure.

Why Temperature is a Critical Failure Point

A seal's material properties are fundamentally linked to temperature. Exceeding its designed thermal range, even for short periods, can cause irreversible damage and lead to system failure.

The Impact of High Temperatures

High temperatures attack a seal's polymer structure. This leads to a loss of sealing force through thermal degradation and compression set.

The material can also soften excessively, increasing the risk of it being physically pushed into the clearance gap between components, a failure known as extrusion.

The Danger of Low Temperatures

As temperatures drop, elastomer seals lose their flexibility and become harder. If the temperature falls below the material's glass transition temperature (Tg), it will become brittle and glass-like.

In this state, the seal cannot respond to pressure or dynamic motion, leading to leakage. Thermal contraction can also cause the seal to shrink, opening up a leak path.

Building an Accurate Temperature Profile

A reliable temperature assessment goes beyond a single data point. You must consider every source of thermal energy that can affect the seal.

Operating Fluid Temperature

This is your baseline. The temperature of the hydraulic fluid, lubricant, or other media is the primary thermal load on the seal.

Frictional Heat Generation

In dynamic applications, the friction between the seal and a moving surface generates significant heat. This effect is magnified by high speeds, high pressures, and poor lubrication.

This friction can easily raise the seal's actual temperature well above the system's fluid temperature.

Ambient and External Conditions

Never overlook the surrounding environment. Consider heat from nearby motors, exhaust systems, or even direct sunlight.

Likewise, factor in cold ambient temperatures for equipment that sits idle overnight in cold climates, which dictates the seal's cold start-up performance.

Operational Cycles

Consider the full operational cycle. A system might run at a stable 80°C but experience short-term spikes to 120°C during peak load. The seal material must be rated for the peak, not the average.

Understanding Material Trade-offs

No single seal material is perfect for all conditions. Selecting the right one involves balancing performance characteristics and cost. The most critical trade-off is often temperature range versus fluid compatibility and price.

NBR (Nitrile)

NBR is a workhorse material with good mechanical properties and resistance to petroleum-based oils. However, its temperature range is limited, typically topping out around 100°C to 120°C (212°F to 250°F).

FKM (Viton®)

FKM is known for its excellent high-temperature and chemical resistance, often rated for continuous service above 200°C (400°F). The trade-off is a higher cost and generally poorer low-temperature flexibility compared to other materials.

EPDM (Ethylene Propylene)

EPDM offers outstanding resistance to weather, ozone, and water-based fluids but has very poor compatibility with petroleum oils. It has a good general-purpose temperature range.

The Problem of Compression Set

Compression set is the permanent deformation of a seal after being held in a compressed state. High temperatures drastically accelerate this process, causing the seal to lose its "memory" and ability to push back, which is essential for maintaining a seal. A material with low compression set is vital for high-temperature applications.

Making the Right Choice for Your Application

Use your temperature profile to guide your material selection. Focus on the specific demands of your system to find the optimal balance of performance and value.

- If your application experiences wide temperature swings: Select a material with a broad service range, like FKM, but always verify its specific low-temperature rating meets your cold-start requirements.

- If your primary challenge is high frictional heat: Choose a material with a maximum temperature rating significantly higher than the system's fluid temperature to account for this added thermal load.

- If your system faces extreme cold starts or is outdoors: Prioritize materials with a low glass transition temperature and excellent flexibility, such as specific grades of silicone or low-temp NBR.

- If reliability is paramount and cost is secondary: Investigate premium materials like perfluoroelastomers (FFKM), which offer the widest temperature ranges and best chemical resistance.

Ultimately, a rigorous and holistic temperature analysis is the foundation of reliable seal performance and system longevity.

Summary Table:

| Key Consideration | Description | Impact on Seal Selection |

|---|---|---|

| Operating Fluid Temperature | Baseline temperature of the system media. | Primary factor for material selection. |

| Frictional Heat Generation | Heat from seal movement against a surface. | Requires a material rated higher than fluid temperature. |

| Ambient/External Conditions | Heat from environment (e.g., motors, sunlight) or cold climates. | Dictates cold start performance and peak temperature tolerance. |

| Operational Cycles | Short-term temperature spikes during peak load. | Material must be rated for the peak temperature, not the average. |

| Material Trade-offs | Balancing temperature range, fluid compatibility, and cost. | E.g., FKM for high heat, EPDM for water/weather, NBR for cost-effective oil resistance. |

Need a reliable seal for demanding temperatures? KINTEK specializes in manufacturing high-performance PTFE seals and components that excel in extreme thermal environments. Our expertise in custom fabrication ensures your seals are precisely engineered for your application's unique temperature profile, from prototypes to high-volume orders.

Contact our experts today to discuss how we can enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What advantages do PTFE washers offer? Superior Chemical, Thermal, and Low-Friction Performance

- How should one choose between Teflon Bellow Mechanical Seals and traditional sealing solutions? A Guide for Corrosive & High-Purity Applications

- What are the main properties of PTFE sheets? Unlock Extreme Performance for Your Applications

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- What temperature range can PTFE seals typically operate in? From Cryogenic -200°C to High-Temp 260°C

- What is the purpose of using Teflon sheets with a heat press machine? Protect Your Press & Improve Print Quality

- How are control valves customized for different processes? Tailor Performance for Your Application

- Why are gaskets made of Teflon used in construction? Prevent Galvanic Corrosion Between Dissimilar Metals