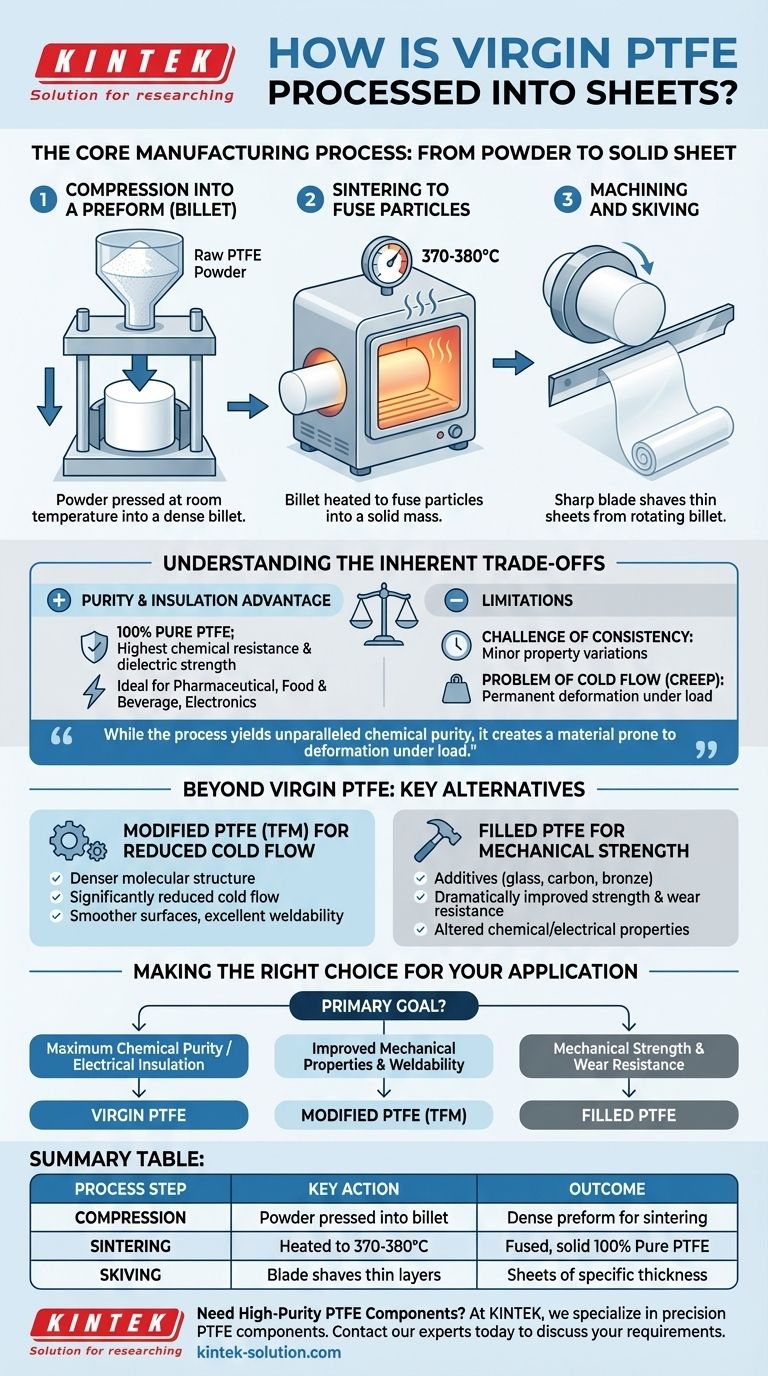

The production of virgin PTFE sheets is a multi-stage process that transforms raw resin powder into a solid, usable form. The material is first compressed into a dense block called a billet at room temperature. This billet is then sintered in an oven at approximately 370-380°C, fusing the particles together. After cooling, this solid block is machined, most commonly through a process called skiving, to create sheets of a specific thickness.

While the compression and sintering process yields sheets of unparalleled chemical purity, it also creates a material prone to deformation under load (cold flow). Understanding this inherent trade-off is the key to selecting the right type of PTFE for your specific application.

The Core Manufacturing Process: From Powder to Solid Sheet

The journey from raw PTFE resin to a finished sheet involves three distinct physical transformations. Unlike many plastics, PTFE is not melt-processed, which gives it unique properties and processing challenges.

Step 1: Compression into a Preform (Billet)

Raw virgin PTFE powder is loaded into a mold and subjected to high pressure at room temperature. This compacts the powder into a dense, solid cylinder or block known as a preform or billet. The initial quality of this billet is critical for the final sheet's properties.

Step 2: Sintering to Fuse Particles

The billet is carefully removed from the mold and placed into a specialized oven. It is heated in a highly controlled cycle to a temperature just below its melting point (around 370-380°C). This process, sintering, causes the individual PTFE particles to fuse together, creating a solid, stable mass.

Step 3: Machining and Skiving

Once the billet has been sintered and properly cooled, it is ready for final processing. To create sheets, a method called skiving is typically used, where a long, sharp blade shaves a continuous, thin layer from the billet as it is rotated, similar to peeling a potato.

Understanding the Inherent Trade-offs

The standard manufacturing process for virgin PTFE creates a material with exceptional purity but also distinct limitations that are critical to understand.

The Challenge of Consistency

Achieving perfectly uniform physical properties throughout a large billet is difficult. This can lead to minor variations in density and other characteristics depending on where the sheet was cut from the block, a factor to consider in highly sensitive applications.

The Problem of Cold Flow (Creep)

Virgin PTFE is a relatively soft material subject to creep, also known as cold flow. When a load is applied, the material will slowly and permanently deform over time. This makes it unsuitable for high-load structural applications without reinforcement.

The Purity and Insulation Advantage

The primary benefit of this process is that it produces 100% pure PTFE. This results in a material with the highest possible chemical resistance and dielectric strength, making it the default choice for the pharmaceutical, food and beverage, and sensitive electronics industries.

Beyond Virgin PTFE: Exploring Key Alternatives

When the properties of virgin PTFE do not meet an application's demands, modified and filled grades provide enhanced performance. These materials are processed in a similar manner but start with a different base resin.

Modified PTFE (TFM) for Reduced Cold Flow

Modified PTFE, or TFM, includes a chemical modifier that creates a denser molecular structure. This results in a material with significantly reduced cold flow (by a factor of three), smoother machined surfaces, and excellent weldability, offering a middle ground between virgin and filled grades.

Filled PTFE for Mechanical Strength

For industrial applications requiring high mechanical strength and wear resistance, filled PTFE is used. Additives like glass, carbon, or bronze are blended with the PTFE resin before compression. These fillers dramatically improve strength and reduce creep, but they also alter the material's chemical resistance and electrical properties.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary goal.

- If your primary focus is maximum chemical purity or electrical insulation: Virgin PTFE is the correct choice, especially for pharmaceutical, food and beverage, or sensitive electronics.

- If your primary focus is mechanical strength and wear resistance: Choose a Filled PTFE, such as one with a glass or carbon filler, for demanding industrial components.

- If your primary focus is improved mechanical properties with weldability: Modified PTFE (TFM) offers a superior balance, reducing cold flow while maintaining excellent chemical resistance.

By understanding how PTFE is made, you can better predict its performance and choose the precise material your project demands.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| Compression | PTFE powder is pressed into a billet at room temperature. | Creates a dense preform for sintering. |

| Sintering | Billet is heated to 370-380°C to fuse particles. | Forms a solid, stable mass of 100% pure PTFE. |

| Skiving | A sharp blade shaves thin layers from the cooled billet. | Produces sheets of a specific, consistent thickness. |

Need High-Purity PTFE Components for Your Application?

Understanding the nuances of PTFE processing is key to selecting the right material. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and specialized industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact performance your project demands.

Contact our experts today to discuss your specific requirements and leverage our expertise for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions