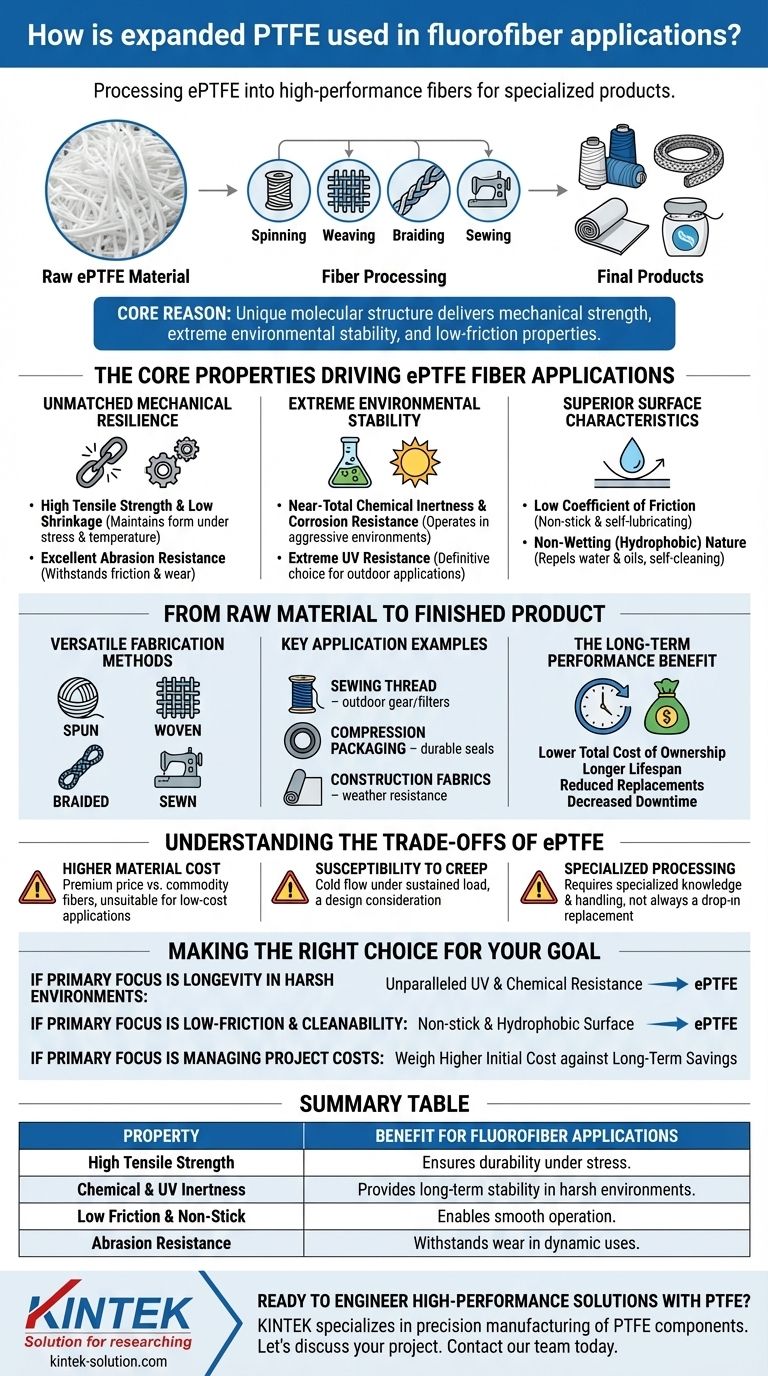

In fluorofiber applications, expanded PTFE (ePTFE) is used by processing it into high-performance fibers that are then woven, spun, braided, or sewn into specialized final products. These products leverage the material's inherent strength, chemical inertness, and environmental resistance for demanding roles such as industrial sewing threads, compression packaging, architectural fabrics, and medical-grade dental floss.

The core reason for using expanded PTFE in fibers is its unique molecular structure, which delivers an exceptional combination of mechanical strength, extreme environmental stability, and low-friction surface properties that few other polymers can match in a single package.

The Core Properties Driving ePTFE Fiber Applications

Expanded PTFE is not chosen by accident. Its selection for high-stakes applications is a direct result of several key material characteristics that work in concert.

Unmatched Mechanical Resilience

ePTFE fibers exhibit high tensile strength and low shrinkage, ensuring they maintain their form and function under significant stress and temperature changes.

This is coupled with excellent abrasion resistance, allowing the fibers to withstand friction and wear in dynamic applications like industrial braids and seals.

Extreme Environmental Stability

One of the most significant advantages of ePTFE is its near-total chemical inertness and resistance to corrosion. It can operate in aggressive chemical environments without degrading.

Furthermore, its extreme UV resistance makes it the definitive choice for outdoor applications, such as architectural fabrics, where constant sun exposure would rapidly destroy lesser materials.

Superior Surface Characteristics

The material possesses an incredibly low coefficient of friction, making it inherently non-stick and self-lubricating. This is critical for applications like dental floss or low-drag cable fillers.

Its non-wetting (hydrophobic) nature means it repels water and oils, which promotes a self-cleaning effect in certain environments and prevents moisture absorption that could compromise performance.

From Raw Material to Finished Product

The versatility of ePTFE is not just in its properties but also in how it can be converted into a wide range of textile forms.

Versatile Fabrication Methods

The base ePTFE material can be processed using standard textile techniques. It can be spun into yarn, woven into fabrics, braided into ropes and seals, or sewn directly into assemblies.

Key Application Examples

This adaptability leads to its use in highly specialized products. As a sewing thread, its UV and chemical resistance ensure seams never fail in outdoor gear or chemical filter bags. In compression packaging, its strength and low friction create a durable, reliable seal. For construction fabrics, its weather resistance provides a decades-long lifespan.

The Long-Term Performance Benefit

While ePTFE components may have a higher initial cost, they deliver a lower total cost of ownership. The material's durability leads to a longer lifespan, reduced need for replacements, and decreased industrial downtime for maintenance.

Understanding the Trade-offs of ePTFE

No material is perfect for every situation. Being a trusted advisor means acknowledging the practical limitations and considerations of working with expanded PTFE.

Higher Material Cost

ePTFE is a premium, high-performance polymer. Its initial procurement cost is significantly higher than that of commodity fibers like polyester or nylon. This makes it unsuitable for cost-sensitive, disposable, or low-performance applications.

Susceptibility to Creep

Like all fluoropolymers, PTFE can be susceptible to "creep" or cold flow—a tendency to deform slowly under a sustained load. While the expansion and fiber-drawing process improves this characteristic, it remains a design consideration for high-load static applications.

Specialized Processing

While ePTFE can be processed with textile equipment, its unique properties often require specialized knowledge and handling techniques to optimize the final product's performance. It is not always a direct drop-in replacement for conventional fibers.

Making the Right Choice for Your Goal

Selecting ePTFE fluorofiber should be a deliberate decision based on clear performance requirements.

- If your primary focus is longevity in harsh chemical or outdoor environments: The unparalleled UV and chemical resistance of ePTFE makes it the most reliable choice.

- If your primary focus is low-friction and cleanability: The non-stick and hydrophobic surface properties of ePTFE are its key differentiators.

- If your primary focus is managing project costs: You must carefully weigh the higher initial cost of ePTFE against the significant long-term savings from reduced maintenance and replacement cycles.

Ultimately, expanded PTFE fibers provide an engineered solution for applications where performance and reliability cannot be compromised.

Summary Table:

| Property | Benefit for Fluorofiber Applications |

|---|---|

| High Tensile Strength | Ensures durability and reliability under stress in seals, braids, and threads. |

| Chemical & UV Inertness | Provides long-term stability and performance in harsh outdoor or chemical environments. |

| Low Friction & Non-Stick | Enables smooth operation in applications like dental floss and low-drag components. |

| Abrasion Resistance | Withstands wear in dynamic uses such as industrial sewing and compression packaging. |

Ready to Engineer High-Performance Solutions with PTFE?

When your application demands the unique combination of strength, chemical inertness, and environmental stability that only expanded PTFE can provide, partnering with an expert manufacturer is crucial.

KINTEK specializes in the precision manufacturing and custom fabrication of PTFE components—including specialized seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We help you navigate material selection and optimize designs, from initial prototypes to high-volume production runs, ensuring you get a component that delivers long-term value and performance.

Let's discuss how we can bring the benefits of PTFE to your next project.

Contact our team today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support