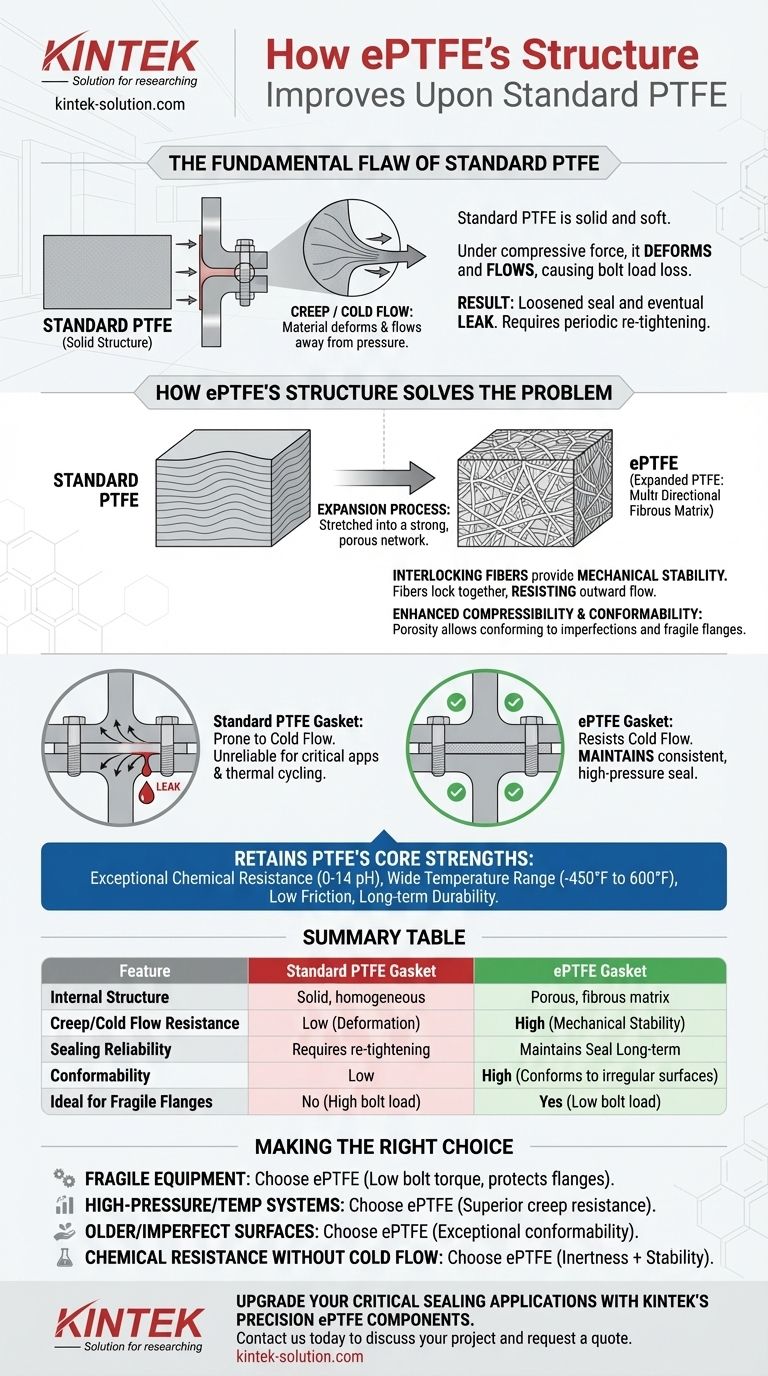

The key structural difference is that ePTFE (expanded Polytetrafluoroethylene) is not a solid material but a multi-directional fibrous matrix. This structure is created by expanding standard PTFE, which transforms the material into an incredibly strong, porous network of fibers and nodes. This fibrous structure directly solves the primary weaknesses of standard PTFE gaskets, namely their tendency to deform under pressure, a problem known as creep or cold flow.

While standard PTFE offers unmatched chemical resistance, its solid structure is prone to "cold flow," causing the seal to loosen over time. The engineered, multi-fiber structure of ePTFE creates a gasket that is both chemically inert and mechanically stable, providing a durable and reliable seal where standard PTFE would fail.

The Fundamental Flaw of Standard PTFE Gaskets

Understanding Creep and Cold Flow

Standard PTFE is a relatively soft, solid material. When subjected to the compressive force of a bolted flange, it has a tendency to slowly deform and flow away from the point of highest pressure.

This phenomenon, known as creep or cold flow, causes the bolt load to decrease over time. The gasket effectively thins out, leading to a loss of sealing pressure and an eventual leak.

The Impact on Sealing Reliability

Because of cold flow, standard PTFE gaskets often require periodic re-tightening of bolts to maintain a proper seal. This makes them unreliable for critical applications or in systems with thermal cycling, where temperature changes can accelerate this process.

How ePTFE's Structure Solves the Problem

The Expansion Process: Creating a Fibrous Matrix

ePTFE is manufactured by rapidly stretching PTFE under specific conditions. This process radically alters its internal structure, pulling the material apart into a microscopic web of strong, interconnected fibers.

This multi-directional fibrous network gives the material incredible tensile strength and structural integrity, unlike the solid, malleable form of standard PTFE.

Resisting Creep and Cold Flow

The interlocking fibers in ePTFE provide robust mechanical stability. When compressed, the fibers lock together and resist the urge to flow outwards.

This structural reinforcement fundamentally solves the cold flow problem, allowing an ePTFE gasket to maintain a consistent, high-pressure seal without needing to be re-torqued.

Enhancing Compressibility and Conformability

The expansion process also introduces porosity, making ePTFE gaskets highly compressible and soft. They can easily conform to surface imperfections, scratches, or irregularities on a flange face.

This allows them to create an effective seal on surfaces where a rigid, solid gasket would fail, even under lower bolt loads.

Retaining PTFE's Core Strengths

Critically, the expansion process does not compromise the inherent benefits of PTFE. ePTFE retains its exceptional chemical resistance across the entire 0-14 pH range.

It also keeps its extremely wide operational temperature range (up to 600°F / 315°C), low coefficient of friction, and long-term durability without aging or becoming brittle.

The Practical Advantages of the ePTFE Structure

Superior Seal on Fragile or Irregular Surfaces

The high compressibility of ePTFE makes it the ideal choice for fragile equipment, such as glass-lined, ceramic, or plastic flanges. It can create a tight seal with minimal bolt force, preventing damage to the flange.

Its ability to conform to rough surfaces also makes it perfect for older, worn, or warped equipment.

Reliability in High-Stress Applications

Thanks to its creep resistance, ePTFE excels in demanding conditions. It can maintain seal integrity in systems with high pressures (up to 3000+ psi) and significant temperature fluctuations.

This reliability eliminates the maintenance burden associated with standard PTFE and reduces the risk of unexpected leaks in critical processes.

Making the Right Choice for Your Application

An ePTFE gasket is not simply an alternative to standard PTFE; it is a direct solution to its primary sealing failures.

- If your primary focus is sealing fragile equipment: Choose ePTFE for its ability to create a secure seal with very low bolt torque, protecting your flanges from damage.

- If your primary focus is reliability in high-pressure or high-temperature systems: Choose ePTFE for its superior creep resistance, which ensures a stable and long-lasting seal.

- If your primary focus is sealing older or imperfect flange surfaces: Choose ePTFE for its exceptional conformability, which fills in scratches and irregularities to prevent leaks.

- If you need broad chemical resistance without the risk of cold flow: Choose ePTFE to get the chemical inertness of standard PTFE with vastly improved mechanical stability.

Ultimately, the unique fibrous structure of ePTFE provides the mechanical integrity needed to turn an excellent chemical-resistant material into a superior and reliable sealing solution.

Summary Table:

| Feature | Standard PTFE Gasket | ePTFE Gasket |

|---|---|---|

| Internal Structure | Solid, homogeneous material | Porous, multi-directional fibrous matrix |

| Creep/Cold Flow Resistance | Low (prone to deformation) | High (excellent mechanical stability) |

| Sealing Reliability | Requires re-tightening; can leak over time | Maintains seal integrity long-term |

| Conformability | Low | High (conforms to irregular surfaces) |

| Ideal for Fragile Flanges | No (requires high bolt load) | Yes (seals effectively with low bolt load) |

Upgrade your critical sealing applications with KINTEK's precision ePTFE components.

Our custom-fabricated ePTFE gaskets are engineered to solve the cold flow problems of standard PTFE, delivering unmatched reliability for the semiconductor, medical, laboratory, and industrial sectors. We combine the full chemical resistance of PTFE with superior mechanical strength to ensure a durable, long-lasting seal under high pressure and temperature cycling.

Whether you need prototypes or high-volume orders, KINTEK prioritizes precision production to meet your exact specifications.

Contact us today to discuss your project and request a quote.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- How does PTFE perform in chemically corrosive environments? Unmatched Chemical Immunity & Reliability

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance