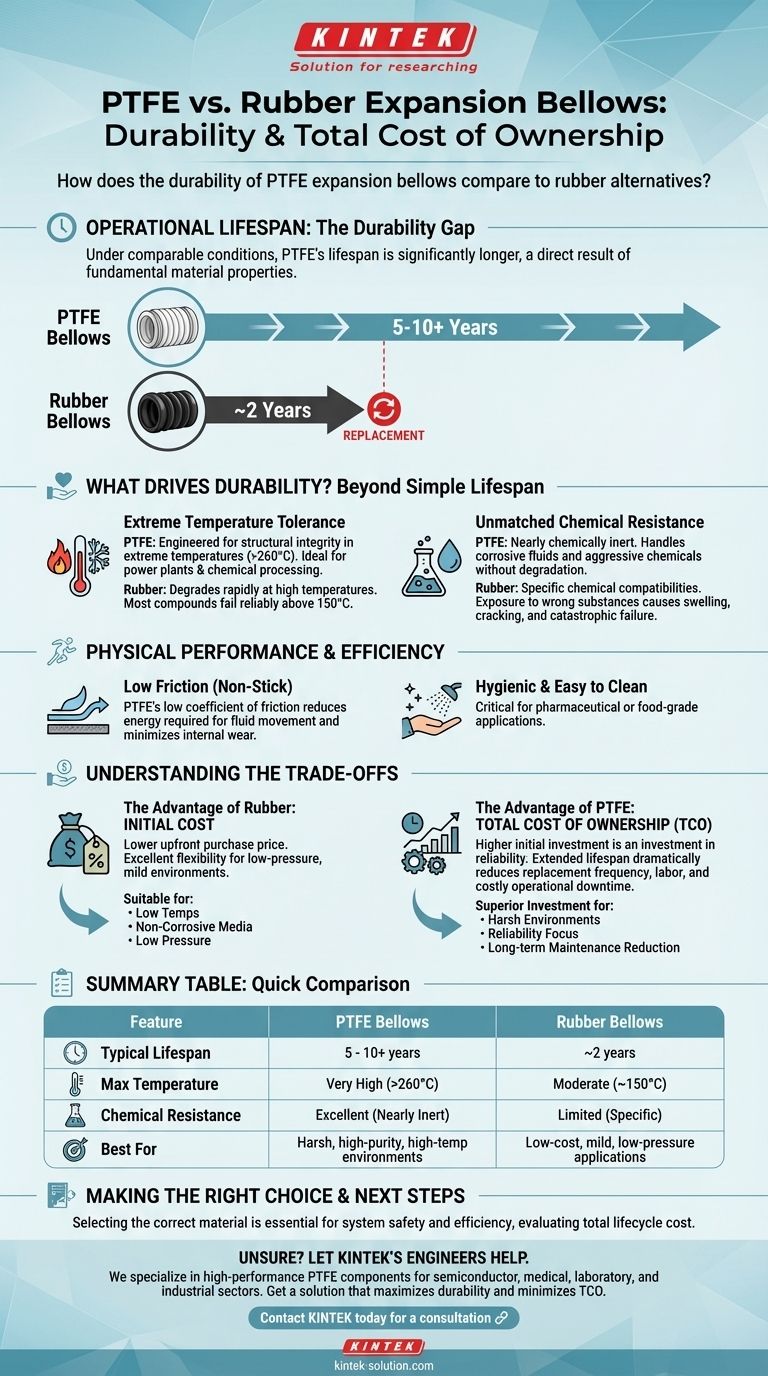

In terms of operational lifespan, PTFE expansion bellows are significantly more durable than their rubber alternatives. Under comparable conditions, a PTFE bellow can be expected to last 5 to 10 years or more, whereas a rubber bellow may require replacement in as little as 2 years. This difference in longevity is a direct result of the fundamental material properties of each.

The decision between PTFE and rubber bellows is not just about initial durability, but about matching the material's inherent resistance to the specific thermal and chemical stresses of your operational environment. The higher initial cost of PTFE is often justified by its superior performance and dramatically lower total cost of ownership in demanding applications.

What Drives Durability? Beyond Simple Lifespan

An expansion bellow's durability is a function of how well its material withstands the operational environment. The significant lifespan advantage of PTFE is rooted in its superior resistance to the primary causes of material failure: heat and chemical attack.

Extreme Temperature Tolerance

PTFE is engineered to maintain its structural integrity in extreme temperature conditions, such as those found in power plants or chemical processing facilities.

Rubber, by contrast, degrades rapidly at high temperatures. Most rubber compounds cannot reliably operate above 150°C, leading to premature failure in high-heat systems where PTFE excels.

Unmatched Chemical Resistance

A key advantage of PTFE is that it is nearly chemically inert. It can handle a vast range of corrosive fluids and aggressive chemicals without degrading, ensuring a long and reliable service life.

Rubber bellows, on the other hand, have very specific chemical compatibilities. Exposure to the wrong substance can cause the material to swell, crack, or dissolve, leading to catastrophic failure.

Physical Performance and Efficiency

PTFE possesses an extremely low coefficient of friction. This "non-stick" property reduces the energy required to move fluids through the system and minimizes internal wear over time.

This characteristic also makes PTFE bellows highly hygienic and easy to clean, a critical factor in pharmaceutical or food-grade applications.

Understanding the Trade-offs

While PTFE offers superior durability in harsh conditions, rubber remains a viable choice for specific, less-demanding scenarios. The decision hinges on balancing initial cost against long-term reliability and maintenance.

The Advantage of Rubber: Initial Cost

The primary advantage of rubber bellows is their lower upfront purchase price. They also provide excellent flexibility for absorbing movement and vibration, particularly in low-pressure systems.

If the application involves moderate temperatures, non-corrosive media, and low pressure, a rubber bellow can be a cost-effective initial solution.

The Advantage of PTFE: Total Cost of Ownership

The higher initial cost of a PTFE bellow is an investment in reliability. Its extended lifespan of 5-10+ years dramatically reduces replacement frequency.

This leads to a lower total cost of ownership (TCO) by minimizing expenditures on parts, labor, and, most importantly, costly operational downtime.

Making the Right Choice for Your Application

Selecting the correct material is essential for ensuring system safety and efficiency. Your choice should be guided by the specific demands of the operating environment.

- If your primary focus is minimizing upfront cost in a mild environment: Rubber bellows are a suitable choice for applications with low temperatures, low pressures, and non-corrosive media.

- If your primary focus is reliability in a harsh chemical or high-temperature environment: PTFE is the only reliable choice, as its material properties are engineered to withstand these stresses.

- If your primary focus is reducing long-term maintenance and operational downtime: PTFE's exceptional durability makes it the superior investment, ensuring system integrity for years.

Ultimately, choosing the right expansion bellow requires evaluating the total lifecycle cost, not just the initial purchase price.

Summary Table:

| Feature | PTFE Bellows | Rubber Bellows |

|---|---|---|

| Typical Lifespan | 5 - 10+ years | ~2 years |

| Max Temperature | Very High (>260°C) | Moderate (~150°C) |

| Chemical Resistance | Excellent (Nearly Inert) | Limited (Specific) |

| Best For | Harsh, high-purity, high-temp environments | Low-cost, mild, low-pressure applications |

Unsure which bellow material is right for your system's demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that maximizes durability and minimizes total cost of ownership.

Let our engineers help you select the optimal bellow for your specific thermal, chemical, and pressure requirements.

Contact KINTEK today for a consultation to discuss your application and receive a quote for custom-fabricated PTFE bellows, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What support is available for selecting the right PTFE valve design and size? Get Expert Guidance for Your Application

- What makes Teflon sheets resistant to chemicals? The Power of a Molecular Fortress

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What are the key benefits of using PTFE bellows? Achieve Superior Chemical Resistance and Purity

- How do PTFE bellow seals perform with chemical reagents? Superior Resistance to Corrosive Chemicals

- Why is chemical resistance important for PTFE gaskets and sheets? Ensure Unmatched Safety and Reliability

- How does the heat resistance of Teflon sheets benefit industrial applications? Unlock Performance Under Thermal Stress