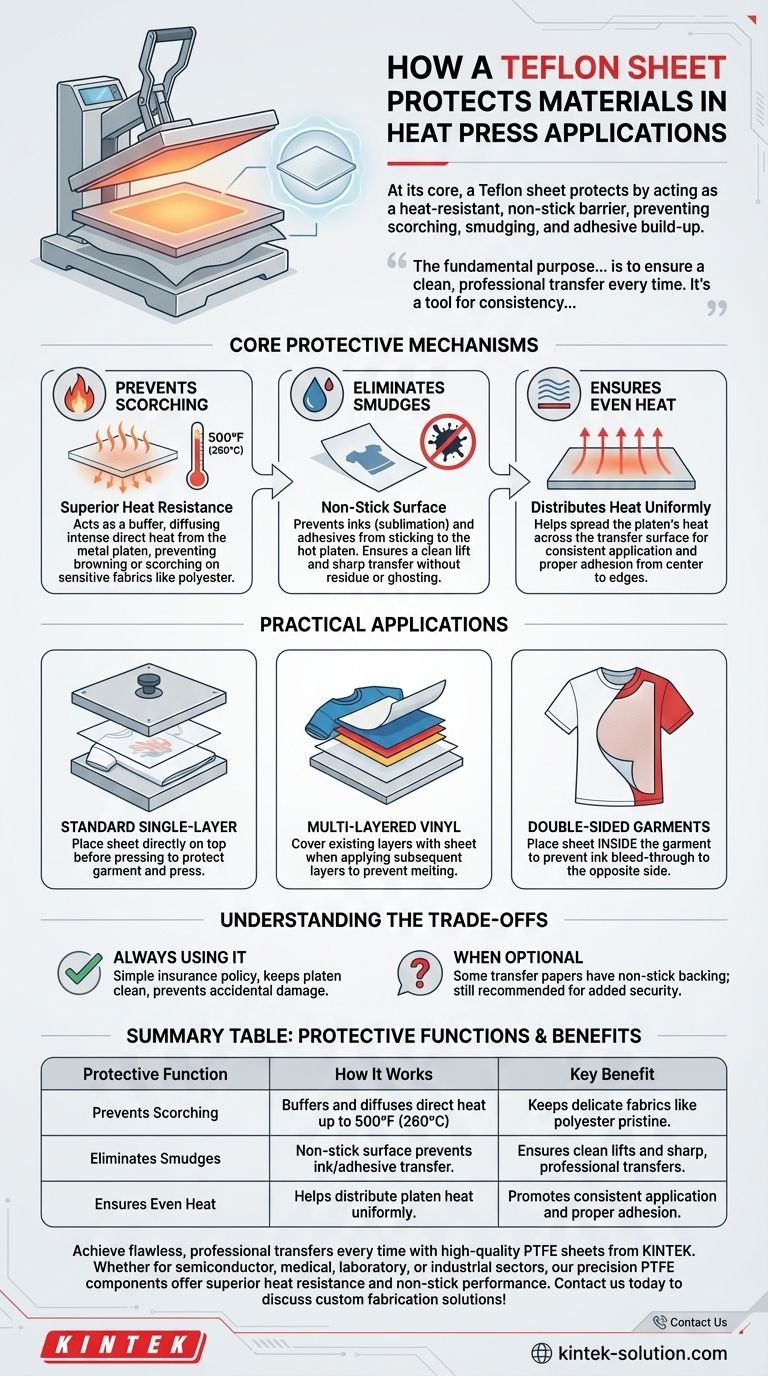

At its core, a Teflon sheet protects materials by acting as a heat-resistant, non-stick barrier between the hot upper platen of your press and your project. This simple layer prevents three common heat press failures: scorching the fabric, smudging the ink or vinyl, and allowing adhesive to build up on your equipment.

The fundamental purpose of a Teflon sheet is to ensure a clean, professional transfer every time. It isn't just a protective accessory; it's a tool for consistency that isolates your project from the direct, raw heat of the press.

The Core Protective Mechanisms of a Teflon Sheet

To understand its value, we need to look at the specific properties of Teflon (PTFE) and how they translate directly to better heat press results.

Preventing Scorching with Superior Heat Resistance

A Teflon sheet can withstand temperatures up to 500°F (260°C) without degrading. It acts as a buffer, diffusing the intense, direct heat from the metal platen.

This diffusion prevents the "browning" or scorching that can occur on sensitive fabrics like polyester or light-colored cottons, ensuring the material around your design remains pristine.

Eliminating Smudges with a Non-Stick Surface

The most famous property of Teflon is its non-stick surface. During a transfer, inks can sublimate and adhesives can melt. Without a barrier, these substances can stick to the hot platen.

When the platen lifts, this residue can either pull up part of your design or get re-deposited on a later project, causing smudges and ghosting. The Teflon sheet ensures nothing sticks, leading to a clean lift and a sharp transfer.

Ensuring Even Heat Distribution

While the primary function is protection, the sheet also helps distribute the platen's heat more evenly across the surface of your transfer.

This subtle benefit promotes a more consistent application, ensuring that all parts of the design—from the center to the edges—receive the uniform heat and pressure needed for proper adhesion.

Practical Applications: When and How to Use It

Using the sheet correctly is straightforward but critical for protecting different types of projects.

For Standard Single-Layer Transfers

This is the most common use. Simply place your garment and transfer material on the lower platen and lay the Teflon sheet directly on top before closing the press. It protects both the garment and the press itself.

For Multi-Layered Vinyl Projects

When pressing multiple layers of heat transfer vinyl (HTV), you must protect the layers you've already applied. Covering the existing vinyl with a Teflon sheet prevents it from melting or getting a direct impression from the hot platen as you apply subsequent layers.

For Double-Sided Garments

If you are printing on both sides of a shirt, it is crucial to place a Teflon sheet inside the garment. This prevents the ink or vinyl from the first side from being reactivated by the heat and bleeding through to the opposite side.

Understanding the Trade-offs: Is It Always Necessary?

While it is a best practice, the necessity can be debated.

The Case for Always Using It

Using a Teflon sheet for every press is a simple, low-cost insurance policy. It guarantees your platen stays clean, which prevents accidental damage to future projects. It takes only a second and eliminates the risk of a costly mistake.

When It Might Be Optional

Some transfer papers come with their own non-stick backing sheet that serves a similar purpose. In these cases, an additional Teflon sheet may not be strictly required. However, many professionals still use one for added security and to standardize their workflow.

Making the Right Choice for Your Project

Your goal determines how essential the Teflon sheet is.

- If your primary focus is protecting delicate fabrics: Use the sheet to act as a buffer against scorching and yellowing from direct, high heat.

- If your primary focus is creating multi-color or layered designs: Use the sheet over each applied layer to shield it from the platen while you press the next one.

- If your primary focus is maintaining your equipment: Use the sheet every time to prevent adhesive and ink residue from building up on your heat platen, ensuring its longevity.

Ultimately, incorporating a Teflon sheet into your workflow is one of the easiest steps you can take to achieve consistent, professional-grade results.

Summary Table:

| Protective Function | How It Works | Key Benefit |

|---|---|---|

| Prevents Scorching | Buffers and diffuses direct heat up to 500°F (260°C) | Keeps delicate fabrics like polyester pristine |

| Eliminates Smudges | Non-stick surface prevents ink/adhesive transfer | Ensures clean lifts and sharp, professional transfers |

| Ensures Even Heat | Helps distribute platen heat uniformly across the project | Promotes consistent application and proper adhesion |

Achieve flawless, professional transfers every time with high-quality PTFE sheets from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-manufactured PTFE components (like seals, liners, and labware) are engineered for superior heat resistance and non-stick performance. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring you get the exact solution for your heat press or specialized application needs.

Contact us today to discuss your requirements and discover how KINTEK's precision PTFE components can protect your materials and enhance your results!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries