At their core, Teflon-coated pins function as positioning components with a built-in, high-performance protective layer. While the pin itself holds a machine part in place, the Teflon coating creates an exceptionally low-friction, non-stick surface. This coating drastically reduces wear, prevents parts from seizing, and often eliminates the need for liquid lubricants.

The key function of a Teflon coating is to transform a simple mechanical pin from a static fastener into an active surface-engineered component. It solves the problem of friction and wear at critical connection points, enhancing the machinery's overall efficiency and lifespan.

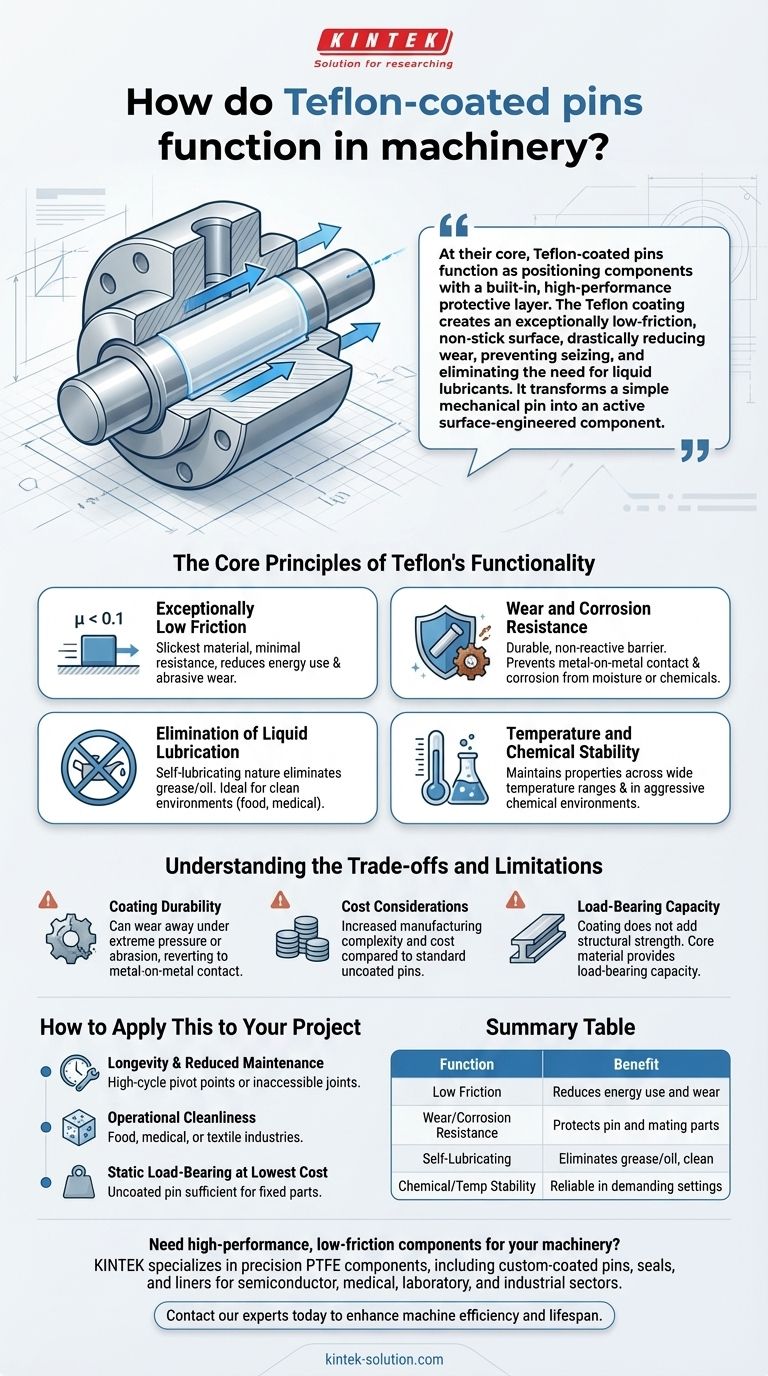

The Core Principles of Teflon's Functionality

To understand why these pins are used, we must look at the fundamental properties of the Polytetrafluoroethylene (PTFE) coating, commonly known as Teflon. This material provides several distinct advantages in a mechanical system.

Exceptionally Low Friction

The primary benefit of Teflon is its incredibly low coefficient of friction. It is one of the "slickest" materials known, meaning objects can slide against it with minimal resistance.

This property directly reduces the energy required for movement and minimizes the abrasive wear that occurs when two surfaces rub against each other. It prevents the stick-slip motion and overheating common in high-friction joints.

Wear and Corrosion Resistance

The Teflon coating acts as a durable, non-reactive barrier between the pin and the component it is securing.

This barrier physically prevents metal-on-metal contact, protecting both the pin and the surrounding machinery from wear and galling. As Teflon is chemically inert, it also protects the underlying metal from corrosion caused by moisture or chemicals.

Elimination of Liquid Lubrication

In many applications, Teflon's self-lubricating nature eliminates the need for grease or oil.

This is a significant advantage in environments where contamination is a concern, such as in food processing, textile manufacturing, or medical equipment. It also reduces maintenance by removing the need to re-apply lubricants.

Temperature and Chemical Stability

Teflon maintains its key properties across a wide range of operating temperatures and in the presence of aggressive chemicals.

This makes Teflon-coated pins reliable components for demanding industrial environments, from pump housings to high-temperature conveyor systems, where other materials might degrade or fail.

Understanding the Trade-offs and Limitations

While highly effective, Teflon-coated pins are not a universal solution. An objective analysis requires acknowledging their limitations.

Coating Durability

The Teflon coating itself can wear away over time, especially under extremely high pressure or in the presence of abrasive particulates.

Once the coating is compromised, the pin loses its low-friction benefits and reverts to being a simple metal-on-metal contact point, which can then accelerate wear.

Cost Considerations

Adding a high-performance coating to a pin increases its manufacturing complexity and cost compared to a standard, uncoated steel or brass pin.

The decision to use a coated pin must be justified by the need for reduced friction, wear protection, or cleanliness that offsets the higher initial price.

Load-Bearing Capacity

The Teflon coating is a surface treatment; it does not add to the structural or shear strength of the pin itself.

The pin's core material (typically steel) is what provides the mechanical strength to hold parts in position. The coating's role is purely to manage surface interaction.

How to Apply This to Your Project

Your choice should be dictated by the specific demands of the mechanical joint in question.

- If your primary focus is longevity and reduced maintenance: Use Teflon-coated pins in high-cycle pivot points or inaccessible joints where regular lubrication is impractical.

- If your primary focus is operational cleanliness: These pins are the ideal choice for applications in the food, medical, or textile industries where grease and oil are contaminants.

- If your primary focus is static load-bearing at the lowest cost: An uncoated pin is likely sufficient for an assembly where parts are fixed and there is no relative motion or wear concern.

Ultimately, a Teflon-coated pin elevates a basic fastener into a strategic component for improving long-term machine performance.

Summary Table:

| Function | Benefit |

|---|---|

| Low Friction | Reduces energy use and wear in moving parts |

| Wear/Corrosion Resistance | Protects pin and mating parts from damage |

| Self-Lubricating | Eliminates grease/oil, ideal for clean environments |

| Chemical/Temp Stability | Reliable performance in demanding industrial settings |

Need high-performance, low-friction components for your machinery?

KINTEK specializes in manufacturing precision PTFE (Teflon) components, including custom-coated pins, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors by combining precision production with custom fabrication—from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance your machine's efficiency and lifespan.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to the sealing performance of ball valves? Achieve Leak-Free, Durable Sealing

- What are the key properties of PTFE that make it suitable for structural bearings? Unlock Superior Load Support & Movement

- What are the key advantages of PTFE lined pipes? Superior Corrosion Resistance & Cost-Effective Flow

- What are the benefits of PTFE's low friction coefficient in shaft seals? Boost Efficiency & Extend Equipment Life

- Why is Teflon coating popular in the food processing industry? Boost Efficiency & Product Quality

- What are the advantages of using PTFE gaskets? Achieve Superior Chemical and Thermal Sealing

- Why is PTFE a preferred material for medical device seals? Ensuring Safety, Reliability, and Performance

- What are the key properties of PTFE balls? Unlock Superior Performance for Demanding Applications