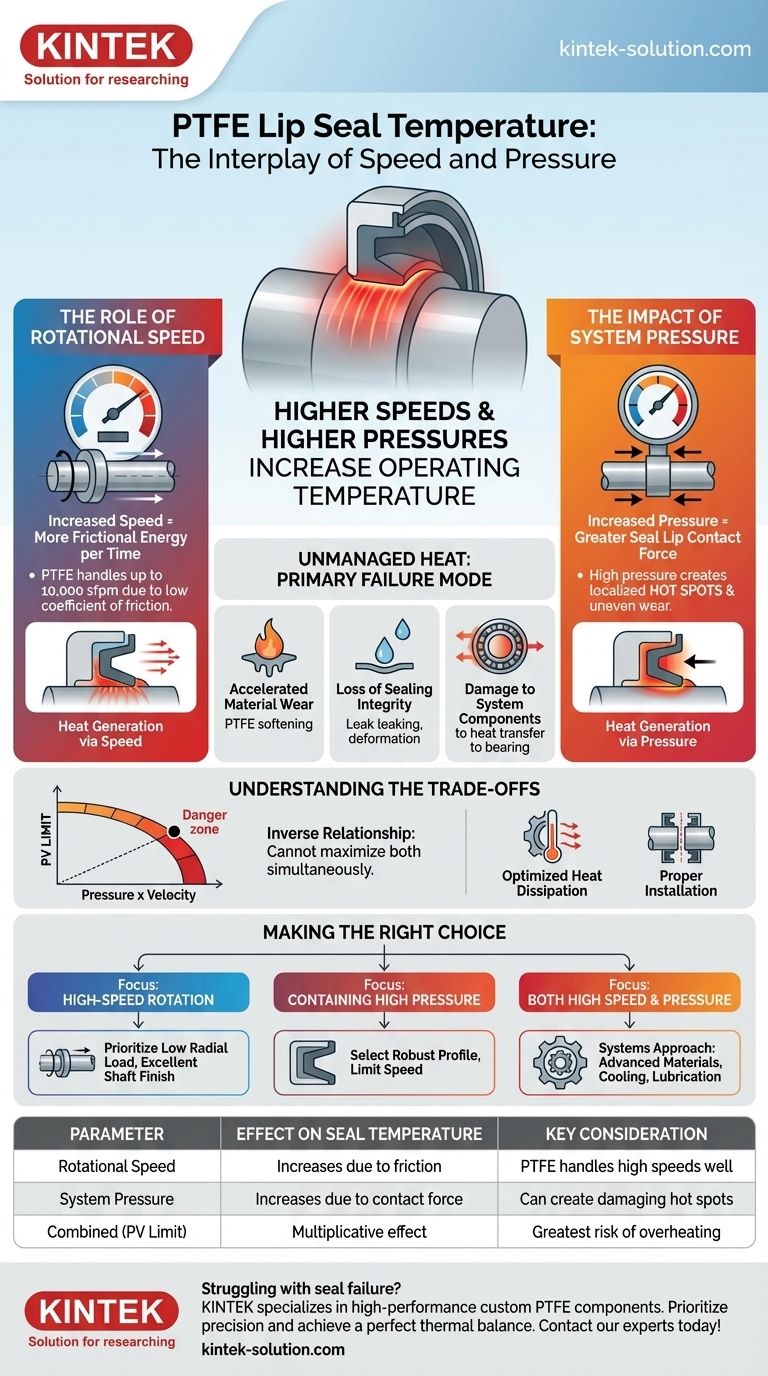

In short, both higher speeds and higher pressures increase the operating temperature of a PTFE lip seal. This temperature rise is a direct result of increased friction at the sealing interface. As rotational speed increases, the surface moves more rapidly against the seal lip, and as pressure increases, the seal lip is forced more firmly against the shaft, both of which generate significant frictional heat.

The central challenge in any dynamic sealing application is managing the frictional heat generated at the contact point. For PTFE lip seals, successfully balancing operational speed and pressure is the critical factor that dictates the seal's performance, integrity, and lifespan.

The Physics of Heat Generation in Seals

Understanding how operational parameters translate into heat is fundamental to preventing premature seal failure. The two primary drivers are rotational speed and system pressure.

The Role of Rotational Speed

Friction is the primary source of heat in a dynamic seal. As the rotational speed of the shaft increases, the amount of frictional energy generated per unit of time also increases, leading to a higher operating temperature.

PTFE is well-suited for high-speed applications, capable of handling surface speeds up to 10,000 feet per minute (sfpm). This is largely due to PTFE's inherently low coefficient of friction and the lower radial contact force typical of these seal designs.

The Impact of System Pressure

System pressure exerts force on the seal, pushing the lip more firmly against the rotating shaft. This increased contact force directly elevates friction and, consequently, the temperature.

In dynamic applications, this can be particularly problematic. Higher pressure can create localized hot spots on the seal lip, leading to uneven wear and potential material degradation in a concentrated area.

Why Unmanaged Heat is the Primary Failure Mode

Failing to account for the heat generated by speed and pressure can lead to rapid and catastrophic seal failure. The consequences are predictable and severe.

Accelerated Material Wear

Excessive heat can soften the PTFE compound and its fillers. This softening dramatically increases the rate of wear, shortening the effective service life of the seal.

Loss of Sealing Integrity

If the temperature exceeds the seal material's limits, it can cause permanent deformation or degradation. This compromises the seal's ability to maintain contact with the shaft, resulting in leaks.

Damage to System Components

The heat generated at the seal interface doesn't stay there. It can conduct through the shaft and housing, potentially affecting bearings, lubricants, and other nearby components.

Understanding the Trade-offs

You cannot simply maximize both speed and pressure without consequences. Designing a reliable system requires a clear understanding of the interplay between these factors.

Speed vs. Pressure: An Inverse Relationship

For any given seal design, there is a PV limit (Pressure x Velocity). Pushing both speed and pressure to their maximum specified limits simultaneously will almost certainly lead to rapid overheating and failure.

The Critical Role of Seal Design

Effective heat management is often engineered into the seal itself. Features that promote optimized heat dissipation, such as specific lip geometries or filler materials that improve thermal conductivity, are crucial for demanding applications.

Proper Installation is Non-Negotiable

Even the best-designed seal will fail if installed improperly. A misaligned seal or a shaft with an imperfect surface finish will create excessive friction and localized high-temperature points, regardless of the operating parameters.

Making the Right Choice for Your Application

Your operational goals will determine how you balance the parameters of speed and pressure to ensure reliable performance.

- If your primary focus is high-speed rotation: Prioritize a seal design with a low radial load and ensure excellent shaft surface finish to minimize frictional heat generation.

- If your primary focus is containing high pressure: Select a robust seal profile designed to handle high contact forces and consider that you may need to limit the rotational speed to stay within the material's thermal limits.

- If you require both high speed and high pressure: This is the most demanding scenario, requiring a systems approach that includes advanced seal materials, optimized heat dissipation features, and potentially external cooling or enhanced lubrication.

Ultimately, successful seal performance depends on treating speed and pressure as interconnected variables in a single thermal system.

Summary Table:

| Parameter | Effect on Seal Temperature | Key Consideration |

|---|---|---|

| Rotational Speed | Increases due to higher friction over time | PTFE handles high speeds (up to 10,000 sfpm) well |

| System Pressure | Increases due to greater lip contact force | Can create damaging hot spots on the seal lip |

| Combined (PV Limit) | Multiplicative effect; greatest risk of overheating | Speed and pressure have an inverse relationship |

Struggling with seal failure from heat, speed, or pressure? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to ensure your application runs reliably. Contact our experts today to discuss your specific requirements and achieve a perfect thermal balance for your seals.

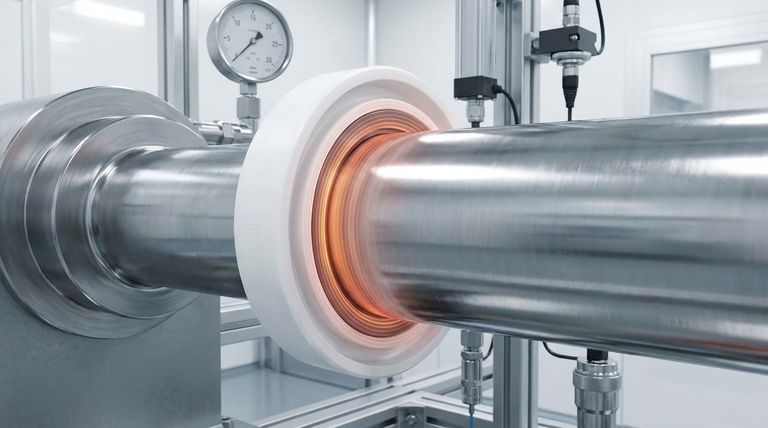

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the typical bond strength of etched PTFE to metals? Achieve Reliable Sealing & Positioning

- How does the lifecycle cost of Teflon gland packing compare to traditional materials? Achieve Lower Total Cost of Ownership

- What support is available for selecting the right PTFE valve design and size? Get Expert Guidance for Your Application

- What are the common plumbing applications of PTFE? Ensure Leak-Proof, Durable Seals

- How do PTFE washers provide electrical insulation? Ensure Reliable Circuit Protection

- What are the steps involved in PTFE isostatic pressing? A Guide to Uniform, Complex Parts

- How does the low spring rate of PTFE benefit bellows applications? Absorb Vibration and Protect Fragile Equipment

- How does the PTFE lining extend the valve's service life? The Ultimate Shield Against Corrosion and Wear