At their core, both PTFE and PFA are high-performance fluoropolymers used in valves for their exceptional chemical resistance, but they are not interchangeable. PFA (Perfluoroalkoxy) is best understood as a more robust, melt-processable version of PTFE (Polytetrafluoroethylene), offering superior mechanical strength and stability under extreme thermal and pressure conditions.

The choice between PTFE and PFA valves is a classic engineering trade-off. Your decision hinges on whether the demanding conditions of your application—specifically high pressure, abrasive media, or frequent temperature cycling—justify the higher performance and cost of PFA.

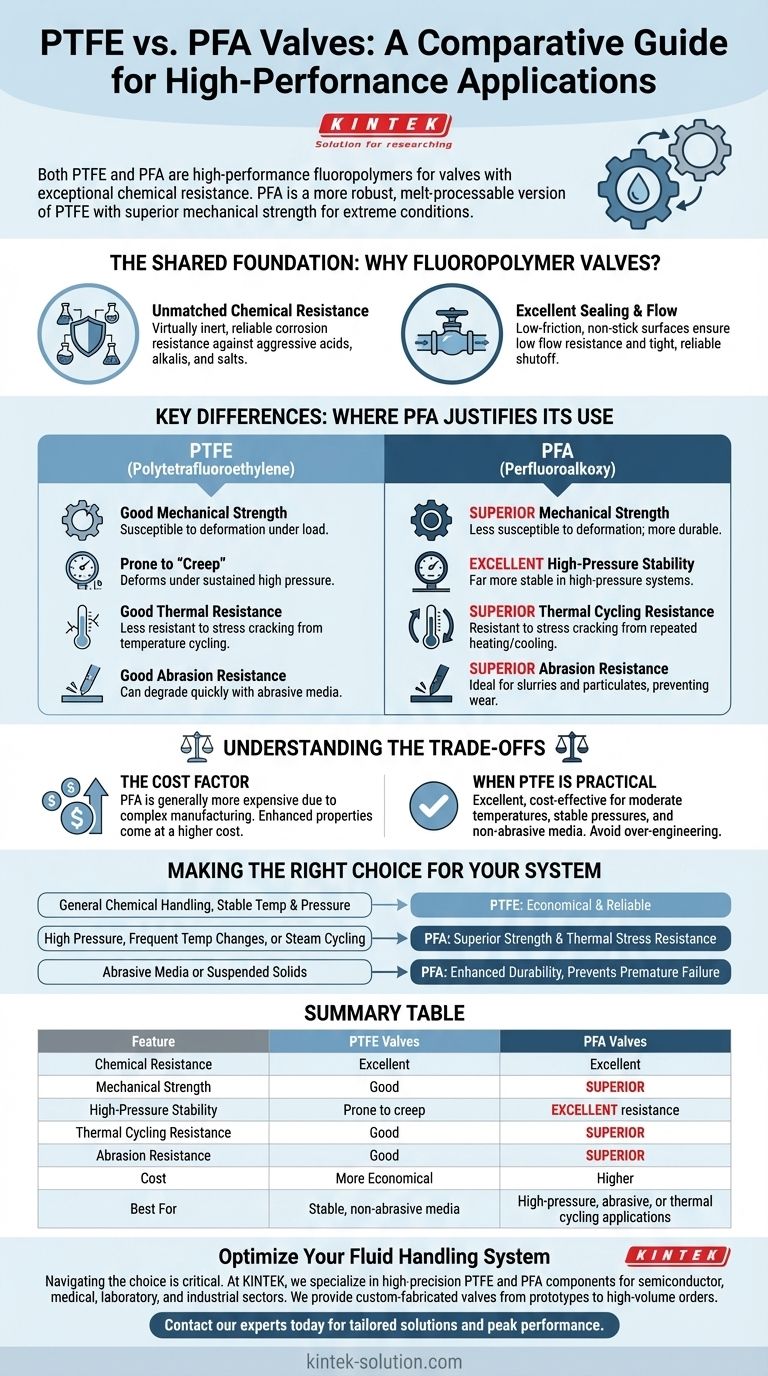

The Shared Foundation: Why Fluoropolymer Valves?

Before dissecting the differences, it's crucial to understand why both materials are industry standards for handling aggressive media. They share a powerful set of baseline characteristics.

Unmatched Chemical Resistance

Both PTFE and PFA are virtually inert. They provide reliable corrosion resistance against a vast range of weak and strong chemical media, including aggressive acids, alkalis, and salts.

Excellent Sealing and Flow

The low-friction, non-stick surfaces of both materials result in valves with low flow resistance and excellent flow characteristics. As soft-sealing materials, they also ensure a tight, reliable shutoff.

Key Differences: Where PFA Justifies Its Use

While both materials are chemically similar, their physical properties diverge significantly. PFA was developed to overcome some of the mechanical limitations inherent in PTFE.

Superior Mechanical Strength

This is the most critical distinction. PFA possesses significantly better mechanical strength than PTFE.

This means PFA is less susceptible to deformation under load and more resistant to physical wear and tear, making it a more durable choice in demanding environments.

Performance Under High Pressure

PTFE can be prone to "creep" or cold flow, where the material slowly deforms under sustained pressure. PFA's superior strength makes it far more stable in high-pressure systems.

Resistance to Thermal Cycling

PFA is better equipped to handle repeated heating and cooling cycles. Its structure is more resistant to the stress cracking that can occur from thermal expansion and contraction, ensuring longer service life in systems with fluctuating temperatures.

Durability Against Abrasive Media

For applications involving slurries or media containing particulates, PFA is the superior choice. Its enhanced mechanical strength provides greater resistance to the abrasive wear that can quickly degrade a softer PTFE lining.

Understanding the Trade-offs

Choosing the right material requires an objective look at the full picture, including limitations and cost.

The Cost Factor

PFA is generally more expensive than PTFE. This is due to a more complex manufacturing process. The enhanced mechanical properties come at a higher material cost.

When PTFE is the Practical Choice

For a vast number of applications with moderate temperatures, stable pressures, and non-abrasive media, PTFE is an excellent and highly cost-effective solution. Using PFA in such a scenario would be over-engineering and an unnecessary expense.

Making the Right Choice for Your System

Your selection should be dictated entirely by the specific operational demands of your process.

- If your primary focus is general chemical handling at stable temperatures and pressures: PTFE provides the necessary chemical resistance and is the most economical and reliable choice.

- If your system involves high pressure, frequent temperature changes, or steam cycling: PFA's superior mechanical strength and resistance to thermal stress are essential for long-term reliability.

- If your media is abrasive or contains suspended solids: PFA's enhanced durability makes it the only suitable option to prevent premature valve failure.

Ultimately, selecting the correct material is a critical step in designing a safe, efficient, and reliable fluid control system.

Summary Table:

| Feature | PTFE Valves | PFA Valves |

|---|---|---|

| Chemical Resistance | Excellent | Excellent |

| Mechanical Strength | Good | Superior |

| High-Pressure Stability | Prone to creep | Excellent resistance |

| Thermal Cycling Resistance | Good | Superior |

| Abrasion Resistance | Good | Superior |

| Cost | More Economical | Higher |

| Best For | Stable, non-abrasive media | High-pressure, abrasive, or thermal cycling applications |

Optimize your fluid handling system with the right fluoropolymer valve.

Navigating the choice between PTFE and PFA is critical for the safety and longevity of your operations. At KINTEK, we specialize in manufacturing high-precision PTFE and PFA components for the semiconductor, medical, laboratory, and industrial sectors.

We can help you select the ideal material and provide custom-fabricated valves—from prototypes to high-volume orders—that meet your exact specifications for chemical resistance, pressure, and temperature.

Contact our experts today to discuss your application requirements and receive a tailored solution that ensures peak performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE adapted for semiconductor environments? Leveraging Inertness and Anti-Static Grades for Chip Fab

- What temperature range can PTFE lined butterfly valves handle? The Critical Limits for Safe Operation

- How should one choose between PEEK and PTFE backup rings? A Guide to Maximizing Seal Performance

- What are the key technical features of Teflon backup rings? Essential Support for High-Pressure Seals

- What role does Teflon sheet play in the packaging industry? Ensuring Clean, Non-Stick Heat Sealing

- What are the benefits of using PTFE lined valves? Achieve Superior Reliability in Corrosive Applications

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- What are the operating parameters for PTFE bellow mechanical seals? A Guide to Reliable Performance in Corrosive Environments