In short, PTFE rotary shaft seals perform exceptionally well in chemical processing environments. Their primary advantage is a near-universal chemical inertness, allowing them to resist degradation from highly corrosive media like strong acids, organic solvents, and hydrocarbon-based fuels. This resilience makes them a default choice for applications where reliability and minimal maintenance are critical.

The core reason to specify PTFE seals in chemical processing is their inherent stability. Unlike traditional elastomers, PTFE's molecular structure is non-reactive, preventing the swelling, hardening, or general degradation that causes seal failure in aggressive chemical environments.

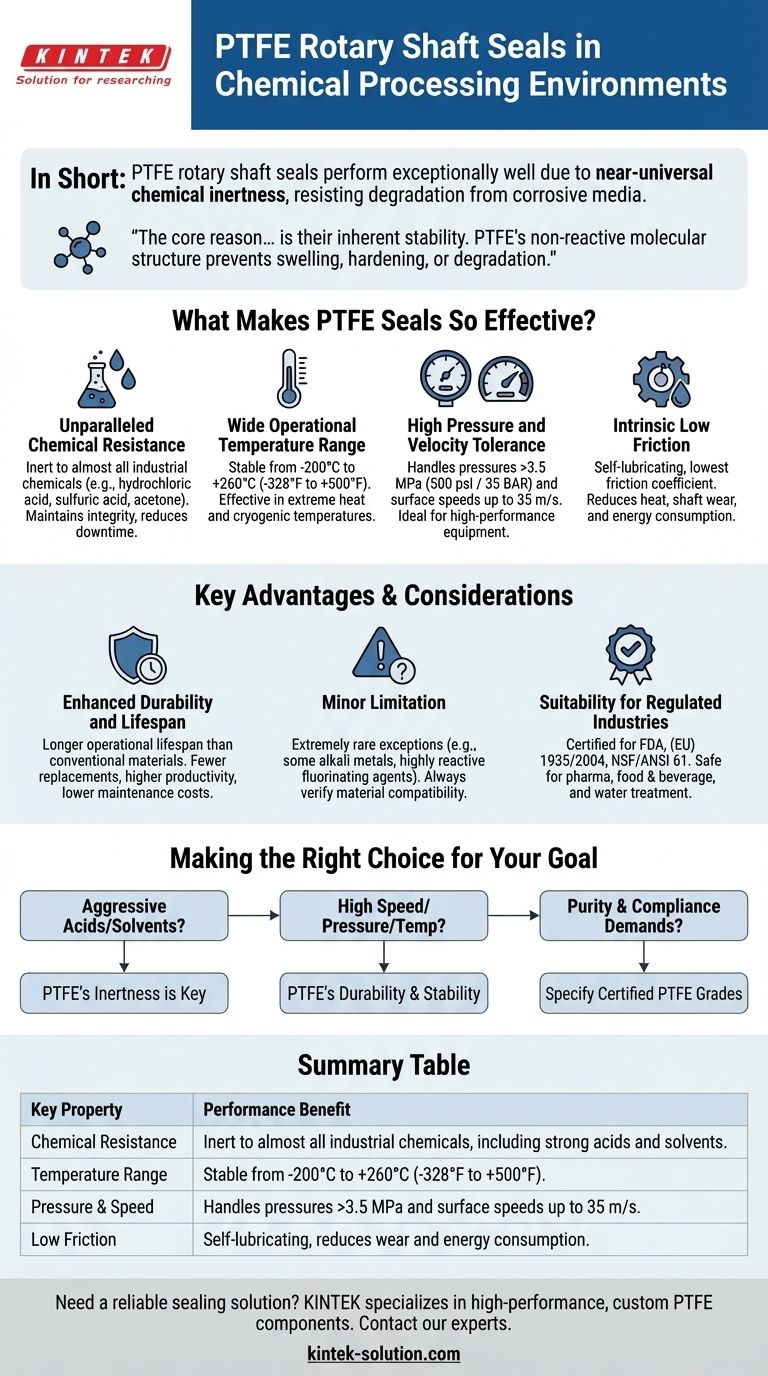

What Makes PTFE Seals So Effective?

The performance of PTFE seals is not based on a single attribute but on a combination of powerful material properties. Each one contributes to their reliability in demanding conditions.

Unparalleled Chemical Resistance

PTFE is inert to almost all industrial chemicals. This includes substances notorious for degrading other materials, such as hydrochloric acid, sulfuric acid, acetone, and sodium peroxide.

This property ensures the seal maintains its structural integrity and sealing capability over a long service life, directly reducing equipment downtime.

Wide Operational Temperature Range

These seals function effectively across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows them to be used in processes involving extreme heat or cryogenic temperatures without becoming brittle or losing their sealing force.

High Pressure and Velocity Tolerance

PTFE seals are engineered for high-performance dynamic applications. They can handle pressures exceeding 3.5 MPa (500 psi / 35 BAR) and surface speeds up to 35 m/s.

This makes them ideal for high-speed mixers, pumps, and other rotating equipment common in chemical plants.

Intrinsic Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. Its self-lubricating properties reduce heat generation at the contact point, minimizing shaft wear and energy consumption.

This also means they are compatible with most lubricants and can even perform in dry-running conditions for short periods.

Important Considerations and Key Advantages

While its chemical resistance is the primary driver, other factors make PTFE a strategic choice. Understanding these helps in appreciating its full value.

Enhanced Durability and Lifespan

The combination of chemical, thermal, and mechanical resilience results in a significantly longer operational lifespan compared to many conventional sealing materials.

Fewer seal replacements translate directly to higher plant productivity and lower long-term maintenance costs.

Acknowledging a Minor Limitation

While its chemical resistance is extensive, PTFE is not entirely invincible. Extremely rare compounds, such as certain alkali metals and highly reactive fluorinating agents, can attack the material.

It is always critical to verify material compatibility against your specific process chemistry, especially when dealing with exotic substances.

Suitability for Regulated Industries

Many PTFE compounds are certified for use in highly regulated environments. This includes compliance with FDA standards for food contact, (EU) 1935/2004, and NSF/ANSI 61 for drinking water systems.

This makes them a safe and compliant choice for pharmaceutical, food and beverage, and water treatment applications where purity is non-negotiable.

Making the Right Choice for Your Goal

Selecting a seal requires matching its strengths to your primary operational challenge.

- If your primary focus is handling aggressive acids, solvents, or mixed media: PTFE's near-universal chemical inertness is your greatest asset, ensuring seal integrity and preventing process contamination.

- If your process involves high speeds, pressures, or extreme temperatures: PTFE's physical durability and thermal stability provide a reliable sealing solution where other materials would quickly fail.

- If your application demands purity and regulatory compliance: Specify certified PTFE grades to meet stringent FDA, NSF, or other industry standards for sanitary processes.

Ultimately, choosing a PTFE rotary shaft seal is a decision for operational stability and long-term reliability in chemically aggressive applications.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Chemical Resistance | Inert to almost all industrial chemicals, including strong acids and solvents. |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F). |

| Pressure & Speed | Handles pressures >3.5 MPa and surface speeds up to 35 m/s. |

| Low Friction | Self-lubricating, reduces wear and energy consumption. |

Need a reliable sealing solution for your aggressive chemical process?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates with maximum uptime and minimal maintenance.

Contact our experts today to discuss your specific requirements, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE rotary seals becoming a preferred choice for engineers and OEMs? Solve Critical Performance Failures

- What industries commonly use PTFE Bellows and for what purposes? Critical Applications in Chemical & Semiconductor

- What are the key advantages of PTFE bushings for high-speed and high-temperature applications? Unlock Maintenance-Free Performance

- What are the tensile strengths of PTFE and graphite packing? Choosing the Right Material for Your Application

- What are the characteristics of PTFE coatings? Unlock Extreme Performance for Your Components

- Why are pressure conditions important when choosing PTFE packing? Ensure a Reliable Seal for Your System

- How do you select the right PTFE gasket for an application? A Guide to Matching Material to Your Demands

- How does Teflon benefit the chemical processing industry? Enhance Safety, Purity, and Equipment Life