At its core, a PTFE gasket prevents leaks by physically deforming under compression to fill the microscopic imperfections between a ball valve's internal components. This action creates a solid, impermeable barrier that is exceptionally resistant to chemicals and pressure, ensuring a secure and reliable seal.

The true effectiveness of a PTFE gasket in a ball valve lies not just in its ability to plug a gap, but in its unique combination of conformability, chemical inertness, and extremely low friction, which together create a durable seal that also enhances the valve's operational lifespan.

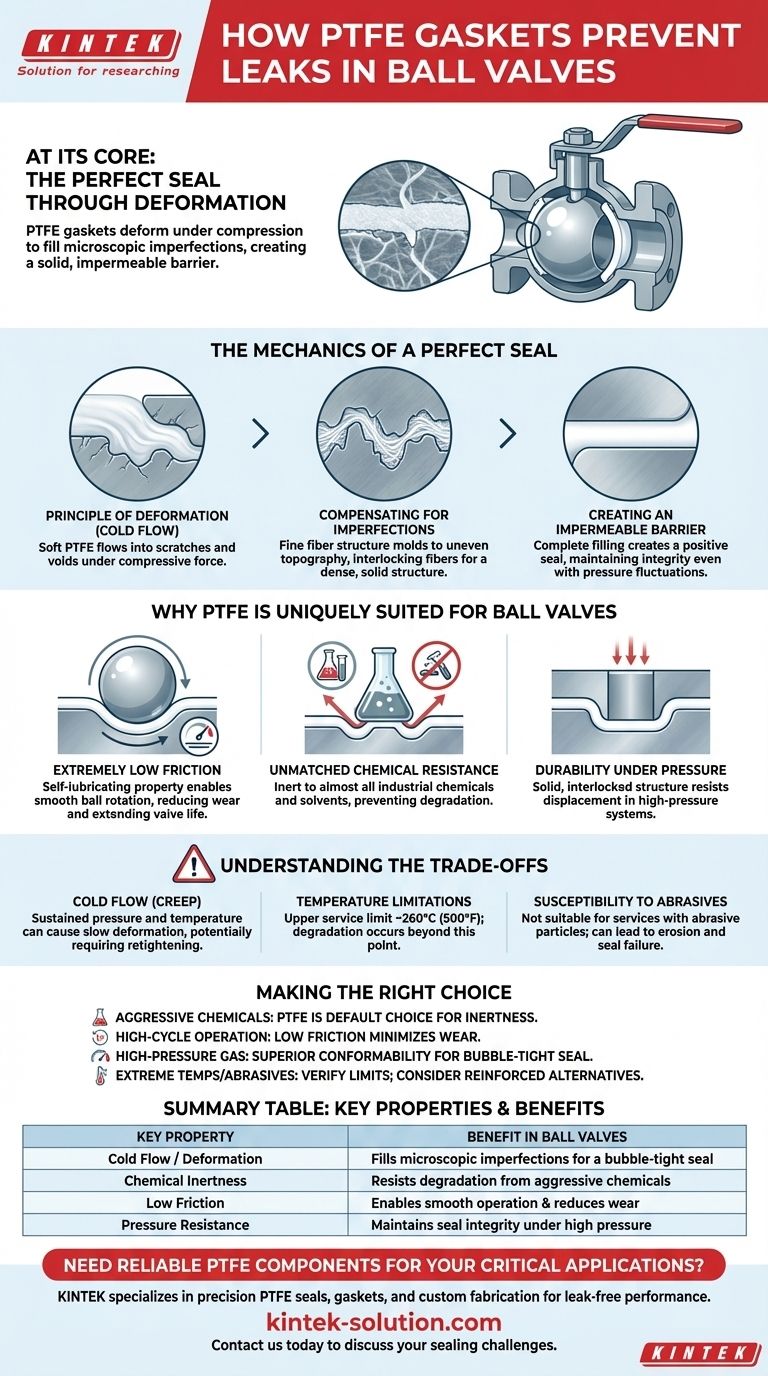

The Mechanics of a Perfect Seal

To understand why PTFE is so effective, we must look at how it behaves on a microscopic level when installed in a valve.

The Principle of Material Deformation

PTFE is a soft polymer with a unique property often referred to as "cold flow." When compressive force is applied (for example, by tightening the valve body), the PTFE material flows into and fills every tiny scratch, void, and irregularity on the metal sealing surfaces.

Compensating for Surface Imperfections

No machined metal surface is perfectly smooth. Under a microscope, it has peaks and valleys. PTFE’s fine, bi-directional fiber structure allows it to mold itself perfectly to this uneven topography.

As the gasket is compressed, these fibers interlock, transforming from an elastic material into a dense and solid structure that leaves no path for fluid or gas to escape.

Creating an Impermeable Barrier

This complete filling of all voids creates a positive seal. The gasket effectively becomes one with the metal surfaces, forming a continuous, leak-proof barrier that maintains its integrity even as pressure in the system fluctuates.

Why PTFE is Uniquely Suited for Ball Valves

A ball valve is a dynamic component; it opens and closes with a rotational movement. The sealing material must accommodate this movement without failing.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, similar to wet ice on wet ice. This self-lubricating property is critical.

It allows the ball to rotate smoothly against the gasket (or seat) without galling, sticking, or shredding the sealing material. This drastically reduces wear and tear, leading to a longer service life for the valve.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the ideal choice for demanding applications in the chemical processing and pharmaceutical industries.

The gasket material will not swell, degrade, or break down when exposed to aggressive media, ensuring the seal remains reliable over time.

Durability Under Pressure

The solid, interlocked structure formed by compressed PTFE is strong enough to resist being pushed out of place, even in high-pressure systems. This ability to maintain its shape and position is fundamental to long-term, leak-free performance.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Acknowledging its limitations is key to proper application.

The Limit of Cold Flow (Creep)

The same "cold flow" that allows PTFE to create a great seal can also be a liability. Under sustained pressure and temperature, the material can continue to slowly deform, or "creep."

This can lead to a loss of bolt torque in flanged connections over time, potentially requiring periodic re-tightening to maintain seal integrity.

Temperature Limitations

While PTFE has good temperature resistance, it has a distinct upper service limit (typically around 260°C or 500°F). Beyond this point, it begins to degrade, losing its mechanical properties and releasing hazardous fumes.

Susceptibility to Abrasives

As a relatively soft material, standard PTFE is not well-suited for services containing abrasive particles, such as slurries. Abrasive media can quickly erode the gasket material, leading to premature seal failure.

Making the Right Choice for Your Application

Selecting a gasket is about matching the material's properties to the specific demands of your system.

- If your primary focus is aggressive chemical processing: PTFE is the default choice due to its exceptional chemical inertness.

- If your primary focus is high-cycle valve operation: The self-lubricating, low-friction nature of PTFE minimizes wear and extends the valve's service life.

- If your primary focus is high-pressure gas service: The superior conformability of PTFE creates the bubble-tight seal essential for preventing dangerous leaks.

- If your system involves extreme temperatures or abrasive media: You must verify that standard PTFE is within its operational limits and consider reinforced alternatives like filled-PTFE or different material classes entirely.

Ultimately, a PTFE gasket allows a ball valve to function reliably not just by sealing a gap, but by creating a durable, low-friction interface that enhances total system integrity.

Summary Table:

| Key Property | Benefit in Ball Valves |

|---|---|

| Cold Flow / Deformation | Fills microscopic imperfections for a bubble-tight seal |

| Chemical Inertness | Resists degradation from aggressive chemicals and solvents |

| Low Friction | Enables smooth valve operation and reduces wear |

| Pressure Resistance | Maintains seal integrity under high-pressure conditions |

Need reliable PTFE components for your critical applications?

KINTEK specializes in manufacturing precision PTFE seals, gaskets, liners, and labware for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact PTFE solution your ball valves require for leak-free performance.

Contact us today to discuss your specific sealing challenges and discover how our expertise in PTFE components can enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability