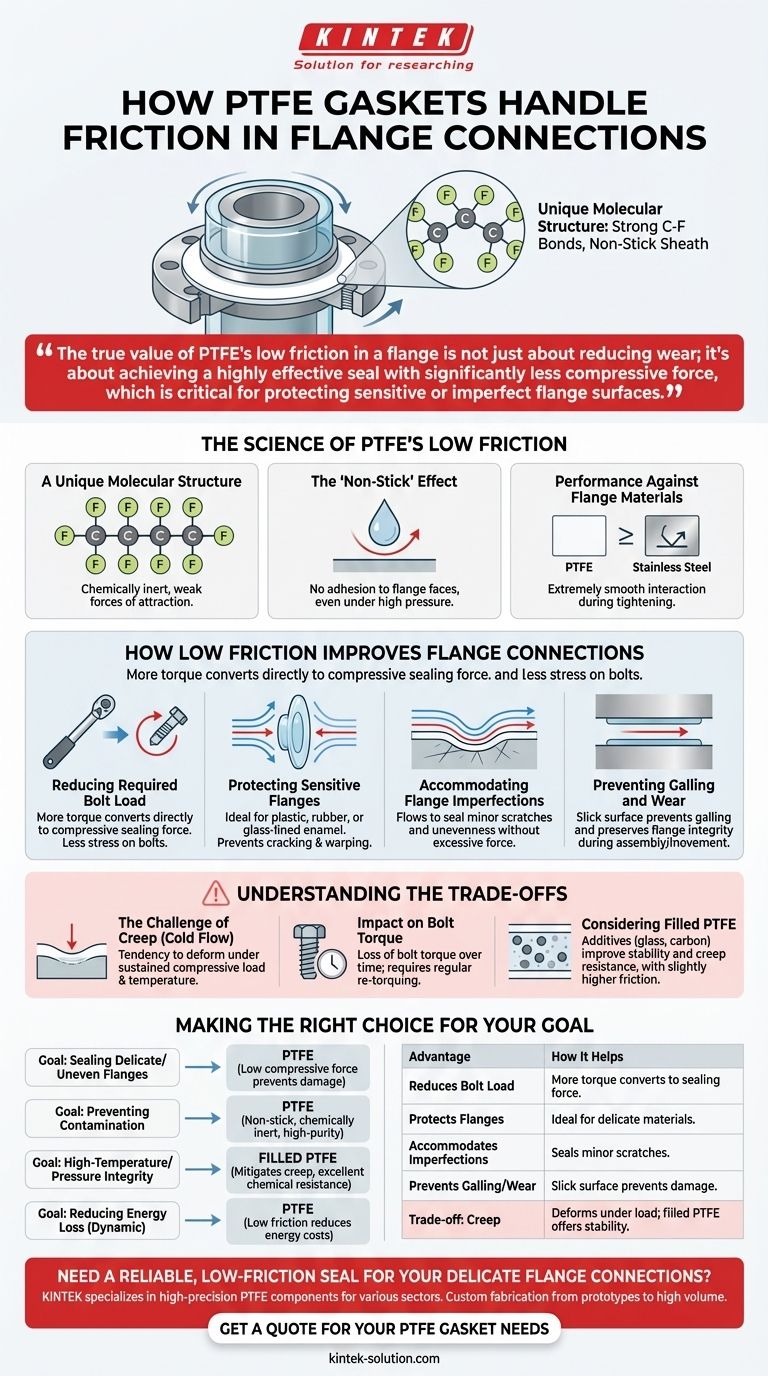

At its core, a Polytetrafluoroethylene (PTFE) gasket handles friction in a flange connection by possessing one of the lowest coefficients of friction of any solid material. Its unique molecular structure creates an incredibly smooth, non-stick surface. This allows the flange faces to slide and compress against the gasket with minimal resistance, ensuring the applied bolt load translates directly into sealing pressure rather than being lost to friction.

The true value of PTFE's low friction in a flange is not just about reducing wear; it's about achieving a highly effective seal with significantly less compressive force, which is critical for protecting sensitive or imperfect flange surfaces.

The Science of PTFE's Low Friction

PTFE's exceptional low-friction properties are not an additive or a coating; they are an inherent part of the material's chemistry. Understanding this is key to appreciating its function in a gasket.

A Unique Molecular Structure

PTFE's carbon-fluorine bonds are incredibly strong and stable. The fluorine atoms form a tight, uniform sheath around the carbon backbone, creating a molecule that is chemically inert and has very weak forces of attraction to other surfaces.

The "Non-Stick" Effect

This molecular sheath is what gives PTFE its famous "non-stick" quality. In a flange connection, this means the gasket material does not adhere to the metal, plastic, or enamel faces, even under high pressure.

Performance Against Flange Materials

This quality is especially pronounced when PTFE is paired with common flange materials. The coefficient of friction between PTFE and stainless steel, for example, is one of the lowest recorded between two solids, ensuring an extremely smooth interaction during tightening.

How Low Friction Improves Flange Connections

The theoretical benefit of low friction translates into several practical advantages that ensure a more reliable and durable seal.

Reducing Required Bolt Load

Because very little energy is wasted overcoming friction, more of the torque applied to the bolts is converted directly into compressive, sealing force. This means a reliable seal can be achieved with less stress on the bolts and flanges.

Protecting Sensitive Flanges

This ability to seal with low surface compression is crucial for delicate flanges. Materials like plastic, rubber, or glass-lined enamel can crack, warp, or deform under the high bolt loads required by other gasket types. PTFE minimizes this risk.

Accommodating Flange Imperfections

The low friction allows the gasket material to flow and conform more easily into minor surface imperfections, such as scratches or slight unevenness. This creates a superior seal without needing excessive force to flatten the flange faces.

Preventing Galling and Wear

During assembly, thermal expansion, or pressure fluctuations, flange faces can move slightly against the gasket. PTFE’s slick surface prevents galling (a form of wear caused by adhesion between sliding surfaces) on the flange faces, preserving their integrity for future use.

Understanding the Trade-offs

While its low friction is a powerful advantage, PTFE is not a universal solution. An objective assessment requires acknowledging its mechanical limitations.

The Challenge of Creep (Cold Flow)

The primary trade-off for PTFE's flexibility is its tendency to creep, or cold flow. Under sustained compressive load, especially at elevated temperatures, the material can slowly deform and flow out of the flange.

Impact on Bolt Torque

This creep can lead to a loss of bolt torque over time, potentially compromising the seal's integrity. Regular maintenance checks and re-torquing of bolts may be necessary in critical or high-temperature applications.

Considering Filled PTFE

To counteract creep, various fillers (like glass, carbon, or graphite) are often added to PTFE. These "filled PTFE" gaskets offer improved mechanical stability and creep resistance, though sometimes at the cost of a slightly higher coefficient of friction.

Making the Right Choice for Your Goal

Selecting the correct gasket requires matching the material's properties to the system's demands.

- If your primary focus is sealing delicate or uneven flanges: PTFE's ability to create a seal with low compressive force makes it the ideal choice to prevent damage to plastic, glass-lined, or other sensitive materials.

- If your primary focus is preventing contamination: The non-stick, chemically inert surface of PTFE is superior for applications in food, pharmaceutical, or high-purity chemical processing.

- If your primary focus is high-temperature or high-pressure integrity: Consider a filled PTFE or composite gasket that mitigates the risk of creep while still offering excellent chemical resistance.

- If your primary focus is reducing energy loss in dynamic systems: While less common for static gaskets, PTFE's low friction directly reduces energy costs in any application with moving parts, such as in certain valve designs.

By understanding that PTFE's low friction directly enables lower-stress sealing, you can make a more informed decision for your specific flange connection.

Summary Table:

| Advantage | How PTFE's Low Friction Helps |

|---|---|

| Reduces Bolt Load | More torque converts to sealing force, not wasted overcoming friction. |

| Protects Flanges | Ideal for delicate materials like plastic, glass-lined, or enamel. |

| Accommodates Imperfections | Material flows easily to seal minor scratches or unevenness. |

| Prevents Galling/Wear | Slick surface prevents damage to flange faces during assembly or movement. |

| Trade-off: Creep | PTFE can deform under sustained load; filled PTFE offers more stability. |

Need a reliable, low-friction seal for your delicate or specialized flange connections?

KINTEK specializes in manufacturing high-precision PTFE components, including gaskets and seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a gasket that provides an effective seal while protecting your valuable flange surfaces from damage.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact us today to discuss your application and let our precision production work for you.

Get a Quote for Your PTFE Gasket Needs

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common applications of PTFE sheets? Solve Extreme Chemical, Friction & Temperature Challenges

- What are the pressure-temperature limitations for polymer seats in high performance butterfly valves? Avoid Costly Valve Failures

- What temperature can heat-resistant Teflon sheets withstand? Up to 500°F for Reliable Performance

- Why is 5-axis CNC machining commonly used for Teflon? Master Complex PTFE Parts with Precision

- What is the significance of the low friction coefficient in PTFE processing machines? Enhance Quality and Machine Life

- What advantages do Teflon washers have over nylon and plastic washers? Achieve Superior Performance in Harsh Environments

- How do PTFE and graphite packing compare in terms of corrosion resistance? Selecting the Right Material for Your Application

- How does PTFE's high-temperature tolerance benefit shaft seals? Ensure Reliability in Extreme Heat