To be direct, PTFE envelope gaskets offer excellent leakage prevention for both gases and liquids. Their composite design, which combines a resilient inner core with a protective Polytetrafluoroethylene (PTFE) shell, creates a highly reliable seal with a very low leakage rate suitable for a wide range of demanding industrial applications.

The true effectiveness of a PTFE envelope gasket lies not just in the PTFE itself, but in the synergy between the chemically inert PTFE outer layer and the mechanical properties of its inner core material. This dual-material construction is the key to its reliable sealing performance.

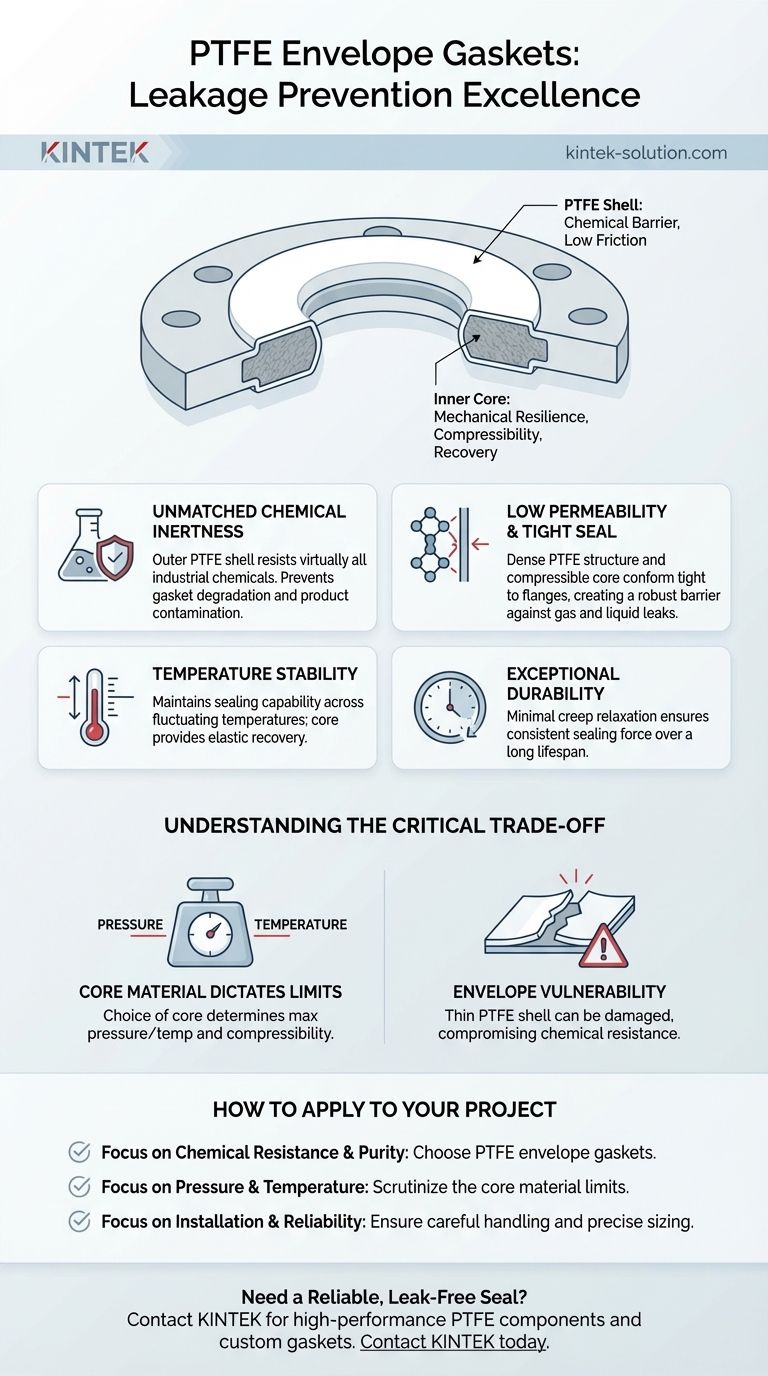

What Makes PTFE Envelope Gaskets So Effective?

The low leakage rate of these gaskets is not accidental. It is the direct result of a design that leverages the distinct advantages of two different materials working in concert.

The "Envelope" Design Principle

A PTFE envelope gasket consists of a core material, such as compressed non-asbestos fiber or rubber, which is encapsulated in a thin "envelope" of PTFE.

This design provides the chemical resistance and non-stick properties of solid PTFE, but with the added mechanical resilience, compressibility, and recovery of the core material.

Unmatched Chemical Inertness

The outer PTFE shell is virtually inert and resistant to almost all industrial chemicals. This prevents the gasket itself from degrading, swelling, or leaching, which are common causes of seal failure and media contamination.

Low Permeability and Tight Sealing

PTFE has a fine, dense molecular structure that gives it very low gas permeability. When combined with a compressible core, the gasket can conform tightly to flange imperfections, creating a robust physical barrier against leaks.

Stability Across a Wide Temperature Range

These gaskets maintain their integrity and sealing capability across fluctuating process temperatures. The PTFE shell remains stable while the core material provides the necessary elastic recovery to maintain a constant sealing pressure.

Key Properties Driving Sealing Performance

Several inherent properties work together to ensure a durable, leak-free seal over the gasket's operational life.

Exceptional Durability and Lifespan

PTFE envelope gaskets exhibit minimal creep relaxation, meaning they resist the tendency to thin out or flow away from the flange face under load and temperature. This ensures they maintain a consistent sealing force over a long service life, reducing the need for frequent replacement.

Prevention of Product Contamination

The non-stick, chemically pure surface of the PTFE envelope is critical for industries like pharmaceuticals, food and beverage, and electronics. It prevents process media from adhering to the gasket and ensures the final product remains uncontaminated.

Adaptability for a Precise Fit

These gaskets can be customized to fit nearly any flange size or configuration. Achieving a precise fit is fundamental to effective sealing, as it eliminates gaps and ensures uniform compression across the entire sealing surface.

Understanding the Critical Trade-off: The Core Material

While the PTFE envelope provides the chemical interface, the gasket's mechanical performance is dictated entirely by its inner core. Understanding this is crucial to avoiding failure.

The Core Dictates Mechanical Limits

The choice of core material determines the gasket's maximum temperature and pressure ratings, as well as its compressibility and recovery characteristics. A rubber core offers excellent conformability at lower temperatures, while a non-asbestos fiber core may be specified for higher temperatures and pressures.

Vulnerability of the Envelope

The PTFE envelope is relatively thin and can be scratched or damaged during handling or installation. Any breach in the envelope compromises its chemical resistance and can lead to a premature failure of the inner core material and a subsequent leak.

Not a Universal Solution for High Pressure

While robust, PTFE envelope gaskets are typically best suited for low- to moderate-pressure applications. In extremely high-pressure systems, a solid metal or spiral-wound gasket may provide a more reliable seal, as they are engineered specifically to withstand immense mechanical stress.

How to Apply This to Your Project

Your gasket selection must align with the specific demands of your system. Use these guidelines to make an informed choice.

- If your primary focus is chemical resistance and purity: PTFE envelope gaskets are an ideal choice, as the inert shell directly prevents media contamination and chemical attack.

- If your primary focus is pressure and temperature: Scrutinize the gasket's core material, as this, not the PTFE, dictates the gasket's mechanical limits.

- If your primary focus is installation and reliability: Ensure careful handling to protect the thin PTFE envelope and confirm the gasket is correctly sized for your flange to guarantee a uniform seal.

Making the right choice depends on understanding that you are selecting a complete sealing system, not just a piece of PTFE.

Summary Table:

| Property | Impact on Leakage Prevention |

|---|---|

| Envelope Design | Combines PTFE's chemical inertness with a resilient core for a robust, conforming seal. |

| Chemical Inertness | Prevents gasket degradation, a common cause of seal failure and leaks. |

| Low Permeability | Dense PTFE structure creates an effective barrier against gas and liquid leaks. |

| Temperature Stability | Maintains sealing integrity and pressure across a wide operating range. |

Need a reliable, leak-free seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. Our precision production ensures a perfect fit and superior sealing performance for the semiconductor, medical, laboratory, and industrial sectors. We work with you from prototype to high-volume production to deliver a sealing solution that meets your exact chemical, temperature, and pressure requirements.

Contact KINTEK today to discuss your project and get a quote for custom PTFE gaskets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection