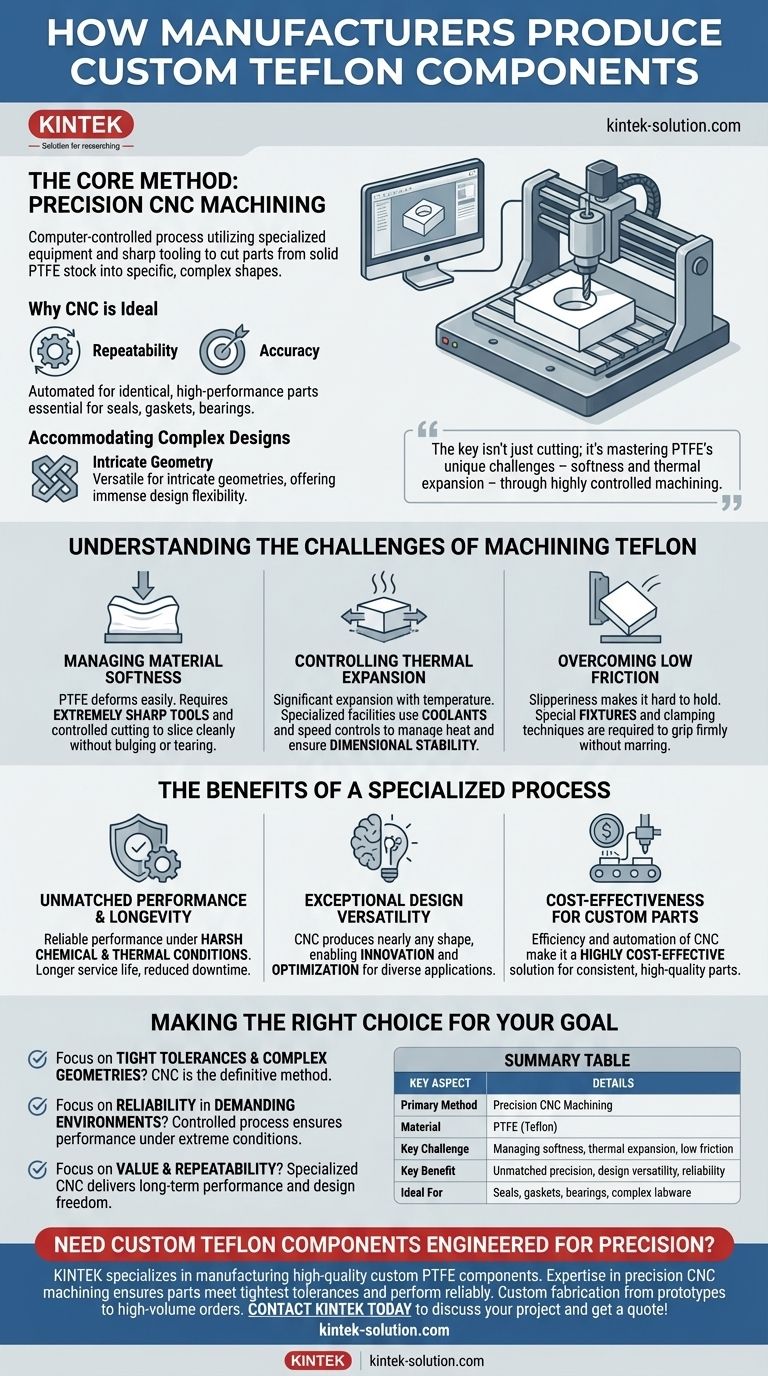

In short, manufacturers produce custom Teflon components using precision CNC machining. This computer-controlled process utilizes specialized equipment and sharp tooling to cut parts from solid stock of PTFE (the chemical name for Teflon) into highly specific and complex shapes with tight tolerances.

The key to manufacturing custom Teflon parts isn't just about cutting the material; it's about mastering the unique challenges of PTFE, such as its softness and thermal expansion, through a highly controlled and specialized machining process.

The Core Manufacturing Method: Precision CNC Machining

Computer Numerical Control (CNC) machining is the foundational technology for creating custom Teflon components. It is a subtractive manufacturing process, meaning it carves a final part out of a larger block of material.

Why CNC is Ideal for Teflon (PTFE)

CNC machining provides the repeatability and accuracy essential for high-performance parts. The process is automated based on a digital design file, ensuring every component is identical.

This precision is critical for parts like seals, gaskets, and bearings, where even minor deviations in size or shape can lead to failure.

Accommodating Complex Designs

The versatility of CNC equipment allows for the creation of intricate geometries that would be impossible with other methods. This gives engineers immense flexibility in component design, enabling them to create parts perfectly suited for specific, demanding applications.

Understanding the Challenges of Machining Teflon

Teflon is not like machining metal. Its unique properties require a specialized approach to achieve the desired outcome without damaging the material.

Managing Material Softness

PTFE is a relatively soft material that can easily deform or compress under pressure. Machinists must use extremely sharp tools and carefully controlled cutting parameters to slice through the material cleanly without causing it to bulge or tear.

Controlling Thermal Expansion

Teflon expands and contracts significantly with temperature changes. The heat generated during machining can cause the part to change size, compromising final tolerances. Specialized facilities often employ coolants and precise speed controls to manage heat and ensure dimensional stability.

Overcoming Low Friction

The very property that makes Teflon useful—its slipperiness—also makes it difficult to hold securely during the machining process. Special fixtures and clamping techniques are required to grip the material firmly without marring its surface.

The Benefits of a Specialized Process

By mastering these challenges, manufacturers deliver custom components with significant advantages for critical applications.

Unmatched Performance and Longevity

Precisely machined Teflon parts perform reliably under the most harsh chemical and thermal conditions. This leads to a longer service life for the component, reducing downtime and maintenance costs.

Exceptional Design Versatility

Because CNC machining can produce nearly any shape, engineers are not limited by traditional manufacturing constraints. This allows for innovation and optimization in a wide range of applications, from aerospace to medical devices.

Cost-Effectiveness for Custom Parts

While the initial setup for a custom part requires expertise, the efficiency and automation of CNC machining make it a highly cost-effective solution for producing consistent, high-quality components, especially for low-to-medium volume runs.

Making the Right Choice for Your Goal

Understanding this process helps you specify components that meet your exact needs.

- If your primary focus is tight tolerances and complex geometries: CNC machining is the definitive method for producing intricate and precise Teflon components.

- If your primary focus is reliability in demanding environments: The controlled process ensures your custom parts will perform as expected under extreme temperatures or chemical exposure.

- If your primary focus is value and repeatability: A specialized CNC process delivers the long-term performance and design freedom that justifies the investment in custom manufacturing.

Ultimately, leveraging a specialized machining process ensures your custom Teflon components are engineered for optimal performance from the start.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Method | Precision CNC Machining |

| Material | PTFE (Teflon) |

| Key Challenge | Managing softness, thermal expansion, and low friction |

| Key Benefit | Unmatched precision, design versatility, and reliability in harsh environments |

| Ideal For | Seals, gaskets, bearings, and complex labware requiring tight tolerances |

Need custom Teflon components engineered for precision and performance?

KINTEK specializes in manufacturing high-quality, custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision CNC machining ensures your parts meet the tightest tolerances and perform reliably in the most demanding environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing quality and your specific application needs.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs