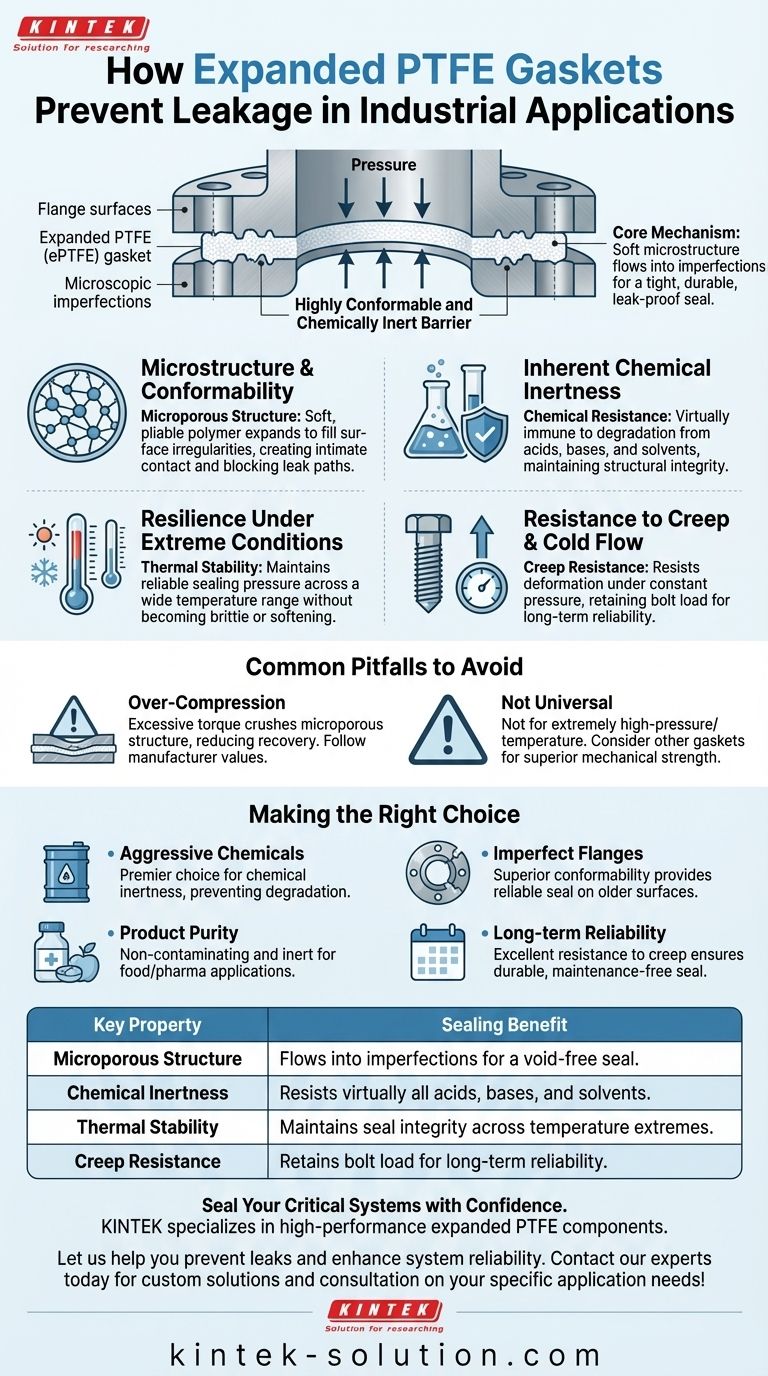

At its core, an expanded PTFE gasket prevents leaks by creating a highly conformable and chemically inert barrier. During compression, its unique, soft microstructure flows into the microscopic imperfections of flange surfaces, forming an exceptionally tight and durable seal that resists virtually all industrial chemicals and extreme temperatures.

The true effectiveness of an expanded PTFE (ePTFE) gasket lies not in one single property, but in the powerful combination of its physical structure and the inherent chemical resilience of Polytetrafluoroethylene, ensuring a long-lasting, leak-proof seal where other materials would fail.

The Sealing Mechanism: From Material to Performance

To understand how ePTFE provides such a reliable seal, we must look at its unique material properties and how they function under the pressure of a bolted flange connection.

Microstructure and Conformability

Standard PTFE is a rigid plastic. Expanded PTFE (ePTFE), however, is a soft, pliable material created by expanding the polymer. This process creates a microporous structure of nodes interconnected by fibrils.

When compressed between two flange faces, this soft structure easily deforms and flows into scratches, pits, and other surface irregularities. This creates an intimate, void-free contact between the gasket and the flanges, effectively blocking any potential leak paths.

Inherent Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to degradation from acids, bases, solvents, and other aggressive process media.

This inertness ensures the gasket material itself will not be corroded or eaten away over time. A gasket that doesn't degrade maintains its structural integrity, and therefore its ability to seal, throughout its service life.

Resilience Under Extreme Conditions

PTFE gaskets provide reliable sealing across an exceptionally wide temperature range. They do not become brittle at low temperatures or soften significantly at high temperatures.

This thermal stability allows the gasket to maintain a consistent sealing pressure even as the system undergoes thermal cycling, preventing leaks that can occur when flanges expand and contract.

Resistance to Creep and Cold Flow

A critical factor in long-term sealing is creep resistance—the material's ability to resist deforming or "flowing" out of the flange under constant pressure.

High-quality ePTFE is engineered to have excellent resistance to creep. This means it maintains the bolt load applied during installation, ensuring the seal remains tight and reliable over months or years without needing to be re-torqued.

Common Pitfalls to Avoid

While highly effective, the performance of an ePTFE gasket is dependent on understanding its unique characteristics.

The Risk of Over-Compression

The softness that makes ePTFE so conformable also makes it susceptible to over-compression. Applying excessive bolt torque can crush the gasket's microporous structure, reducing its ability to recover and maintain a seal over time.

Always follow the manufacturer's specified torque values for the specific gasket style and size you are using to ensure optimal performance.

Not a Universal Solution

Despite its versatility, ePTFE is not the ideal choice for every single application. In extremely high-pressure or high-temperature services, a spiral-wound or metallic gasket may be required for its superior mechanical strength and blowout resistance.

Understanding the pressure and temperature limits of your specific ePTFE gasket is essential for ensuring system safety and reliability.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to your primary operational goal.

- If your primary focus is aggressive chemical service: ePTFE is a premier choice due to its near-universal chemical inertness, preventing gasket degradation and leaks.

- If your primary focus is product purity in food or pharma: The non-contaminating, inert nature of ePTFE ensures it will not leach into or react with the process media.

- If your primary focus is sealing older or imperfect flange surfaces: The superior conformability of ePTFE provides a reliable seal where more rigid gaskets would likely fail.

- If your primary focus is long-term reliability with minimal maintenance: The material's excellent resistance to creep and environmental degradation ensures a durable, long-lasting seal.

Ultimately, an expanded PTFE gasket prevents leaks by combining microscopic adaptability with macroscopic resilience, creating a dependable seal for your most critical systems.

Summary Table:

| Key Property | Sealing Benefit |

|---|---|

| Microporous Structure | Flows into surface imperfections for a void-free seal. |

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Thermal Stability | Maintains seal integrity across a wide temperature range. |

| Creep Resistance | Retains bolt load for long-term reliability without re-torquing. |

Seal Your Critical Systems with Confidence

Are you facing challenges with aggressive chemicals, high-purity requirements, or imperfect flange surfaces? KINTEK specializes in manufacturing high-performance expanded PTFE (ePTFE) components, including seals, gaskets, liners, and custom labware.

Our precision-engineered PTFE solutions offer the superior conformability and chemical resistance detailed in this article, ensuring a reliable, long-lasting seal for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Let us help you prevent leaks and enhance system reliability. Contact our experts today for a consultation on your specific application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the significance of low surface adhesion in PTFE diaphragm valves for pharmaceutical research? Ensure Sample Integrity and Process Reliability

- What are POT-PTFE bearings, and how do they function? Manage Massive Loads with Precision Movement

- What are the main benefits of PTFE envelope gaskets? Achieve Superior Chemical Resistance and Sealing Integrity

- What challenges arise during the manufacturing of skived PTFE sheets? Achieving Consistent Quality and Performance

- What are some specialized industrial applications of guide rings? Essential Uses for Oil-Free and High-Load Systems

- What maintenance practices ensure optimal performance of PTFE-lined plug valves? A Proactive Guide to Reliability

- What are the two common types of PTFE structural bearings? Sliding vs. POT Bearings Explained

- What are the performance characteristics of PTFE spacers? Unlock Superior Sealing for Demanding Industries