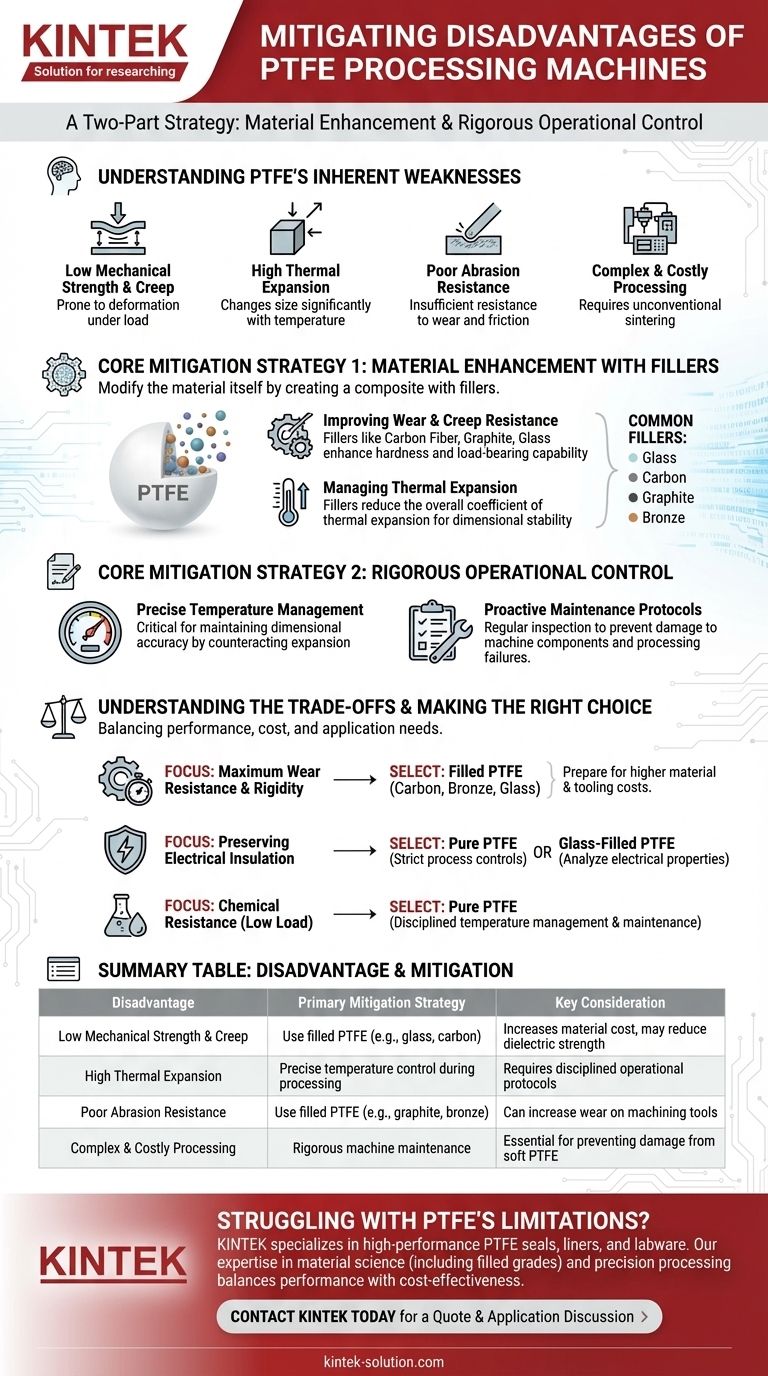

To mitigate the disadvantages of PTFE processing machines, you must employ a two-part strategy: enhancing the material itself with fillers and enforcing strict operational controls. The core issues of PTFE—its low mechanical strength, poor wear resistance, and high thermal expansion—are best managed by selecting a filled grade of PTFE for demanding applications and implementing rigorous maintenance and temperature management protocols during processing.

The central challenge with PTFE is that its remarkable chemical and thermal resistance comes at the cost of poor mechanical properties. The most effective approach is not to seek a single fix, but to understand that you are managing a series of trade-offs, balancing material composition against processing discipline to achieve your desired outcome.

Understanding PTFE's Inherent Weaknesses

Before implementing solutions, it is crucial to understand the root causes of the challenges associated with PTFE. These are not flaws in the machinery itself, but limitations of the Polytetrafluoroethylene material it is designed to process.

Low Mechanical Strength and Creep

PTFE is a relatively soft material with low mechanical tenacity. It is prone to "creep," meaning it will slowly deform over time when a load is applied and will not return to its original shape.

This makes parts like bearings or seals susceptible to damage and failure under pressure, reducing the service life of both the components being made and the machine itself.

High Thermal Expansion

The material has a large coefficient of thermal expansion, meaning it changes size significantly with temperature fluctuations.

Without precise temperature control during processing, it is difficult to achieve tight tolerances and dimensional accuracy in the final product.

Poor Abrasion Resistance

Pure PTFE has insufficient resistance to wear and abrasion. This can be a significant drawback for components that experience friction during their operational life.

This lack of durability can lead to a shorter service life for parts manufactured from pure PTFE.

Complex and Costly Processing

PTFE does not melt like conventional plastics; it sinters. This requires unconventional and complex processing methods, which contributes to the high manufacturing cost of PTFE parts and machinery.

Core Mitigation Strategy 1: Material Enhancement with Fillers

The most direct way to counteract PTFE's mechanical deficiencies is to modify the material itself. This is accomplished by adding fillers to create a composite material.

What Are Filled PTFEs?

Filled PTFE is a composite where substances like glass, carbon, graphite, or bronze are added to the virgin PTFE resin before processing.

These fillers act as reinforcements, dramatically improving the material's physical properties.

Improving Wear and Creep Resistance

Adding fillers like carbon fiber, graphite, or glass significantly enhances PTFE's hardness, wear resistance, and resistance to creep.

This makes filled PTFE suitable for high-load applications where pure PTFE would quickly fail.

Managing Thermal Expansion

Fillers also help to reduce the material's overall coefficient of thermal expansion, providing greater dimensional stability during and after processing.

Core Mitigation Strategy 2: Rigorous Operational Control

Even when using filled PTFE, success depends on how the material is handled. Strict operational discipline is non-negotiable.

Precise Temperature Management

Maintaining a stable and controlled temperature throughout the processing cycle is critical. This counteracts the material's natural tendency to expand and contract, ensuring dimensional accuracy.

Proactive Maintenance Protocols

Given PTFE's softness, regular inspection and maintenance of processing machines are essential to prevent damage. This helps identify and address wear on machine components before they lead to processing failures.

Understanding the Trade-offs

Mitigating PTFE's disadvantages always involves balancing competing factors. There is no perfect solution, only the best solution for a specific application.

The Cost of Modification

Filled PTFE grades are more expensive than pure PTFE. The performance benefits must justify the increased material cost.

Impact on Electrical Properties

Fillers fundamentally change the material's characteristics. For example, adding carbon, which is conductive, will dramatically lower the dielectric strength of PTFE, making it unsuitable for high-voltage electrical insulation.

Conversely, glass-filled PTFE maintains good dielectric strength but may have a higher dissipation factor, which can be a concern in high-frequency applications.

The Challenge of Machinability

While fillers improve the final part's durability, they can make the material more abrasive. This can increase wear on cutting tools and require adjustments to machining parameters.

Making the Right Choice for Your Application

Your strategy for mitigating PTFE's disadvantages should be driven entirely by your end goal.

- If your primary focus is maximum wear resistance and rigidity: Select a filled PTFE with carbon, bronze, or glass, and be prepared for the higher material and tooling costs.

- If your primary focus is preserving electrical insulation: Use pure PTFE and rely on strict process controls, or choose a glass-filled grade while carefully analyzing its electrical properties for your specific use case.

- If your primary focus is chemical resistance in a low-load environment: Pure PTFE is often sufficient, but success still hinges on disciplined temperature management and machine maintenance.

By strategically matching the material and process to your specific demands, you can harness PTFE's powerful advantages while effectively managing its inherent limitations.

Summary Table:

| Disadvantage | Primary Mitigation Strategy | Key Consideration |

|---|---|---|

| Low Mechanical Strength & Creep | Use filled PTFE (e.g., glass, carbon) | Increases material cost, may reduce dielectric strength |

| High Thermal Expansion | Precise temperature control during processing | Requires disciplined operational protocols |

| Poor Abrasion Resistance | Use filled PTFE (e.g., graphite, bronze) | Can increase wear on machining tools |

| Complex & Costly Processing | Rigorous machine maintenance | Essential for preventing damage from soft PTFE |

Struggling with PTFE's limitations in your components? KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in both material science (including filled PTFE grades) and precision processing ensures your parts meet exacting demands for durability, dimensional stability, and chemical resistance. Whether you need prototypes or high-volume orders, we deliver solutions that balance performance with cost-effectiveness.

Contact KINTEK today to discuss your specific application and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers