To prevent rough edges when CNC turning Teflon, you must use exceptionally sharp cutting tools with a positive rake, apply generous amounts of coolant, and use high feed rates to minimize heat buildup. Because Teflon is soft and has poor thermal conductivity, heat concentrates at the cutting edge, causing the material to melt and tear rather than shear cleanly, which is the primary cause of burrs.

The core challenge with Teflon (PTFE) is not its hardness, but its tendency to deform and melt under pressure and heat. Your strategy must focus on shearing the material cleanly and evacuating heat as rapidly as possible, treating it fundamentally differently than metal.

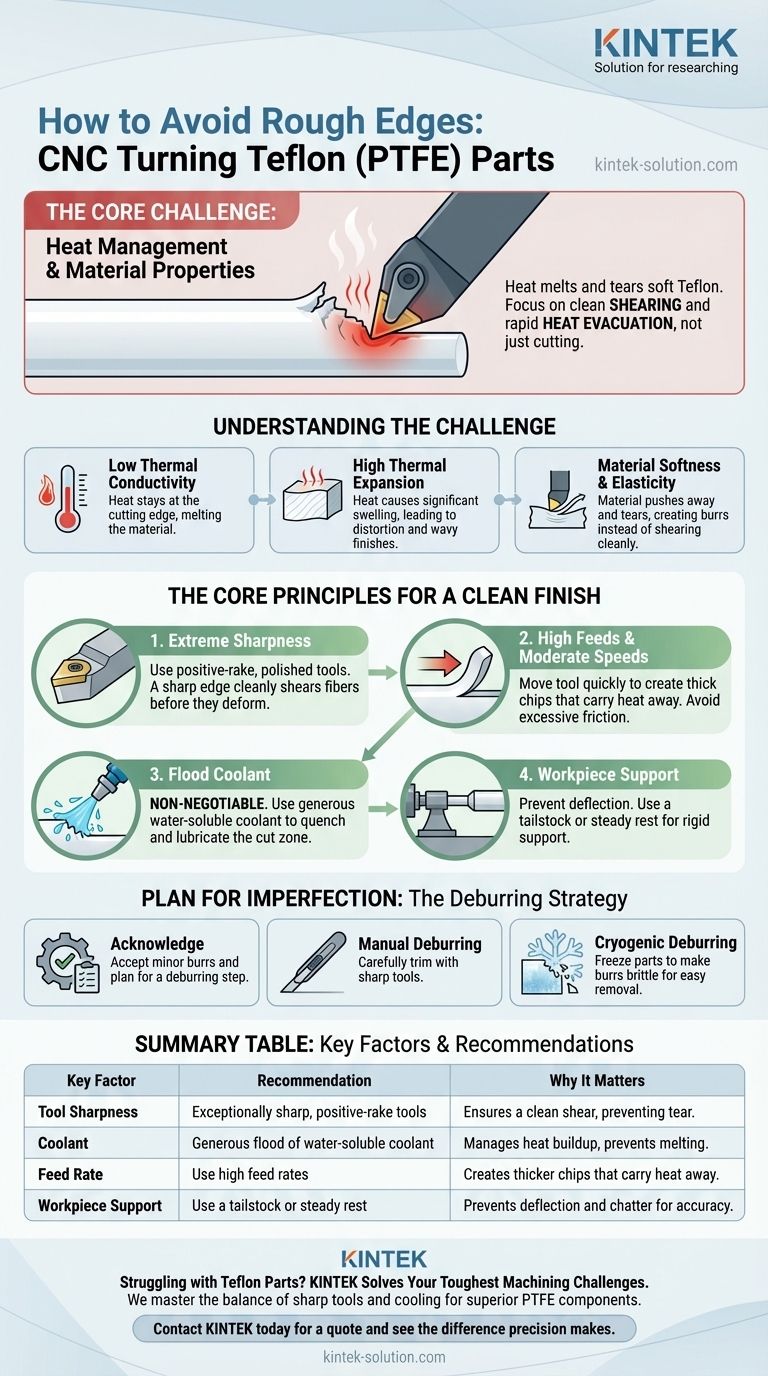

Understanding the Challenge: Why Teflon Creates Burrs

To machine Teflon effectively, you must first understand its unique properties. The material's softness, high thermal expansion, and low thermal conductivity combine to make it uniquely prone to developing rough edges and burrs.

Low Thermal Conductivity

Teflon is an excellent insulator, which means it doesn't transfer heat well. During machining, the friction-generated heat remains concentrated at the tool's cutting edge instead of dissipating through the workpiece. This localized heat quickly melts the material, causing it to smear rather than form a clean chip.

High Thermal Expansion

When that concentrated heat is applied, Teflon expands significantly. This causes the material to swell and distort during the cut, leading to dimensional inaccuracies and unpredictable engagement with the cutting tool, often resulting in a rough or wavy finish.

Material Softness and Elasticity

Unlike metals, which shear cleanly when a tool is applied, Teflon tends to push away, stretch, and tear. An even slightly dull tool will deform the material before it cuts, creating a raised burr or a frayed, fuzzy edge instead of a crisp corner.

The Core Principles for a Clean Finish

Achieving a smooth surface on turned Teflon parts requires a tactical approach that directly counters the material's properties. The focus is always on a clean shear and aggressive heat management.

Tooling is Paramount: Use Extreme Sharpness

Your cutting tool is the single most important factor. Use inserts specifically designed for plastics or aluminum, which have very sharp, polished cutting edges and a high positive rake angle. A sharp edge cleanly shears the polymer fibers before they have a chance to deform or tear.

Feeds and Speeds: Move Material Quickly

It may seem counterintuitive, but a high feed rate is often beneficial. A faster feed moves the tool through the material decisively, creating a thicker chip that carries heat away from the workpiece. Combine this with moderate surface speeds to prevent excessive frictional heat from building up in the first place.

The Role of Coolant: Flood the Cut Zone

Effective cooling is non-negotiable. Use a liberal flood of water-soluble coolant directed precisely at the cutting edge. The coolant serves two purposes: it lubricates the cut to reduce friction and, more critically, it immediately quenches the material to prevent melting and thermal expansion.

Workpiece Support: Prevent Deflection

Given its softness, long or thin Teflon workpieces will easily bend or deflect under tool pressure. This deflection leads to chatter, inconsistent cuts, and poor surface finish. Always use a tailstock or a steady rest to provide rigid support opposite the cutting tool.

Plan for Imperfection: The Deburring Strategy

Even with optimal technique, producing a completely burr-free Teflon part can be exceptionally difficult. A professional approach involves planning your deburring process from the start.

Acknowledge the Inevitable

Accept that minor burrs or a slightly raised edge are common outcomes. Designing the part with this in mind and incorporating a deburring step into your workflow saves time and reduces frustration.

Manual Deburring

The most common method is carefully trimming the burrs with a new, sharp utility knife or a specialized deburring tool. This requires a steady hand to avoid damaging the finished surface.

Advanced Technique: Cryogenic Deburring

For high-volume or high-precision parts, freezing the machined part is a highly effective technique. Lowering the temperature makes the Teflon brittle, allowing burrs to be snapped or vibrated off cleanly without affecting the part's final dimensions.

Making the Right Choice for Your Process

Your specific approach should be tailored to your primary objective, whether it's surface finish, dimensional tolerance, or production efficiency.

- If your primary focus is the best possible surface finish: Prioritize extremely sharp, positive-rake tooling and a high-volume flood of coolant aimed directly at the cut.

- If your primary focus is dimensional accuracy: Emphasize rigid workpiece support with a tailstock and use light, sharp finishing passes to minimize tool pressure and deflection.

- If your primary focus is production efficiency: Accept that minor burrs are likely and integrate a secondary deburring process, like manual trimming or cryogenic treatment, into your workflow.

By treating Teflon as a unique thermal and mechanical challenge, you can consistently produce clean, accurate, and functional components.

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Tool Sharpness | Exceptionally sharp, positive-rake tools | Ensures a clean shear, preventing material tear and deformation. |

| Coolant | Generous flood of water-soluble coolant | Manages heat buildup, the primary cause of melting and burrs. |

| Feed Rate | Use high feed rates | Creates thicker chips that carry heat away from the workpiece. |

| Workpiece Support | Use a tailstock or steady rest | Prevents deflection and chatter for consistent, accurate cuts. |

Struggling with Rough Teflon Parts? KINTEK Solves Your Toughest Machining Challenges

Producing clean, burr-free Teflon (PTFE) components requires specialized expertise and precision tooling. KINTEK manufactures high-performance PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We master the delicate balance of sharp tools, aggressive cooling, and optimal speeds to deliver superior finishes and tight tolerations.

Let us apply our expertise to your project. From custom prototypes to high-volume production, we ensure your PTFE parts are machined perfectly the first time.

Contact KINTEB today for a quote and see the difference precision makes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE and graphite packing compare in terms of corrosion resistance? Selecting the Right Material for Your Application

- Why is the PTFE ball valve considered a popular choice in various industries? Unmatched Reliability in Demanding Environments

- In which industries is porous PTFE applied? Solve Harsh Environment Challenges with KINTEK

- Why is PTFE's temperature stability important for sealing applications? Ensure Leak-Proof Performance from -200°C to 260°C

- What other specialized applications use PTFE lip seals? Ensure Reliability in Aerospace, Medical, and Automotive Systems

- What is the temperature range for virgin PTFE seals? Withstand -328°F to 500°F

- What are the high temperature capabilities of PTFE seals? Maximize Performance Up to 600°F (316°C)

- What makes PTFE gaskets and sheets ideal for chemical and pharmaceutical industries? Achieve Uncompromising Purity and Safety