To reduce burr formation when machining PTFE, you must use extremely sharp cutting tools with a positive rake, manage heat with appropriate speeds and coolant, and use light cutting pressures. Because PTFE is soft and deforms easily under heat and stress, the goal is to shear the material cleanly rather than push it out of the way.

The core challenge with PTFE is its tendency to deform and melt rather than chip like a metal. Preventing burrs requires shifting your mindset from aggressive material removal to a strategy of precise, low-stress slicing that respects the material's inherent softness and high thermal expansion.

Why PTFE Machining Demands a Unique Approach

Polytetrafluoroethylene (PTFE) is not a typical plastic. Its unique properties make it easy to cut but difficult to cut cleanly and accurately. Understanding these traits is the first step to eliminating burrs.

The Impact of Material Softness

PTFE has a low density and is exceptionally soft. A dull tool edge will not shear the material; it will simply push it, causing it to deform and stretch. This plastic deformation is the primary cause of burrs.

The Critical Role of Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among polymers. Even a small amount of heat generated from cutting friction will cause the material to expand significantly. This can lead to dimensional inaccuracies and cause the material to gum up on the tool, resulting in a poor finish.

The Challenge of Stress and Clamping

The material is susceptible to stress creep and deformation under pressure. Overtightening a vise or clamp will compress the part. When the cut is finished and the pressure is released, the material will spring back, ruining dimensional accuracy and often creating burrs at the edges.

A Technical Framework for Burr-Free PTFE Machining

Achieving a clean finish requires careful control over your tools, parameters, and workholding. Each element must be optimized to minimize heat and mechanical stress.

Tool Selection is Non-Negotiable

Your primary defense against burrs is the cutting tool itself. Use only exceptionally sharp, polished tools. A honed, mirror-finish edge slices through the material with minimal pressure.

HSS (High-Speed Steel) or uncoated carbide tools are effective. The geometry should have a high positive rake angle to promote a clean shearing action.

Calibrating Speeds and Feeds

You must balance speed to avoid two different problems. Too slow, and the tool may "plow" through the material; too fast, and you generate excessive heat that causes melting.

Maintain cutting speeds between 200 to 1000 m/min. For the best surface finish, use a slower feed rate to reduce cutting forces and improve control.

The Importance of Coolant

Applying a generous amount of coolant is crucial. Its primary job is not lubrication but heat evacuation. By keeping the workpiece and tool cool, you prevent thermal expansion and stop the PTFE from becoming gummy at the cutting point.

Depth of Cut and Chip Evacuation

Use a shallow depth of cut. A good rule is to not exceed one-third of the tool's diameter. This minimizes the cutting forces exerted on the material, reducing deformation.

Proper chip evacuation is also essential to prevent recutting, which generates more heat and mars the surface finish.

Common Pitfalls to Avoid

Even with the right setup, common mistakes can undermine your results. Being aware of them is critical for consistent success.

Overtightening the Workpiece

This is the most common source of dimensional errors. You must secure the part just enough to hold it for the cut. Applying excessive clamping pressure will deform the material, leading to an inaccurate part once it is released.

Ignoring Tool Wear

A sharp edge on a tool dulls quickly when cutting any material. With PTFE, even a slightly worn tool will begin to push material instead of cutting it. Inspect your tools frequently and replace or resharpen them at the first sign of wear.

Relying on Post-Processing

While techniques like bead blasting or micro-polishing can remove burrs after the fact, they should be considered a secondary step. Relying on them as a primary solution means your core machining process is not optimized, costing time and potentially affecting part tolerance.

Neglecting Safety

Fine PTFE dust can be generated during machining. It is a health hazard if inhaled. Always work in a well-ventilated area, use coolant to suppress dust, or wear an appropriate mask.

Making the Right Choice for Your Goal

Your specific strategy may change slightly depending on the final priority for the part.

- If your primary focus is the best possible surface finish: Prioritize extremely sharp, polished tools, use slower feed rates, and apply ample coolant.

- If your primary focus is holding the tightest tolerances: Concentrate on heat management with coolant and use the lightest possible clamping pressure to avoid part deformation.

- If your primary focus is a higher material removal rate: Use sharp carbide tools at the higher end of the recommended speed range, but be prepared for potential minor burrs that may require a finishing pass or light deburring.

Ultimately, mastering PTFE machining means treating it with precision and a light touch, ensuring every cut is a clean slice.

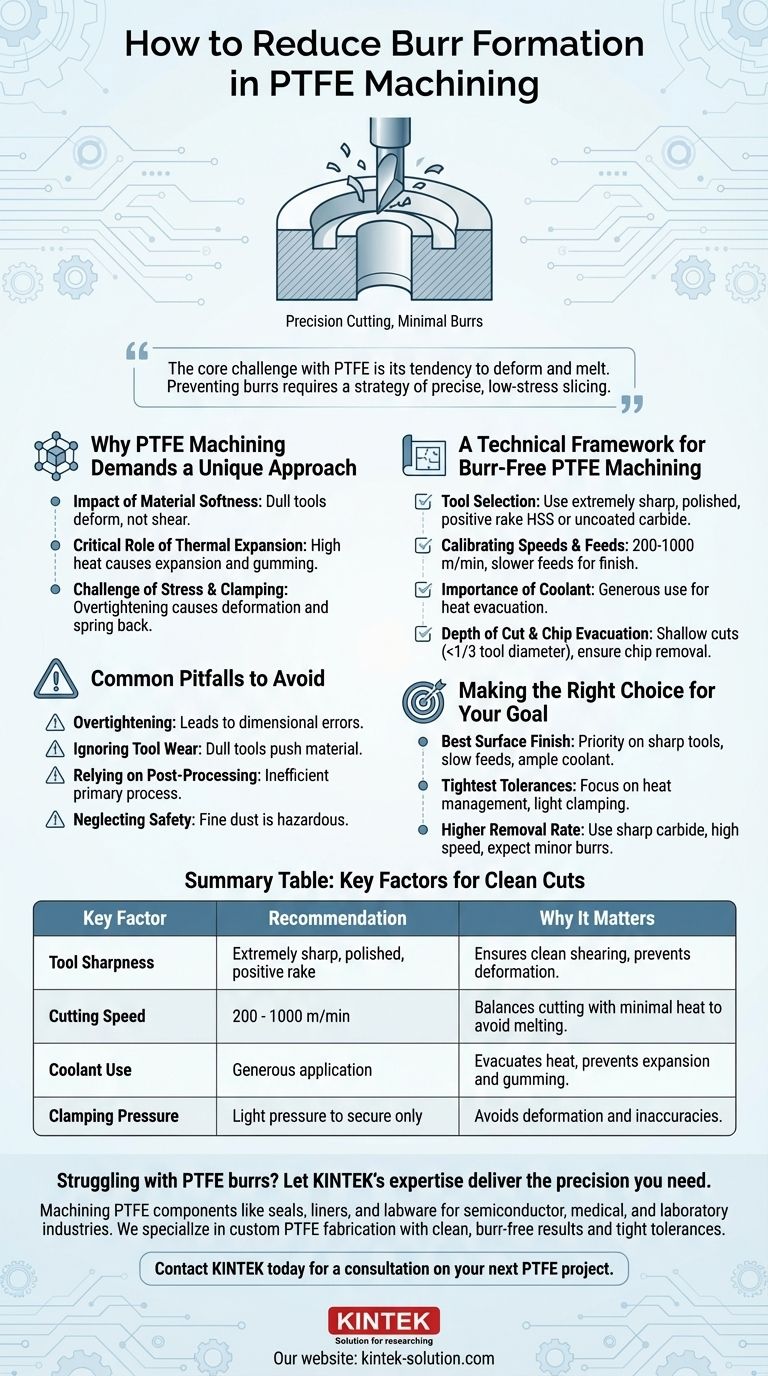

Summary Table:

| Key Factor | Recommendation | Why It Matters |

|---|---|---|

| Tool Sharpness | Extremely sharp, polished tools with a positive rake angle | Ensures clean shearing instead of pushing material, preventing deformation. |

| Cutting Speed | 200 - 1000 m/min | Balances efficient cutting with minimal heat generation to avoid melting. |

| Coolant Use | Generous application for heat evacuation | Prevents thermal expansion and material from becoming gummy. |

| Clamping Pressure | Light pressure to secure the part only | Avoids part deformation that leads to inaccuracies and burrs upon release. |

Struggling with PTFE burrs? Let KINTEK's expertise deliver the precision you need.

Machining PTFE components like seals, liners, and labware for the semiconductor, medical, and laboratory industries requires a deep understanding of the material's properties. At KINTEK, we specialize in custom PTFE fabrication, from prototypes to high-volume orders, using techniques that prioritize clean, burr-free results and tight tolerances.

Our team leverages sharp tooling, precise parameters, and meticulous heat management to ensure your parts meet the highest standards. Stop fighting burrs and start achieving reliable performance.

Contact KINTEK today for a consultation on your next PTFE project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do expanded PTFE (ePTFE) gaskets differ from other types? Solve Cold Flow & Seal Imperfect Flanges

- How does the PTFE layer enhance the functionality of elastomeric bearings? Achieve Superior Load Support and Movement

- What causes a PTFE butterfly valve to stick or become hard to operate? Diagnose and Fix Common Issues

- How can Teflon (PTFE) be processed into parts? A Guide to Compression Molding & CNC Machining

- What are the medical applications of expanded PTFE? The Key to Advanced Biocompatible Implants

- What are the primary challenges in molding PTFE? Overcome High Melt Viscosity and Sintering Complexities

- How do modern CNC machines contribute to energy efficiency in Teflon machining? Achieve Precision and Sustainability

- How does PTFE chevron packing accommodate pressure changes? Achieve a Self-Adjusting, Reliable Seal