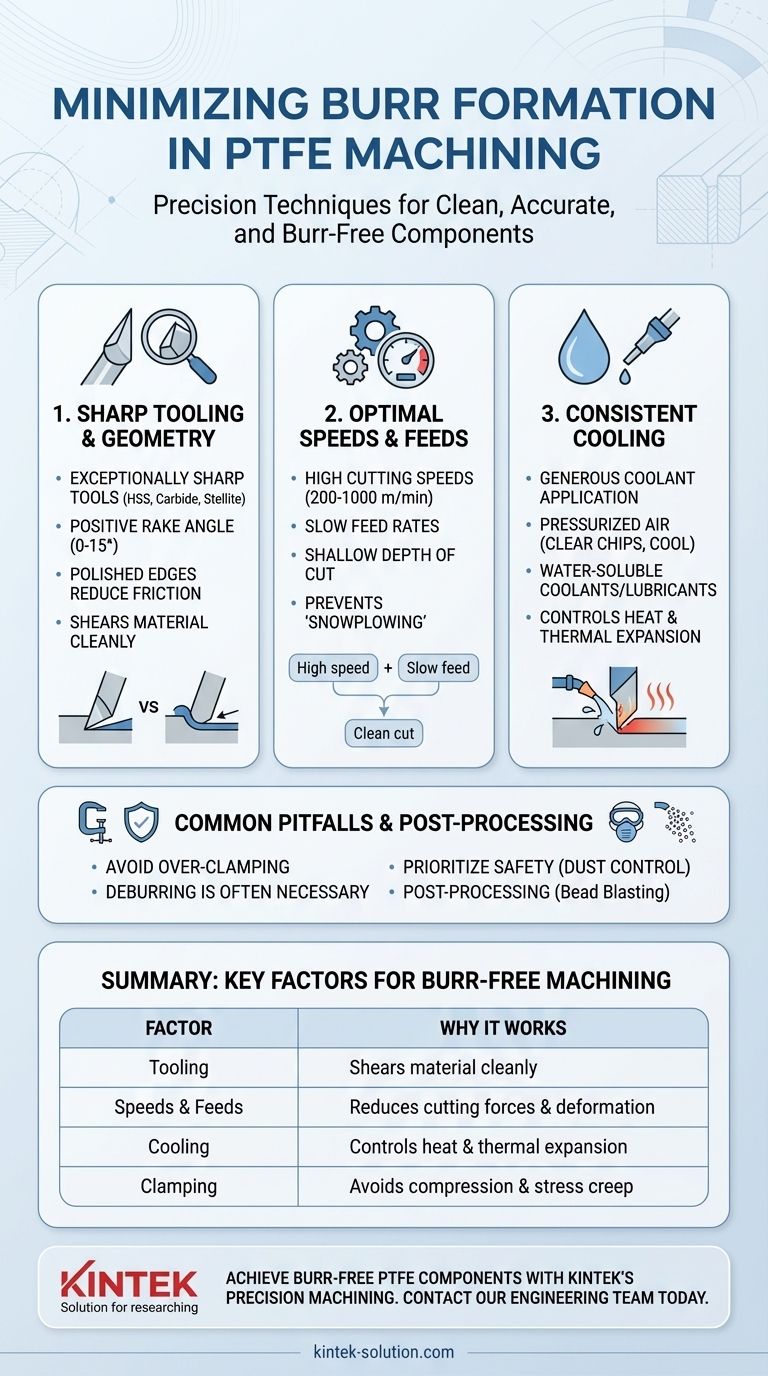

To effectively minimize burr formation in PTFE machining, you must use exceptionally sharp tools with a positive rake, employ high cutting speeds combined with slow feed rates, and apply consistent cooling. These three elements work together to shear the material cleanly rather than pushing or tearing it, which is the primary cause of burrs in this soft, "gummy" polymer.

The core challenge of machining PTFE is not its hardness, but its softness and high thermal expansion. Success depends less on aggressive material removal and more on a finesse-driven approach that respects the material's tendency to deform under pressure and heat.

Understanding PTFE's Unique Machining Challenges

Before applying specific techniques, it's crucial to understand why Polytetrafluoroethylene (PTFE) behaves differently from metals or even other plastics. Its properties are the root cause of common machining issues like burr formation.

The Problem of Softness and Deformation

PTFE is extremely soft and has a low modulus of elasticity. Instead of chipping away cleanly like a rigid material, it tends to push, stretch, and tear when a cutting tool is applied. This plastic deformation is what creates the fuzzy, difficult-to-remove burrs along the cut edge.

High Coefficient of Thermal Expansion

PTFE expands and contracts significantly with temperature changes. The friction from a cutting tool generates localized heat, causing the material to swell during the cut and then shrink as it cools. This thermal instability makes holding tight tolerances difficult and can worsen burring as the material deforms around the tool.

Stress Creep and Low Rigidity

This material is prone to "stress creep," meaning it will slowly deform over time when held under pressure. Excessive clamping force during setup can easily compress the part, leading to inaccurate dimensions and defects once the pressure is released.

Core Principles for Burr-Free Machining

Addressing PTFE's properties requires a specific and disciplined approach. Focusing on the following three areas will yield the most significant improvements in cut quality.

Tooling: Sharpness and Geometry are Paramount

The single most important factor is the cutting tool itself. A dull or improperly shaped tool will push material instead of shearing it.

Use tools made from High-Speed Steel (HSS) or carbide, with Stellite-tipped tools being another excellent option due to their wear resistance.

The cutting edge must be extremely sharp and polished, often referred to as "razor sharp." This reduces friction and promotes a clean shearing action.

Employ a positive top rake angle (typically 0–15 degrees). This geometry helps lift the chip away from the workpiece and significantly reduces cutting forces, minimizing material deformation.

Speeds and Feeds: A Counterintuitive Balance

The ideal combination for PTFE is a high cutting speed and a slow feed rate. This can seem counterintuitive but is essential for a clean cut.

High cutting speeds (200 to 1000 m/min) ensure the tool edge is moving fast enough to shear the material before it has time to deform.

Slow feed rates prevent the tool from pushing too much material at once, reducing pressure and friction. This gives the tool time to cut cleanly without "snowplowing" through the PTFE.

A shallow depth of cut is also recommended to further minimize cutting forces.

Thermal Management: The Role of Coolant

Controlling heat is non-negotiable for maintaining dimensional stability and reducing burrs.

Generous application of a coolant is critical. Pressurized air is often effective for clearing chips and providing some cooling without chemical interaction.

For more intensive operations, water-soluble coolants or lubricants are highly effective at dissipating heat and preventing the material from swelling.

Common Pitfalls and Post-Processing

Even with perfect technique, the nature of PTFE presents persistent challenges that require vigilance.

The Danger of Over-Clamping

Never use the same clamping pressure for PTFE as you would for metal. Use just enough force to secure the part. Over-tightening will compress the material, resulting in an inaccurate final part once it is released from the fixture.

The Inevitability of Deburring

While proper technique minimizes burrs, it may not eliminate them entirely. Plan for a deburring step. Sharp blades or specialized deburring tools can carefully remove remaining material. For a superior finish on a larger scale, post-processing methods like bead blasting can be effective.

A Critical Note on Safety

Machining PTFE creates fine dust particles that can be hazardous if inhaled. Always work in a well-ventilated area, use a coolant to suppress dust, and wear appropriate personal protective equipment, including a mask.

Making the Right Choice for Your Goal

Your primary objective should guide which aspect of the process you prioritize.

- If your primary focus is the absolute best surface finish: Prioritize razor-sharp, polished tools with a positive rake and very light, slow finishing passes.

- If your primary focus is maintaining tight dimensional tolerances: Concentrate on aggressive thermal management with constant coolant and meticulous control over clamping pressure.

- If your primary focus is production efficiency: Implement a strict tool maintenance schedule to ensure edges are re-sharpened or replaced regularly, preventing quality degradation over a run.

Ultimately, treating PTFE with precision and a deep understanding of its unique behavior is the key to achieving clean, accurate, and burr-free results.

Summary Table:

| Key Factor | Recommended Practice | Why It Works |

|---|---|---|

| Tooling | Razor-sharp, positive rake tools (HSS, carbide) | Shears material cleanly instead of pushing/tearing it |

| Speeds & Feeds | High cutting speed (200-1000 m/min), slow feed rate | Reduces cutting forces and material deformation |

| Cooling | Generous coolant or pressurized air application | Controls heat, prevents thermal expansion and swelling |

| Clamping | Minimal, gentle pressure | Avoids material compression and stress creep |

Achieve Burr-Free PTFE Components with KINTEK's Precision Machining

Struggling with burrs and dimensional instability in your PTFE parts? The techniques outlined above are core to our manufacturing process. At KINTEK, we specialize in machining high-precision PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, and industrial sectors.

We understand that your application demands flawless performance. Let us put our expertise to work for you:

- Guaranteed Precision: We utilize state-of-the-art equipment and strict protocols to ensure every part meets your exact specifications.

- Custom Fabrication: From rapid prototypes to high-volume production runs, we deliver consistent, burr-free quality.

- Material Expertise: We navigate PTFE's unique challenges so you don't have to, saving you time and ensuring part reliability.

Ready for superior PTFE components? Contact our engineering team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the limitations of PTFE-coated O-rings? Understand the risks of wear, flaking, and contamination.

- What materials are used in Teflon encapsulation for O-rings? A Guide to FEP & PFA Jackets

- How does PTFE Liner help in eliminating stick-slip in cable applications? Achieve Smooth, Reliable Motion

- What is the continuous operating temperature range for PTFE Teflon O-rings? Guide to -200°C to 260°C Performance

- What are the disadvantages of PTFE processing machines? High Costs, Material Weaknesses, and Production Challenges

- How should temperature-related seal performance issues be troubleshooted? A Step-by-Step Guide to Thermal Failure

- How do PTFE seals perform in dynamic and thermal cycling applications? Discover Unmatched Reliability for Demanding Conditions

- How do expanded PTFE (ePTFE) gaskets differ from other types? Solve Cold Flow & Seal Imperfect Flanges