In the automotive industry, Teflon bushings are strategically placed in high-friction, high-temperature areas like suspension systems, steering linkages, and engine components. Their primary purpose is to allow metal parts to move against each other with minimal resistance and without the need for traditional grease or oil, significantly reducing wear and improving performance.

The core value of Teflon bushings in a vehicle is not just reducing friction, but enabling the design of more durable, responsive, and maintenance-free mechanical systems by providing a self-lubricating, heat-resistant, and chemically inert surface.

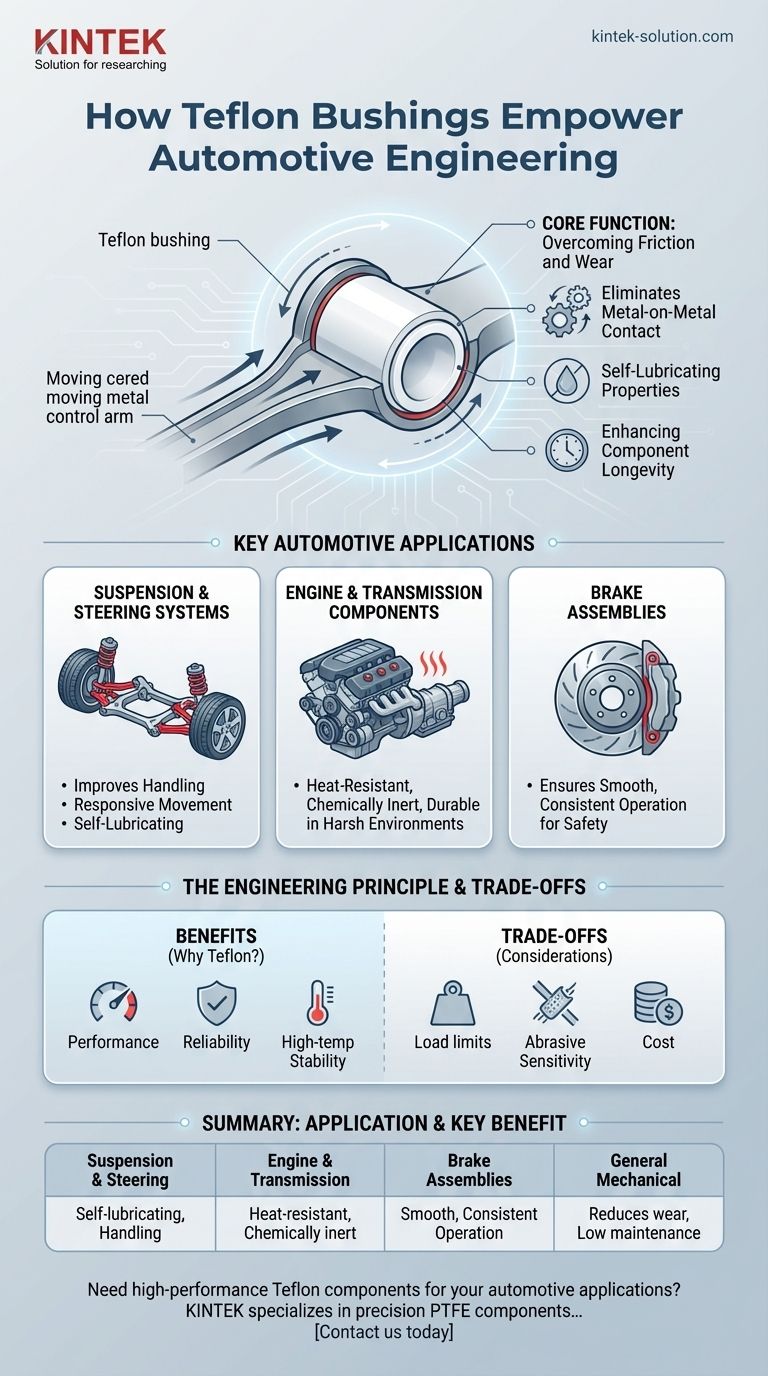

The Core Function: Overcoming Friction and Wear

At its heart, automotive engineering is a battle against friction, heat, and vibration. Teflon bushings are a critical tool in this battle, solving fundamental challenges that traditional materials cannot.

Eliminating Metal-on-Metal Contact

A bushing acts as a sacrificial sleeve or liner between two moving metal parts, such as a control arm and the vehicle's frame. By making this sleeve out of Teflon, engineers prevent the direct, high-friction contact that causes noise, vibration, and rapid wear.

Self-Lubricating Properties

The defining characteristic of Teflon (PTFE) is its extremely low coefficient of friction. This means it is inherently "slippery."

This self-lubricating nature eliminates the need for external oil or grease, which can dry out, attract dirt, or break down over time. This makes Teflon ideal for sealed components or areas that are difficult to service.

Enhancing Component Longevity

By drastically reducing friction and absorbing minor vibrations, Teflon bushings directly extend the service life of critical, and often expensive, automotive parts. Less wear means components maintain their precise tolerances for longer, ensuring consistent performance.

Key Automotive Applications

You will find Teflon bushings deployed in specific systems where their unique properties provide a clear engineering advantage over simpler materials like rubber or nylon.

In Suspension and Steering Systems

This is the most common application. Bushings are used in suspension control arms, sway bar mounts, and steering linkages.

Here, they allow for smooth, predictable movement as the wheels travel over bumps. Compared to soft rubber, Teflon provides a firmer connection, which can translate to more responsive and precise vehicle handling.

Within Engine and Transmission Components

Components inside or near the engine and transmission are exposed to intense heat and various fluids.

Teflon's thermal stability and chemical resistance make it a superior choice for bushings in these harsh environments, ensuring parts continue to move freely without degrading.

In Brake Assemblies

Even in brake systems, small bushings are used at pivot points for calipers or linkages. They ensure a smooth, consistent application and release of the brakes, which is critical for safety and performance.

Understanding the Trade-offs

While highly effective, Teflon bushings are not a universal solution. Their selection is a deliberate engineering decision based on a clear understanding of their limitations.

Load and Pressure Limitations

Teflon is not as strong as metal. In applications with extremely high compressive loads, a bronze or composite bushing may be chosen instead. Teflon excels in low-load, high-movement scenarios where friction is the primary concern.

Sensitivity to Abrasives

The low-friction surface of a Teflon bushing can be damaged by dirt, sand, and other abrasive contaminants. In very exposed or dirty environments, they must be properly sealed to maintain their effectiveness.

Cost vs. Other Materials

Teflon bushings are generally more expensive than their simple rubber or nylon counterparts. Their use is justified only when the benefits of self-lubrication, heat resistance, or improved performance outweigh the additional material cost.

The Engineering Principle: The Right Material for the Job

Choosing the right bushing material is about matching its properties to the specific demands of the application. Teflon is selected when its unique combination of benefits provides the most elegant and reliable solution.

- If your primary focus is performance and responsiveness: Teflon provides a stiffer, more direct connection in suspension systems compared to flexible rubber, enhancing handling.

- If your primary focus is reliability and low maintenance: Teflon's self-lubricating nature makes it ideal for sealed or hard-to-reach components that must last the vehicle's lifetime.

- If your primary focus is high-temperature operation: Teflon's thermal stability is its key advantage over other plastics or elastomers in engine and transmission applications.

Ultimately, the strategic use of Teflon bushings is a core principle of modern automotive design, trading brute strength for sophisticated, maintenance-free motion.

Summary Table:

| Application Area | Key Benefit of Teflon Bushings |

|---|---|

| Suspension & Steering | Self-lubricating, improves handling and responsiveness |

| Engine & Transmission | Heat-resistant, chemically inert for harsh environments |

| Brake Assemblies | Ensures smooth, consistent operation for safety |

| General Mechanical Systems | Reduces wear, eliminates need for grease, lowers maintenance |

Need high-performance Teflon components for your automotive applications? KINTEK specializes in manufacturing precision PTFE components, including custom bushings, seals, and liners. We serve the automotive, semiconductor, medical, and industrial sectors with custom fabrication from prototypes to high-volume orders. Our expertise ensures you get durable, reliable parts designed for superior performance and longevity. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining