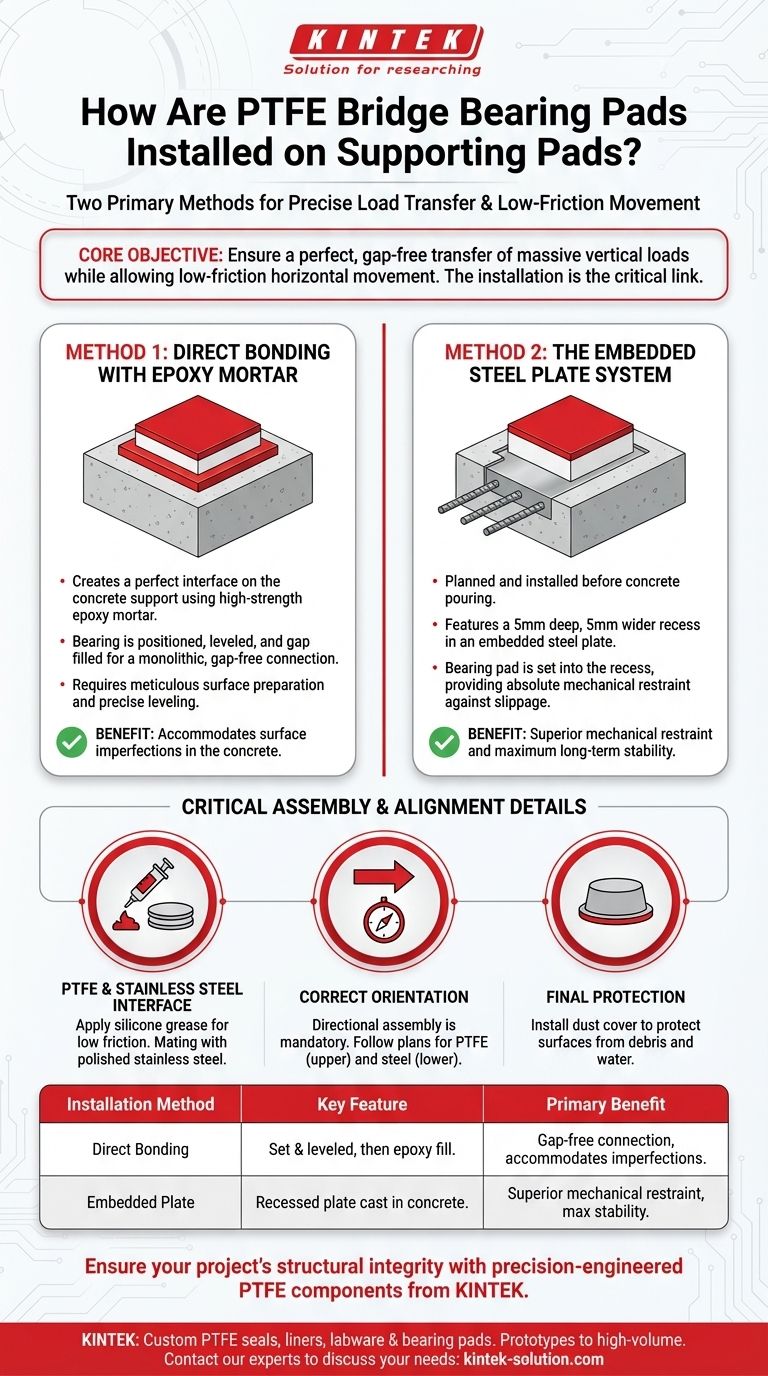

There are two primary methods for installing PTFE bridge bearing pads onto their supporting pads or pier caps. The choice depends on project specifications and the desired level of mechanical restraint, with one method involving direct bonding with epoxy mortar and the other using a recessed, embedded steel plate. Both methods aim to create a perfectly level and stable base for the bearing.

The core objective of any installation method is to ensure a perfect, gap-free transfer of massive vertical loads from the bearing to the substructure while allowing for the low-friction horizontal movement the PTFE surface is designed to provide. The installation is not merely placement; it is the critical link that makes the entire bearing system function correctly.

Understanding the Installation Goal

Before examining the methods, it's essential to understand the engineering principles at play. An improper installation can lead to stress concentrations, premature failure, and compromised structural integrity.

The Need for a Perfect Surface

The entire surface of the bearing's bottom plate must be in uniform contact with the supporting structure, typically a concrete pier cap or abutment.

Any voids, gaps, or high spots will create uneven pressure. This can damage both the bearing and the concrete support over time.

Ensuring Absolute Stability

The bearing must be perfectly stable and unable to shift or "walk" from its designated position. Its only intended movement is the sliding of the PTFE surface against the mating stainless steel plate.

The Two Core Installation Methods

The method chosen is a critical design decision that impacts the construction process and the long-term performance of the bearing.

Method 1: Direct Bonding with Epoxy Mortar

This method involves creating a perfect interface directly on the concrete support using a high-strength epoxy mortar.

The bearing is carefully positioned and leveled on the supporting pad. The gap is then filled with the epoxy, which bonds the bearing's bottom plate to the structure. This ensures a monolithic, gap-free connection that perfectly distributes the load.

This approach demands meticulous surface preparation and precise leveling to be effective.

Method 2: The Embedded Steel Plate System

This is a more robust, mechanically fixed approach that is planned before the concrete for the supporting pad is poured.

An embedded steel plate is positioned on the support and connected to the internal steel reinforcement mesh. This plate features a shallow recess, typically 5mm deep and 5mm wider than the bearing pad's dimensions.

The bearing pad is then set into this recess. The recess provides absolute mechanical restraint against any lateral slippage, ensuring the bearing remains precisely where it was designed to be.

Critical Assembly and Alignment Details

Beyond securing the base, the correct assembly of the bearing's components is fundamental to its function. These steps are non-negotiable for a successful installation.

The PTFE and Stainless Steel Interface

PTFE bearing pads are part of a system. The PTFE surface is designed to slide against a mating polished stainless steel plate.

A layer of silicone grease must be applied evenly between the PTFE and the stainless steel plate. This lubricant is essential to achieve the extremely low coefficient of friction required for thermal expansion and contraction.

Correct Orientation is Mandatory

The bearing assembly is directional. The PTFE board is part of the upper assembly that moves with the bridge superstructure, while the stainless steel plate is typically fixed to the substructure (the pier).

Furthermore, guide plates or stop plates dictate the direction of movement. The installation must strictly follow the direction indicated on the plans and the bearing itself.

Final Protection

Once the installation and alignment are complete, a dust cover must be installed. This flexible seal protects the sliding surfaces from water, dirt, and debris, which could increase friction, score the surfaces, and impede the bearing's function.

Making the Right Choice for Your Project

The selection between direct bonding and an embedded plate is an engineering decision based on load, expected movement, and construction tolerances.

- If your primary focus is maximum long-term stability: The embedded steel plate system offers superior mechanical restraint and is generally the more robust engineering solution.

- If your primary focus is accommodating slight imperfections in the concrete surface: The direct bonding method with epoxy mortar provides an effective way to create a perfectly level and fully supported base on-site.

Ultimately, a successful installation transforms the bearing from a component into an integral, functional part of the bridge structure.

Summary Table:

| Installation Method | Key Feature | Primary Benefit |

|---|---|---|

| Direct Bonding with Epoxy Mortar | Bearing is set and leveled, then gap is filled with high-strength epoxy. | Creates a monolithic, gap-free connection; ideal for accommodating surface imperfections. |

| Embedded Steel Plate System | A recessed steel plate is cast into the concrete support before pouring. | Provides superior mechanical restraint against lateral movement; offers maximum long-term stability. |

Ensure your project's structural integrity with precision-engineered PTFE components from KINTEK.

Whether you're working on a bridge, a medical device, or a specialized industrial application, the correct installation and performance of PTFE parts are critical. KINTEK specializes in manufacturing high-quality, custom PTFE components—including seals, liners, labware, and bearing pads—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring every part meets your exact specifications for precision and durability.

Ready to discuss your project's specific needs? Contact our experts today to learn how KINTEK's solutions can bring reliability and performance to your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments