In short, glass-filled PTFE rods are machined into critical components for the automotive industry where a unique combination of low friction, high mechanical strength, and resistance to heat and chemicals is required. They are most commonly found in high-load, high-wear applications such as suspension bushings, thrust washers, guide strips, and high-performance seals for engines and transmissions.

The core reason for its use is that adding glass fibers to Polytetrafluoroethylene (PTFE) transforms a soft, slippery material into a robust engineering plastic. This composite material solves the critical automotive challenges of reducing wear, withstanding heavy loads, and resisting aggressive fluids and high temperatures.

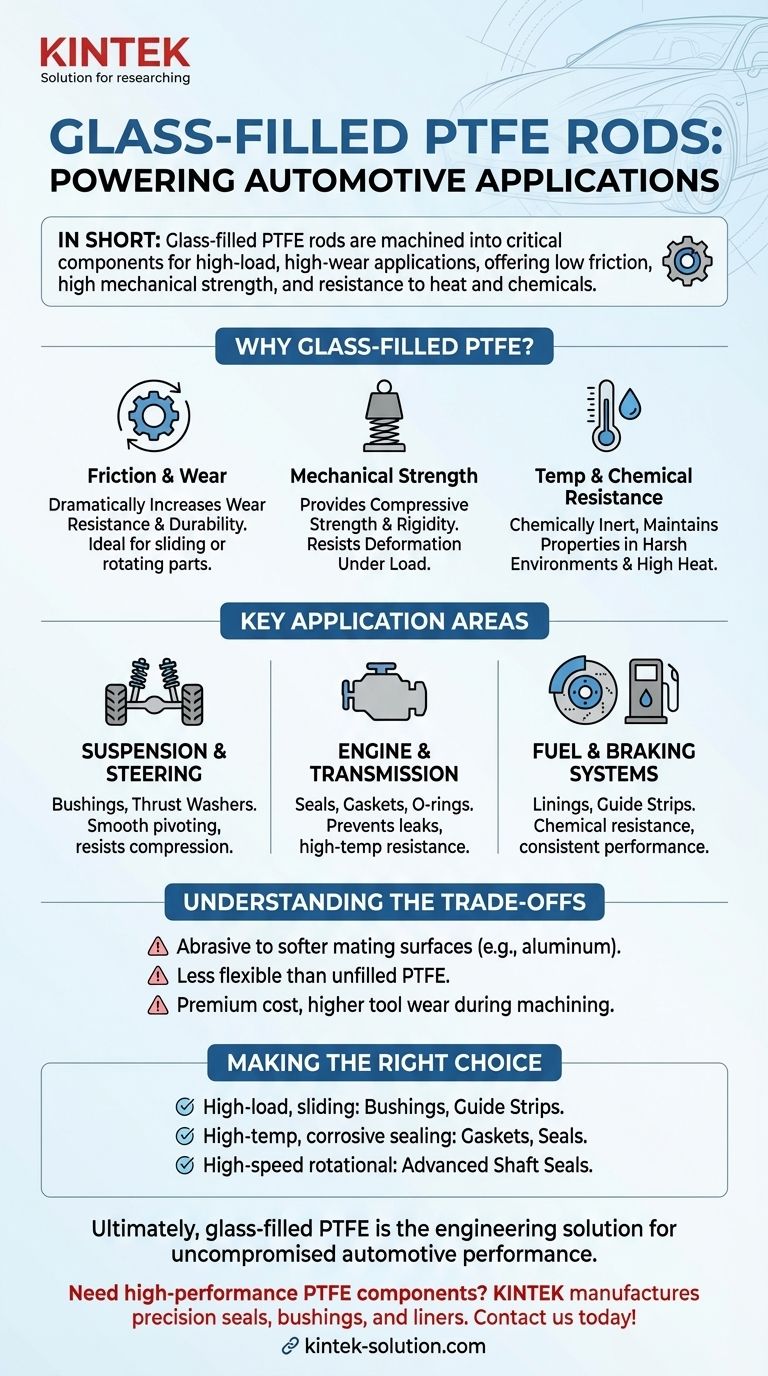

Why Glass-Filled PTFE is a Go-To Automotive Material

Automotive engineers face a constant battle against friction, heat, chemical corrosion, and mechanical stress. Glass-filled PTFE provides a unique solution that addresses all of these challenges simultaneously, making it invaluable for improving reliability and performance.

Solves the Friction and Wear Problem

Pure PTFE is famous for its extremely low coefficient of friction. However, it is relatively soft and can wear quickly under abrasive conditions.

The addition of glass fibers dramatically increases the material's wear resistance and durability. This makes it ideal for parts that slide or rotate under pressure, minimizing energy loss and extending the component's lifespan.

Unmatched Mechanical Strength Under Load

Standard PTFE can deform or "creep" when subjected to a constant heavy load, especially at elevated temperatures. This is unacceptable for precision components.

Glass reinforcement provides significant compressive strength and rigidity. This ensures the material holds its shape and dimensions, making it perfect for suspension bushings and thrust washers that bear the vehicle's weight and absorb dynamic forces.

Superior Resistance to Temperature and Chemicals

Vehicle engine bays and drivetrains are harsh environments, with high operating temperatures and exposure to corrosive fuels, oils, and lubricants.

PTFE is almost completely chemically inert and maintains its properties across a wide temperature range. This allows it to function flawlessly as seals, gaskets, and linings in direct contact with these aggressive fluids without degrading.

Key Application Areas in Detail

Glass-filled PTFE's properties make it suitable for several critical systems within a vehicle, from the chassis to the engine.

In Suspension and Steering Systems

Components in these systems must endure constant movement and heavy loads.

Glass-filled PTFE is machined into bushings and thrust washers that allow suspension components to pivot smoothly while resisting wear and compression, contributing to stable handling and longevity.

In Engine and Transmission Systems

This is where the material's resistance to heat and chemicals truly shines.

It is used for valve stem seals, shaft seals, gaskets, and O-rings. These parts prevent leaks of oil and other fluids at high temperatures, ensuring the engine and transmission operate efficiently and reliably. Its use in high-performance lip seals for EV e-drives and NASCAR engine shafts highlights its capability in extreme conditions.

In Fuel and Braking Systems

Reliability and chemical resistance are non-negotiable in these safety-critical systems.

The material serves as linings for fuel hoses, preventing degradation from aggressive modern fuel blends. In braking systems, its low friction and heat resistance are leveraged for components like guide strips that must perform consistently under severe conditions.

Understanding the Trade-offs

While highly effective, glass-filled PTFE is not a universal solution. An objective assessment requires acknowledging its specific characteristics.

Impact on Mating Surfaces

The glass fibers that provide excellent wear resistance for the PTFE part can be more abrasive to softer mating surfaces, such as aluminum or brass. Proper pairing with hardened or coated metal surfaces is a key design consideration.

Reduced Flexibility

Compared to unfilled PTFE, the glass-filled variant is more rigid and less flexible. This makes it less suitable for applications requiring high conformity or dynamic sealing against irregular surfaces.

Machinability and Cost

Glass-filled PTFE is a premium performance material, which is reflected in its cost. The abrasive nature of the glass filler also causes more rapid tool wear during machining compared to unfilled plastics, which can influence manufacturing costs.

Making the Right Choice for Your Application

Selecting the correct material is about matching its properties to the specific engineering problem you need to solve.

- If your primary focus is reducing friction in high-load, sliding parts: Glass-filled PTFE is the definitive choice for bushings, guide strips, and thrust washers.

- If your primary focus is reliable sealing in high-temperature, corrosive environments: This material is ideal for engine gaskets, valve stem seals, and fuel system components.

- If your primary focus is performance in high-speed rotational applications: Its stability and low wear make it essential for advanced shaft seals in EV drivetrains and performance engines.

Ultimately, glass-filled PTFE is the engineering solution for automotive applications where performance and reliability cannot be compromised.

Summary Table:

| Application Area | Key Components | Primary Benefits |

|---|---|---|

| Suspension & Steering | Bushings, Thrust Washers | High wear resistance, handles heavy loads |

| Engine & Transmission | Seals, Gaskets, O-rings | Resists heat, chemicals, and high temperatures |

| Fuel & Braking Systems | Linings, Guide Strips | Chemical inertness, reliable performance |

Need high-performance PTFE components for your automotive application? KINTEK manufactures precision glass-filled PTFE seals, bushings, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for durability and reliability. Contact us today to discuss your project and see how we can enhance your product's performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the potential issues of not using a Teflon sheet with a heat press? Protect Your Equipment & Projects

- How do the non-stick properties of PTFE benefit sealing technology? Enhance Seal Life and Purity

- What is the purpose of a PTFE Expansion Bellow in piping systems? Protect Your System from Stress and Failure

- What types of fluids can PTFE control valves handle? Master Corrosive Chemicals with Confidence

- What industries benefit from the chemical resistance of PTFE lined butterfly valves? Key Applications & Selection Guide

- What are the main applications of PTFE lined ball valves? Control Corrosive & High-Purity Fluids Safely

- In which industries are PTFE lined ball valves commonly used? Master Corrosive & High-Purity Fluid Control

- What are the uses of Micro Powder PTFE? The Ultimate Additive for Friction & Wear Reduction