When food manufacturers prioritize both safety and productivity, Teflon sheets emerge as a critical solution. These high-performance materials prevent contamination, streamline operations, and withstand extreme conditions—all while meeting strict FDA and EU compliance standards. Here’s how they transform industrial food processing.

Teflon Sheets in Food Processing: Balancing Safety and Performance

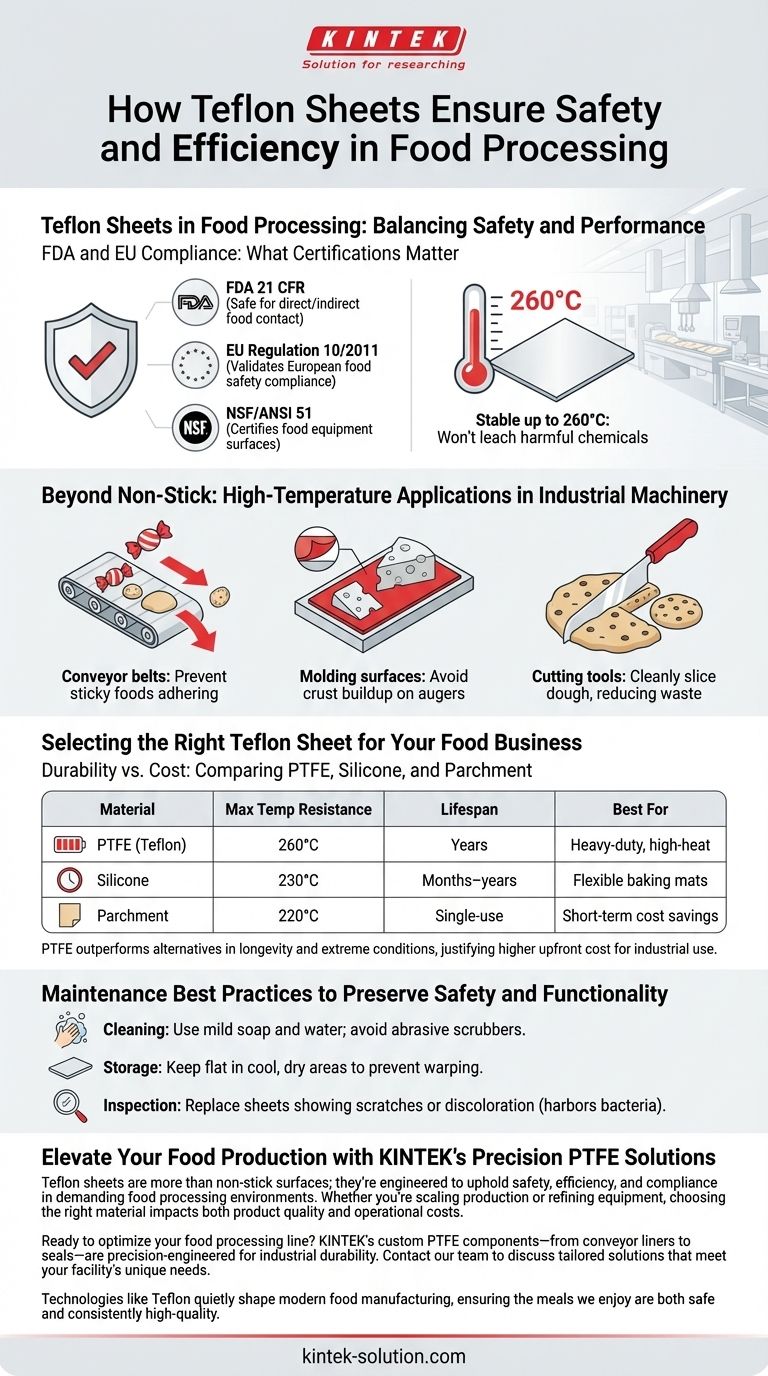

FDA and EU Compliance: What Certifications Matter

Food-grade Teflon sheets must adhere to rigorous safety benchmarks. Key certifications include:

- FDA 21 CFR: Ensures materials are safe for direct/indirect food contact.

- EU Regulation 10/2011: Validates compliance with European food safety standards.

- NSF/ANSI 51: Certifies suitability for food equipment surfaces.

These standards guarantee that Teflon sheets won’t leach harmful chemicals, even under high heat. For instance, research shows they remain stable up to 260°C—well beyond typical baking or frying temperatures.

Beyond Non-Stick: High-Temperature Applications in Industrial Machinery

Teflon’s heat resistance extends to industrial-scale equipment:

- Conveyor belts: Prevent sticky foods (e.g., candies, dough) from adhering during transport.

- Molding surfaces: Used in cheese production to avoid crust buildup on augers.

- Cutting tools: Coated piano wires slice cookie dough cleanly, reducing waste.

Aerospace and automotive industries leverage similar properties for extreme environments, proving Teflon’s versatility.

Selecting the Right Teflon Sheet for Your Food Business

Durability vs. Cost: Comparing PTFE, Silicone, and Parchment

| Material | Max Temp Resistance | Lifespan | Best For |

|---|---|---|---|

| PTFE (Teflon) | 260°C | Years | Heavy-duty, high-heat |

| Silicone | 230°C | Months–years | Flexible baking mats |

| Parchment | 220°C | Single-use | Short-term cost savings |

PTFE outperforms alternatives in longevity and extreme conditions, justifying its higher upfront cost for industrial use.

Maintenance Best Practices to Preserve Safety and Functionality

- Cleaning: Use mild soap and water; avoid abrasive scrubbers.

- Storage: Keep flat in cool, dry areas to prevent warping.

- Inspection: Replace sheets showing scratches or discoloration, as damage can harbor bacteria.

For tough residues, well-ventilated solvent use is occasionally acceptable—but routine gentle cleaning extends sheet life.

Elevate Your Food Production with KINTEK’s Precision PTFE Solutions

Teflon sheets are more than non-stick surfaces; they’re engineered to uphold safety, efficiency, and compliance in demanding food processing environments. Whether you’re scaling production or refining equipment, choosing the right material impacts both product quality and operational costs.

Ready to optimize your food processing line? KINTEK’s custom PTFE components—from conveyor liners to seals—are precision-engineered for industrial durability. [Contact our team] to discuss tailored solutions that meet your facility’s unique needs.

Technologies like Teflon quietly shape modern food manufacturing, ensuring the meals we enjoy are both safe and consistently high-quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

Related Articles

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense