At its core, Teflon packing is popular in demanding environments because its fundamental chemical structure makes it exceptionally resilient. It is almost universally inert, meaning it does not react with or degrade when exposed to harsh chemicals, and it maintains its integrity across a significant range of temperatures.

The decision to use Teflon packing is a strategic choice for reliability. Its unique combination of chemical inertness, low friction, and thermal stability prevents equipment failure, reduces maintenance, and protects product purity in critical applications.

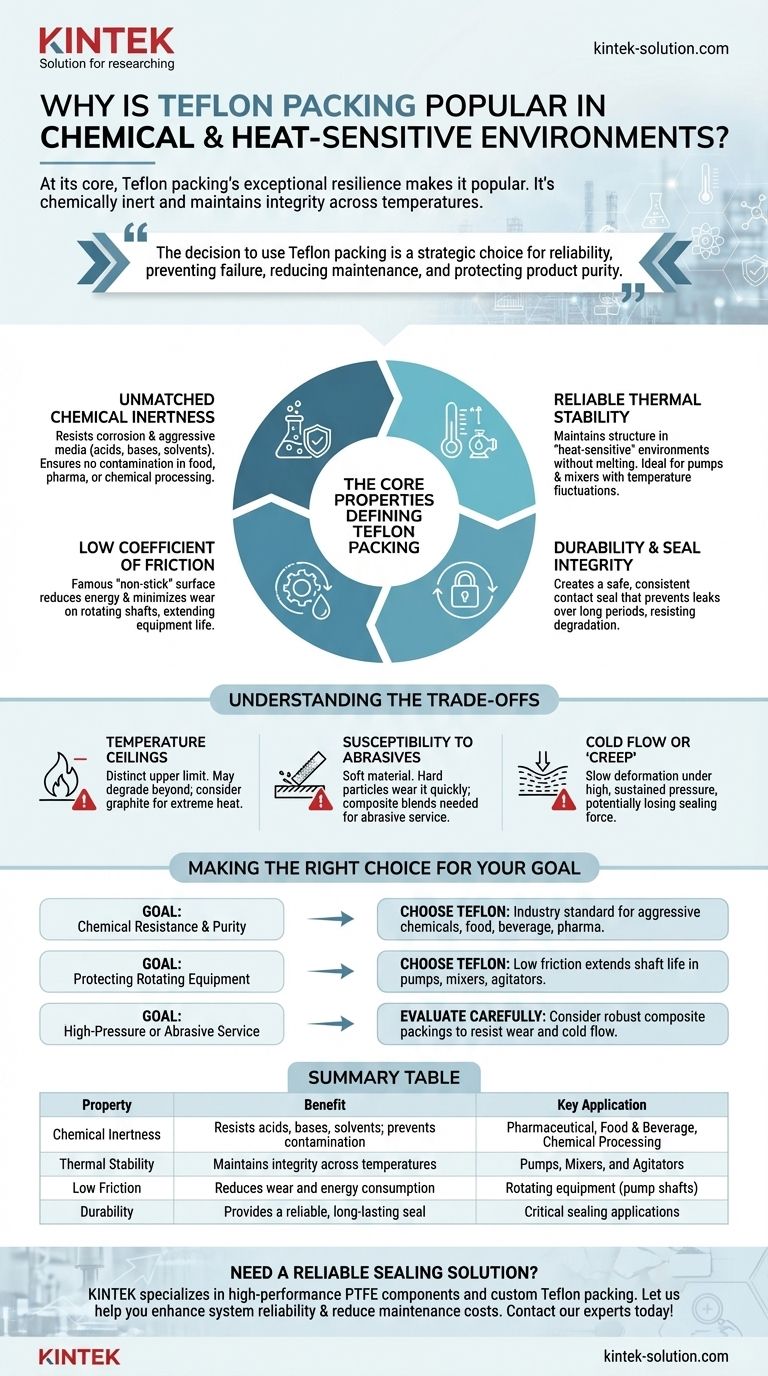

The Core Properties Defining Teflon Packing

The effectiveness of Teflon, or Polytetrafluoroethylene (PTFE), is not a single feature but a combination of inherent material properties. Understanding these attributes explains why it is a default choice for many engineers.

Unmatched Chemical Inertness

Teflon packing is renowned for its resistance to corrosion and chemical attack. It can handle a vast spectrum of aggressive media, including strong acids, bases, and solvents, without degrading.

This inertness is critical in applications where contamination is unacceptable. In food, beverage, or pharmaceutical processing, Teflon ensures that no material from the seal leaches into or discolors the product.

Reliable Thermal Stability

While not suitable for extreme high-temperature applications like graphite, Teflon performs reliably in what are considered "heat-sensitive" environments for many other polymers. It maintains its structure and sealing capability without melting or breaking down.

This stability ensures a consistent seal in equipment that experiences temperature fluctuations during operation, such as pumps or mixers handling warm fluids.

Low Coefficient of Friction

Teflon is famous for its "non-stick" surface, which translates to an extremely low coefficient of friction. When used as packing around a rotating shaft in a pump or agitator, this property is invaluable.

The low friction reduces the energy required to turn the shaft and, more importantly, minimizes wear on the equipment itself. This leads to longer service life for both the packing and the machinery, directly lowering maintenance costs.

Durability and Seal Integrity

These properties combine to create a durable and reliable seal. Because the material doesn't degrade from chemical exposure or stick to moving parts, it forms a safe, consistent contact seal that prevents leaks over long periods.

Understanding the Trade-offs

No material is perfect for every situation. While Teflon is incredibly versatile, its limitations are just as important to understand for proper application.

Temperature Ceilings

Teflon has a distinct upper-temperature limit. Beyond this point, it can begin to degrade or lose its mechanical properties. For applications involving extreme heat, materials like graphite or specialized composite packings may be a more appropriate choice.

Susceptibility to Abrasives

Teflon is a relatively soft material. If the fluid being sealed contains hard, abrasive particles (like in a slurry), the packing can wear away quickly. In these abrasive service conditions, a harder packing material or a composite blend is often required to ensure a reasonable service life.

Cold Flow or "Creep"

Under high, sustained pressure, Teflon can exhibit a phenomenon known as "cold flow" or creep, where the material slowly deforms over time. In very high-pressure static sealing applications, this can eventually lead to a loss of sealing force and potential leaks.

Making the Right Choice for Your Goal

Selecting the correct packing material is crucial for system reliability and safety. Your primary operational goal should guide your decision.

- If your primary focus is chemical resistance and product purity: Teflon is the industry standard for handling aggressive chemicals or for use in food, beverage, and pharmaceutical applications.

- If your primary focus is protecting rotating equipment: Teflon's low friction is a significant advantage for reducing wear on shafts in pumps, mixers, and agitators, extending equipment life.

- If your primary focus is high-pressure or abrasive service: Carefully evaluate if pure Teflon is sufficient, and consider more robust composite packings designed to resist wear and cold flow.

Understanding Teflon's distinct strengths and limitations empowers you to design and maintain more reliable and efficient systems.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents contamination | Pharmaceutical, Food & Beverage, Chemical Processing |

| Thermal Stability | Maintains integrity across a wide temperature range | Pumps, Mixers, and Agitators with temperature fluctuations |

| Low Friction | Reduces equipment wear and energy consumption | Rotating equipment like pump shafts |

| Durability | Provides a reliable, long-lasting seal | Critical sealing applications requiring minimal maintenance |

Need a reliable sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom Teflon packing. Our expertise ensures you get a seal that delivers:

- Maximum Chemical Resistance: Protect your product purity and process integrity.

- Superior Performance: Benefit from low friction and thermal stability to extend equipment life.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions for the semiconductor, medical, laboratory, and industrial industries.

Let us help you enhance system reliability and reduce maintenance costs. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability

- What machining processes are used to create Teflon parts? Achieve Precision with Expert PTFE Machining

- What are PTFE rotary lip seals and what applications are they used for? High-Performance Sealing Solutions

- How does the PTFE oil seal's design handle shaft eccentricity? Achieve Reliable Sealing Under Dynamic Conditions

- In which industries are PTFE oil seals commonly used? Ensuring Reliability in Extreme Conditions

- What are the key differences between PTFE and EPDM valve seats? Choose the Right Material for Your Application

- In which applications are PTFE seals commonly used at high temperatures? Solve HPHT Sealing Challenges

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance