In short, maintaining an effective cooling system is critical when machining PTFE because the material is highly sensitive to heat. Without proper thermal management, the friction from the cutting tool rapidly generates heat, causing significant thermal expansion. This leads directly to part warping, poor dimensional accuracy, and a rough surface finish.

The core challenge of machining PTFE is not its softness, but its thermal instability. An effective cooling system is the primary strategy to counteract its high coefficient of thermal expansion, ensuring the final part meets its required dimensional specifications.

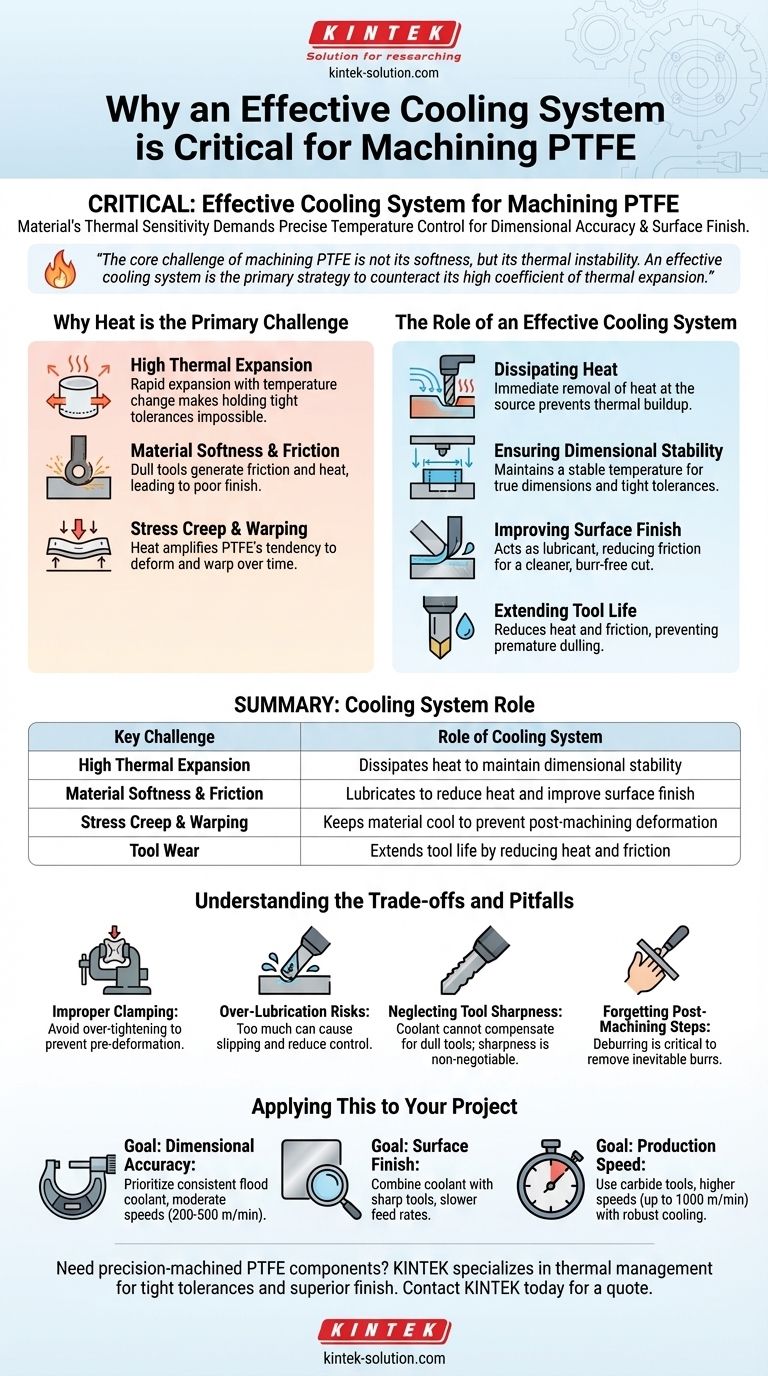

Why Heat is the Primary Challenge with PTFE

To understand the need for cooling, we must first understand the material's inherent properties. Unlike metals or harder plastics, PTFE's biggest machining challenges stem from its unique response to temperature and pressure.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes far more than most other engineering materials. Even a minor increase in heat at the cutting interface can cause the part to grow, making it impossible to hold tight tolerances.

Material Softness and Friction

While PTFE's softness makes it easy to cut, it can also lead to high friction. A less-than-perfectly-sharp tool will tend to push or "plow" the material rather than shearing it cleanly, generating excessive heat and a poor finish.

Stress Creep and Warping

PTFE has a tendency to "creep," or slowly deform under sustained pressure. This effect is significantly amplified by heat, which relaxes the material and can cause a finished part to warp or change shape after machining.

The Role of an Effective Cooling System

A constant flow of coolant serves multiple purposes, all aimed at counteracting the material's natural tendencies and maintaining control over the machining process.

Dissipating Heat at the Source

The most important function of a coolant is to remove heat from the tool and workpiece as it is being generated. This immediate action prevents heat from building up and causing thermal expansion.

Ensuring Dimensional Stability

By keeping the part at a stable, cool temperature, the coolant ensures that the dimensions you are cutting are the true dimensions of the final product. This is the key to achieving and maintaining tight tolerances.

Improving Surface Finish

Coolant acts as a lubricant, reducing friction between the tool and the material. This promotes a cleaner shearing action, which minimizes the rough surfaces and burrs that are common when machining soft materials like PTFE.

Extending Tool Life

By reducing heat and friction, the coolant also prevents the cutting edge of the tool from dulling prematurely, leading to more consistent results over longer production runs.

Understanding the Trade-offs and Pitfalls

Effective thermal management is more than just applying coolant. A successful outcome requires a holistic approach that accounts for other variables.

Improper Clamping Pressure

Because PTFE is soft and prone to stress creep, over-tightening the part in a vise or fixture is a common mistake. This can compress or deform the material before a cut is even made, making dimensional accuracy impossible.

Over-Lubrication Risks

While some lubrication helps, an excessive amount of lubricant can be counterproductive. It can cause the tool to slip or make it difficult to maintain precise control, especially during delicate finishing operations.

Neglecting Tool Sharpness

Coolant cannot compensate for a dull tool. A sharp, polished cutting tool made from High-Speed Steel (HSS) or carbide is non-negotiable, as it cuts with minimal friction and heat generation.

Forgetting Post-Machining Steps

Even with optimal cooling and tooling, PTFE's softness means burrs are almost inevitable. Deburring is a critical final step to remove sharp edges that can cause issues during assembly or lead to premature part failure.

Applying This to Your Project

Use your primary goal to determine your focus.

- If your primary focus is dimensional accuracy: Prioritize a consistent flood coolant system and use moderate cutting speeds (200-500 m/min) to eliminate thermal expansion.

- If your primary focus is surface finish: Combine coolant with extremely sharp, polished cutting tools and slower feed rates to ensure a clean shearing action that minimizes material tearing.

- If your primary focus is production speed: Use carbide-tipped tools at the higher end of the recommended speed range (up to 1000 m/min), but ensure your cooling system is robust enough to handle the increased heat load.

Ultimately, mastering PTFE machining means respecting its thermal properties and using cooling as your primary tool for control.

Summary Table:

| Key Challenge | Role of Cooling System |

|---|---|

| High Thermal Expansion | Dissipates heat to maintain dimensional stability |

| Material Softness & Friction | Lubricates to reduce heat and improve surface finish |

| Stress Creep & Warping | Keeps material cool to prevent post-machining deformation |

| Tool Wear | Extends tool life by reducing heat and friction |

Need precision-machined PTFE components that meet your exact specifications?

At KINTEK, we specialize in machining PTFE for the semiconductor, medical, and laboratory industries. We understand that controlling heat is the key to achieving dimensional accuracy and a superior surface finish in every part.

We provide:

- Expert Thermal Management: Our advanced cooling techniques prevent warping and ensure tight tolerances.

- Custom Fabrication: From prototypes to high-volume orders, we deliver precision PTFE seals, liners, and labware.

- Material Expertise: We leverage sharp tooling and optimal machining parameters for flawless results.

Let us handle the complexities of PTFE machining for you. Contact KINTEK today for a quote and see how our precision production can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability