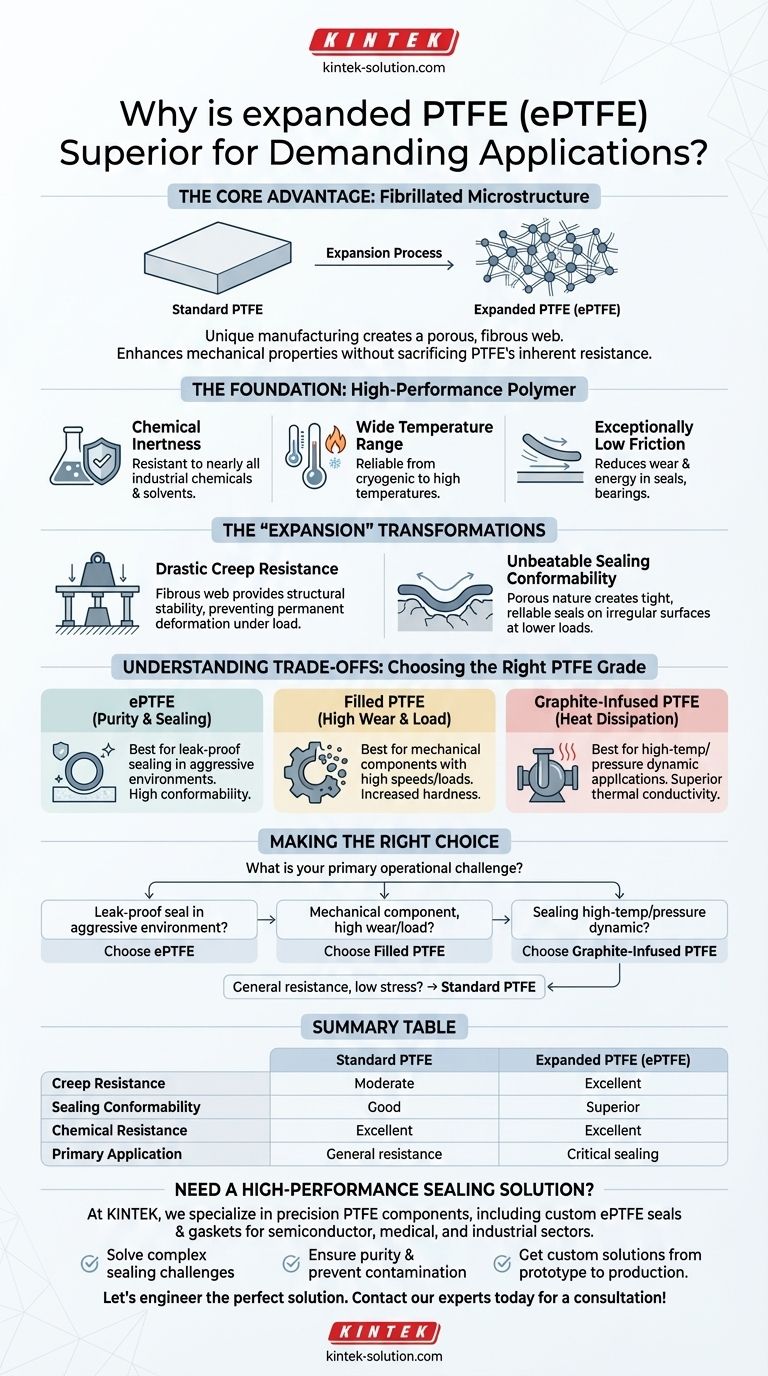

In short, expanded PTFE is superior for many demanding applications because its unique manufacturing process creates a porous, fibrous microstructure. This structure dramatically enhances the material's mechanical properties—like creep resistance and sealing ability—without sacrificing the exceptional chemical and thermal resistance inherent to standard PTFE.

The core reason for expanded PTFE's (ePTFE) superior performance lies in its fibrillated microstructure. This web-like internal structure provides excellent stability under pressure and allows it to conform perfectly to sealing surfaces, making it an exceptional gasket and sealing material, especially in chemically aggressive environments.

The Foundation: Why PTFE Is a High-Performance Polymer

To understand what makes ePTFE special, we must first recognize the powerful base material it comes from.

### Unmatched Chemical Inertness

Polytetrafluoroethylene (PTFE) is renowned for being resistant to nearly all industrial chemicals and solvents. This makes it a default choice for components in chemical processing, pharmaceuticals, and other corrosive environments.

### Wide Temperature Range

PTFE performs reliably across an extremely broad temperature spectrum. It remains functional in cryogenic conditions and at high temperatures where most elastomeric or plastic seals would fail.

### Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is invaluable for applications like seals, bearings, and bushings where reducing wear and operational energy is critical.

The "Expansion" Process: Transforming a Great Material into a Superior One

The key to ePTFE's enhanced capabilities is the physical transformation it undergoes. The expansion process creates a material that is both strong and conformable.

### Creating a Fibrillated Microstructure

During manufacturing, solid PTFE is stretched under specific conditions. This process, known as expansion or fibrillation, pulls the material apart, creating a web of interconnected fibers and nodes.

This resulting material is no longer a solid block but a porous, multidirectionally strong structure.

### Drastic Improvement in Creep Resistance

Standard PTFE can be prone to "creep" or cold flow, where the material deforms permanently under sustained pressure. The fibrous web of ePTFE provides immense structural stability, giving it excellent creep resistance and dimensional stability under load.

### Unbeatable Conformability for Sealing

The porous and soft nature of ePTFE allows it to conform to irregular or damaged flange surfaces, creating an extremely tight and reliable seal at lower bolt loads. This is a critical advantage for gaskets in industrial piping.

Understanding the Trade-offs: ePTFE vs. Other PTFE Grades

While ePTFE is superior for sealing, its "superiority" is context-dependent. Other modified PTFE grades are engineered for different demanding applications.

### When to Choose Filled PTFE: High Wear and Load

For applications like bushings or bearings that experience high speeds and heavy loads (high PV), filled PTFE is often the better choice. Adding fillers like glass, carbon, or bronze dramatically increases hardness and wear resistance, properties where unfilled ePTFE would be inadequate.

### When to Choose Graphite-Infused PTFE: Heat Dissipation

In high-temperature and high-pressure pumps or valves, heat buildup can be a major issue. Graphite-infused PTFE packing combines PTFE's chemical resistance with graphite's superior thermal conductivity, allowing it to dissipate heat far more effectively than ePTFE.

### When to Choose ePTFE: Purity and Sealing Integrity

In the chemical and pharmaceutical industries, purity and a perfect seal are paramount. The 100% pure PTFE composition and superior conformability of ePTFE gaskets make them the ideal choice to prevent leaks and contamination.

Making the Right Choice for Your Application

Selecting the correct PTFE variant requires a clear understanding of your primary operational challenge.

- If your primary focus is creating a leak-proof seal in a chemically aggressive environment: Choose expanded PTFE (ePTFE) for its unmatched conformability and creep resistance.

- If your primary focus is a mechanical component subject to high wear, speed, or pressure: Choose a filled PTFE grade (carbon, glass) for its superior hardness and durability.

- If your primary focus is sealing a high-temperature, high-pressure dynamic application like a pump shaft: Choose a graphite-infused PTFE packing for its enhanced thermal conductivity.

- If your primary focus is general chemical resistance without extreme mechanical stress: Standard, unfilled PTFE may provide the most cost-effective solution.

Ultimately, the right material is the one that is precisely engineered to solve your specific application's most demanding problem.

Summary Table:

| Key Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Creep Resistance | Moderate | Excellent |

| Sealing Conformability | Good | Superior |

| Chemical Resistance | Excellent | Excellent |

| Primary Application | General chemical resistance | Critical sealing in aggressive environments |

Need a high-performance sealing solution for a demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including high-performance expanded PTFE (ePTFE) seals and gaskets. Our expertise in custom fabrication ensures you get a component perfectly engineered for your specific needs—whether you're in the semiconductor, medical, laboratory, or industrial sector.

We can help you:

- Solve complex sealing challenges with ePTFE's superior conformability and creep resistance.

- Ensure purity and prevent contamination in critical processes.

- Get a custom solution, from prototypes to high-volume production.

Let's engineer the perfect solution for your most demanding problems. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications