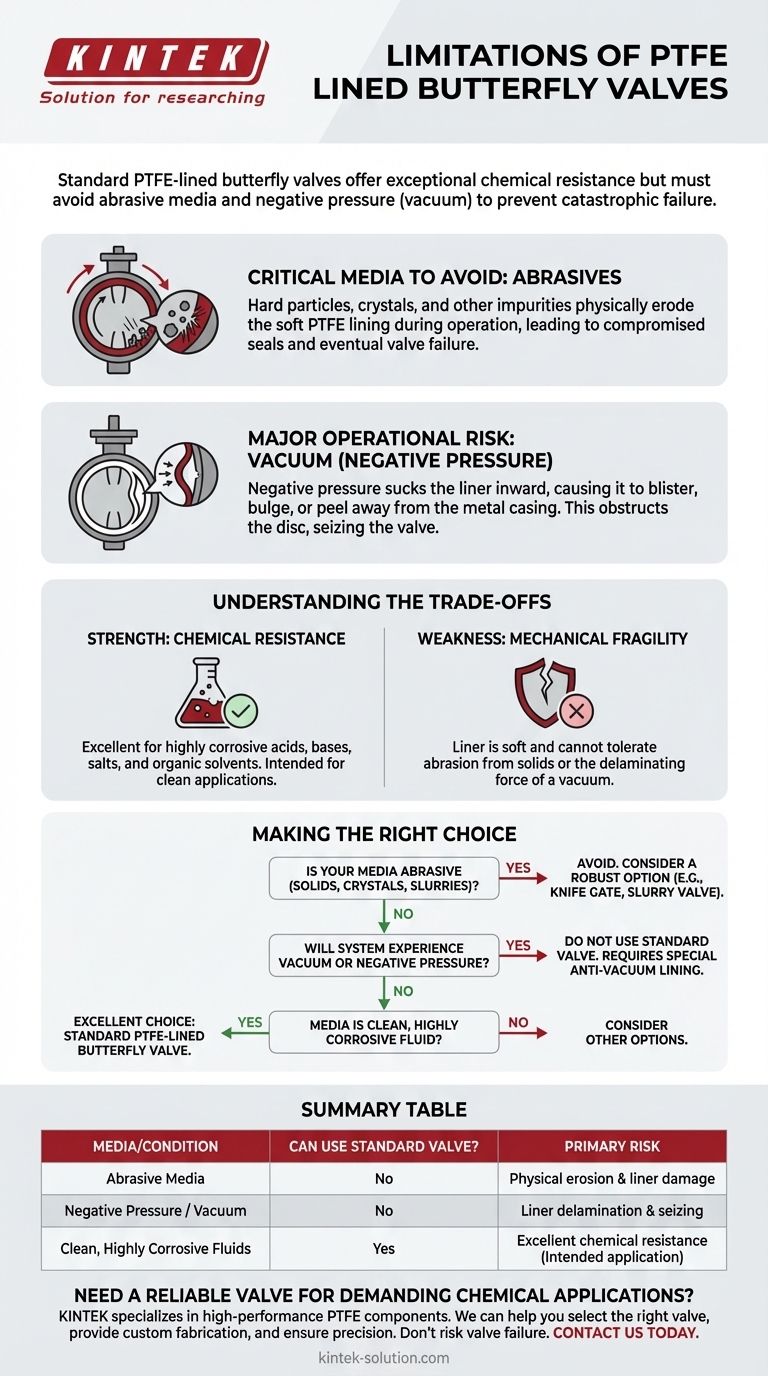

Critically, the primary media you must not use with a standard PTFE-lined butterfly valve are any fluids containing hard particles, crystals, or other abrasive impurities. These substances will physically damage the soft PTFE lining during operation, leading to compromised performance and eventual valve failure. Equally important, you must avoid any application where the pipeline can experience negative pressure (a vacuum).

The core limitation of a PTFE-lined valve is not its chemical resistance—which is outstanding—but its mechanical fragility. Success depends on protecting the soft liner from both abrasive media and the destructive force of pipeline vacuum conditions.

The Core Limitation: Abrasive Media

A PTFE lining provides a nearly inert chemical barrier, but it is a relatively soft material. Its primary vulnerability is to physical damage, specifically from abrasion.

Understanding Abrasive Wear

When a valve opens or closes, its disc rotates and wipes against the seat. If hard particles are present in the media, they become trapped between the disc and the soft PTFE liner.

This action effectively grinds the particles into the lining, causing scratches, gouges, and accelerated wear. This process physically erodes the protective layer.

Consequence of Abrasion

Even minor abrasive wear compromises the valve's seal. Over time, this leads to leakage, reduced flow control, and ultimately, complete valve failure. The protective benefit of the liner is lost once it has been physically breached.

The Critical Threat of Negative Pressure

Beyond the media itself, the most significant operational risk to a PTFE-lined valve is negative pressure. This condition is often overlooked but can cause catastrophic failure.

What is Negative Pressure (Vacuum)?

Negative pressure occurs when the pressure inside the pipeline drops below the atmospheric pressure outside. This creates a suction or vacuum effect within the system.

The "Delamination" Effect

The PTFE liner is bonded to the inner wall of the valve body. When a vacuum occurs, the external atmospheric pressure effectively pushes on the outside of the valve and "sucks" the liner inward, away from the valve body.

This can cause the liner to blister, bulge, or completely delaminate (peel away) from the metal casing.

Why This Leads to Failure

A delaminated or bulging liner will physically obstruct the valve's disc, preventing it from opening or closing properly. The valve becomes seized and non-functional, requiring a complete system shutdown and replacement.

Understanding the Trade-offs

Choosing a PTFE-lined valve involves balancing its exceptional chemical resistance against its specific physical vulnerabilities.

Strength: Unmatched Chemical Resistance

The primary reason to select a PTFE-lined valve is its ability to handle highly corrosive media. It is resistant to a vast range of acids, bases, salts, oxidants, and organic solvents where most metals would quickly fail.

Weakness: Mechanical Fragility

This chemical strength comes at the cost of mechanical softness. The liner cannot tolerate abrasion from solids or the delaminating force of a vacuum. It is designed exclusively for clean, non-abrasive liquid and gas service.

Other Considerations: Stress and Vibration

These valves can also be susceptible to damage from other forms of mechanical stress. Excessive vibration or system pressures that exceed the valve's design limits can damage the liner and seating components over time.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE-lined butterfly valve is appropriate for your specific operational environment.

- If your media contains solid particles, crystals, or is abrasive: Avoid this valve type entirely. Consider a more robust option like a knife gate valve or a specially designed slurry valve.

- If your system may experience vacuum conditions or negative pressure: Do not use a standard PTFE-lined valve. You must investigate valves with a specially designed anti-vacuum or anti-delamination lining.

- If your media is a clean, highly corrosive fluid (like strong acids or solvents): A PTFE-lined butterfly valve is an excellent choice, provided the system is free from abrasives and protected from vacuum.

Ultimately, matching the valve's specific limitations to your application's demands is the key to ensuring long-term system reliability.

Summary Table:

| Media/Operating Condition | Can a Standard PTFE-Lined Valve Be Used? | Primary Risk |

|---|---|---|

| Abrasive Media (solids, crystals, slurries) | No | Physical erosion and damage to the soft PTFE liner, leading to leaks and failure. |

| Negative Pressure / Vacuum | No | Liner delamination (blistering, bulging), causing the valve to seize. |

| Clean, Highly Corrosive Fluids (acids, solvents) | Yes | Excellent chemical resistance; this is the valve's intended application. |

Need a reliable valve for demanding chemical applications?

PTFE-lined butterfly valves are ideal for handling highly corrosive media, but their success depends on correct application. At KINTEK, we specialize in high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors.

We can help you:

- Select the right valve for your specific media and operating conditions.

- Provide custom fabrication from prototypes to high-volume orders to meet your exact specifications.

- Ensure precision and reliability with components designed to perform in critical environments.

Don't risk valve failure. Contact our experts today to discuss your application and ensure optimal performance and longevity for your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech