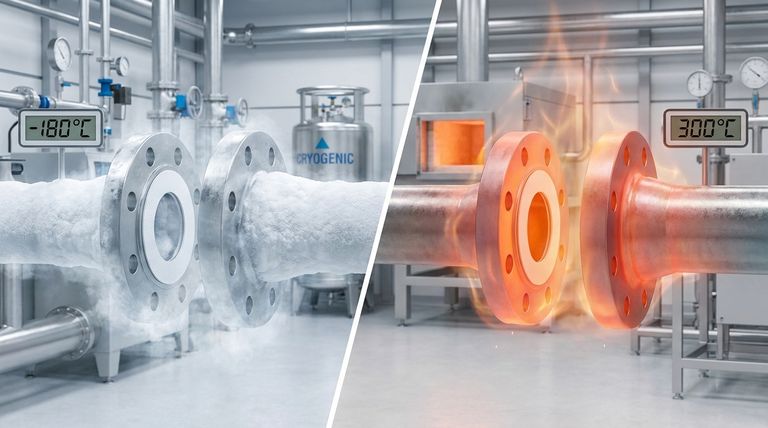

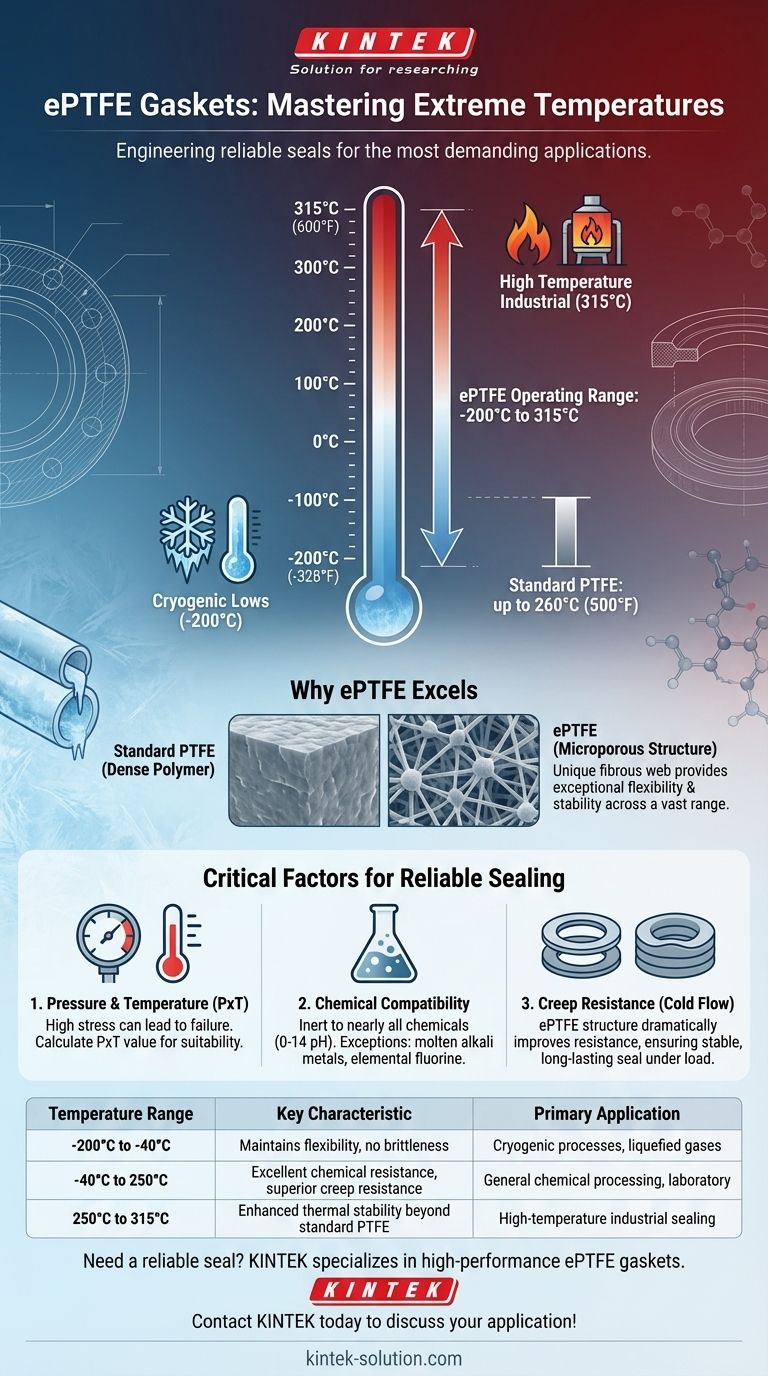

In short, ePTFE gaskets can operate in an extremely wide temperature range, typically cited from cryogenic lows of -200°C (-328°F) up to highs of 315°C (600°F). However, the precise service limit can vary based on the specific grade of the material and the operational pressures involved. This range significantly surpasses that of standard PTFE, which is generally rated up to 260°C (500°F).

The exceptional temperature range of ePTFE is a direct result of its unique microporous structure. However, to ensure a reliable seal, you must consider the interplay between temperature, pressure, and the specific chemical environment of your application.

Why ePTFE Excels in Extreme Temperatures

The superior performance of ePTFE (expanded polytetrafluoroethylene) stems from its manufacturing process, which transforms standard PTFE into a fundamentally different material.

The Unique Molecular Structure

Standard PTFE is a dense polymer. The "expansion" process creates a microporous structure of strong fibers interconnected by nodes.

This fibrous, web-like structure gives ePTFE gaskets unique properties, including exceptional flexibility and stability across a vast temperature range.

Performance in Cryogenic Conditions

Unlike many polymers that become extremely brittle and fail at low temperatures, ePTFE maintains its flexibility and sealing integrity even at cryogenic levels approaching -200°C (-328°F).

This makes it a premier choice for applications involving liquefied gases and other ultra-low temperature processes.

Stability at High Temperatures

The molecular stability of the fluorine-carbon bonds in PTFE provides the foundation for its heat resistance.

The expansion process enhances this, allowing high-grade ePTFE to maintain its mechanical strength and sealing capability up to 315°C (600°F), well beyond the limits of pure, non-expanded PTFE.

Understanding the Discrepancies in Reported Ranges

You will often see different temperature ratings for PTFE and ePTFE materials. This variance is not an error but reflects important differences in material grade and application context.

ePTFE vs. Standard PTFE

Standard PTFE gaskets are typically rated for service up to approximately 250°C to 260°C. The enhanced structure of ePTFE is what pushes the upper service limit to 315°C in premium grades.

Application-Specific Limitations

Some sources may cite a much lower temperature range, such as -40°C to 110°C. This usually refers to a specific product or application where other factors limit performance.

For example, a gasket with an adhesive backing will be limited by the temperature tolerance of the adhesive, not the ePTFE material itself.

Critical Factors Beyond Temperature

Temperature rating is only one part of the equation for a successful seal. A gasket's true performance limit is a function of temperature, pressure, and media combined.

The Impact of Pressure

High internal pressure exerts significant force on a gasket. When combined with high temperatures, this stress can lead to failure.

The PxT value (Pressure x Temperature) is a critical metric used by engineers to determine the suitability of a gasket material for a specific service, as it reflects the combined operational stress.

Chemical Compatibility

Both PTFE and ePTFE are famously inert, resistant to nearly all chemicals across the full 0-14 pH range.

The only common exceptions are molten alkali metals and elemental fluorine at high temperatures and pressures. Always confirm compatibility with your specific media.

Creep Resistance (Cold Flow)

One historical weakness of standard PTFE is its tendency to "creep" or cold-flow under bolt load, which can lead to a loss of sealing pressure over time.

The fibrous, multi-directional structure of ePTFE dramatically improves creep resistance, ensuring a more stable, long-lasting, and reliable seal, especially in thermal cycling applications.

Making the Right Choice for Your Goal

To select the correct material, you must evaluate your primary operational challenge.

- If your primary focus is cryogenic sealing: Choose ePTFE for its proven ability to remain flexible and effective at temperatures down to -200°C.

- If your primary focus is high-temperature industrial sealing: Select a premium grade of ePTFE rated for 315°C, but be sure to calculate the PxT value to ensure it can handle your service pressures.

- If your primary focus is general chemical service below 250°C: Standard PTFE may be a sufficient and more cost-effective choice, but ePTFE will provide a more reliable seal with better creep resistance.

Ultimately, understanding the properties of ePTFE allows you to engineer a safer and more durable seal for your most demanding applications.

Summary Table:

| Temperature Range | Key Characteristic | Primary Application |

|---|---|---|

| -200°C to -40°C | Maintains flexibility, no brittleness | Cryogenic processes, liquefied gases |

| -40°C to 250°C | Excellent chemical resistance, superior creep resistance | General chemical processing, laboratory |

| 250°C to 315°C | Enhanced thermal stability beyond standard PTFE | High-temperature industrial sealing |

Need a reliable seal for extreme temperatures? KINTEK specializes in manufacturing high-performance ePTFE gaskets and components for semiconductor, medical, laboratory, and industrial applications. Our precision-engineered PTFE solutions offer superior temperature resistance (-200°C to 315°C), excellent chemical compatibility, and enhanced creep resistance.

Whether you require standard components or custom fabrication from prototypes to high-volume orders, we deliver durable sealing solutions tailored to your specific operational challenges.

Contact KINTEK today to discuss your application requirements and get a quote for reliable ePTFE sealing solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

People Also Ask

- What factors affect the choice between Teflon and parchment for heat pressing? Achieve the Perfect Finish Every Time

- What are the key properties of Teflon (PTFE) used in custom parts? | Achieve Peak Performance

- How can Teflon packing be enhanced for specific applications? Tailor PTFE for Superior Performance

- Do PTFE gaskets require lubrication? Trust the Material for a Reliable Seal

- How do PTFE coated fasteners perform in marine and offshore environments? Superior Corrosion Protection for Critical Assets

- What are the key properties and applications of machined Teflon? Solve Extreme Engineering Challenges

- What is the significance of biocompatibility in PTFE fasteners for medical devices? Ensure Patient Safety and Device Reliability

- What industries commonly use PTFE bushings? Critical Applications in Chemical, Automotive, and Medical