To successfully mill Teflon (PTFE), you must adapt your strategy to its uniquely challenging properties. Success hinges on using exceptionally sharp cutting tools, managing thermal expansion, and implementing secure workholding to counteract the material's soft, slippery nature. These factors are far more critical than the sheer cutting force required.

The central challenge in milling Teflon isn't cutting the material, but controlling it. Success depends less on brute force and more on finessing the material's tendency to deform under pressure, expand with heat, and clog cutting tools.

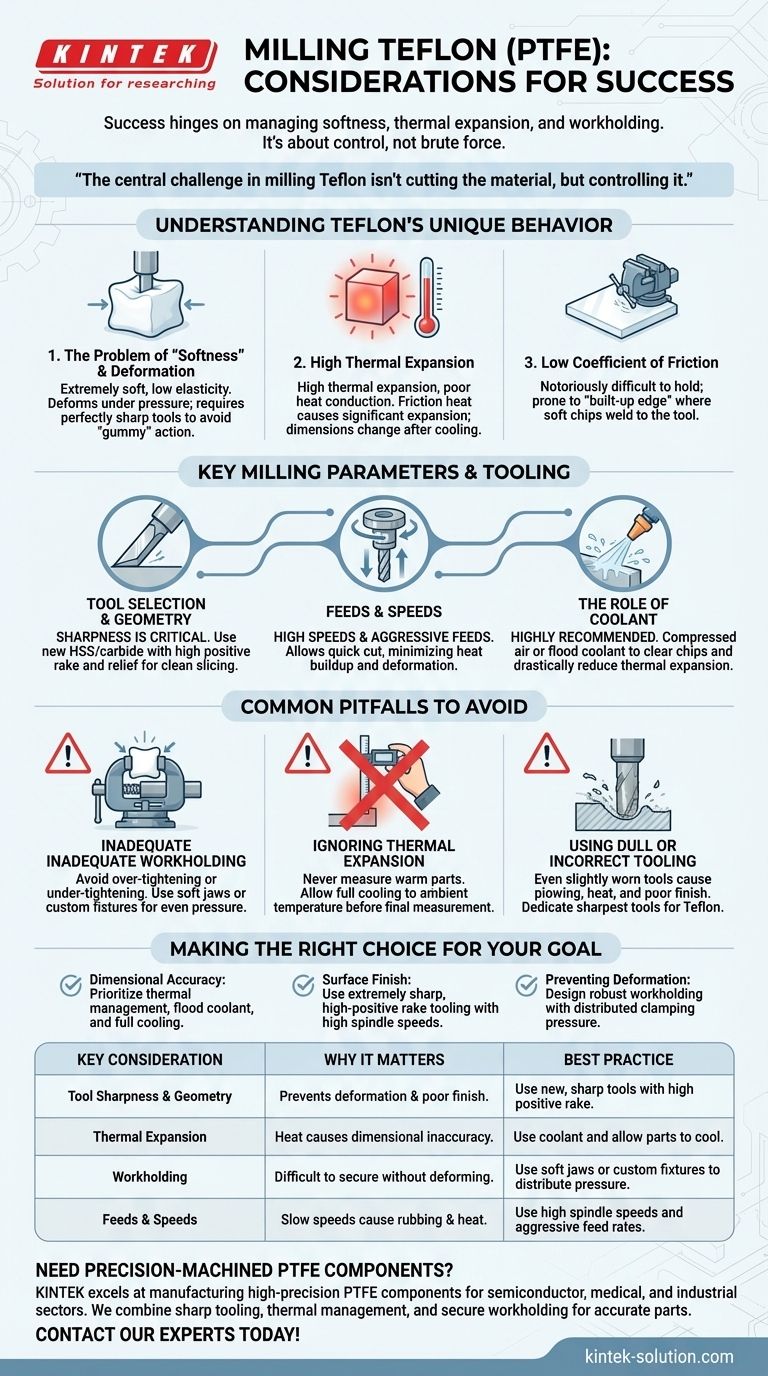

Understanding Teflon's Unique Machining Behavior

To machine Teflon effectively, you must first understand the root causes of its difficult behavior. The material's properties work against conventional machining intuition.

The Problem of "Softness" and Deformation

Teflon is an extremely soft material with a low modulus of elasticity. It has a tendency to push away or deform under tool pressure rather than shearing cleanly.

This deflection can lead to inaccurate dimensions and a "gummy" cutting action if the tool is not perfectly sharp.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion and does not conduct heat well. Friction from the cutting process creates localized heat that cannot easily dissipate.

This causes the material to expand significantly during milling. A part that is perfectly in-spec while warm may be out-of-spec once it cools to ambient temperature.

Low Coefficient of Friction

The characteristic slipperiness of Teflon presents two distinct problems. First, it makes the material notoriously difficult to hold securely in a vise or fixture.

Second, this property can cause soft, stringy chips to stick and weld themselves to the cutting tool, a phenomenon known as built-up edge, which ruins surface finish and accuracy.

Key Milling Parameters and Tooling

Adapting your tooling and machine parameters is essential to counteract Teflon's natural tendencies and produce a quality part.

Tool Selection and Geometry

Sharpness is the single most important factor. Use new or freshly sharpened cutters made from high-speed steel (HSS) or carbide.

Tools with a very high positive rake angle and significant relief are ideal. This geometry promotes a clean slicing action, which minimizes cutting forces and heat generation.

Feeds and Speeds

Generally, high cutting speeds and aggressive feed rates produce the best results. This strategy allows the tool to enter and exit the cut quickly, forming a chip before significant heat can build up and deform the workpiece.

Slow speeds can lead to rubbing instead of cutting, which generates excess heat and results in a poor surface finish.

The Role of Coolant

While Teflon can be machined dry, using a coolant is highly recommended. A steady stream of compressed air can clear chips effectively and provide some cooling.

For more intensive operations, a flood coolant is superior as it drastically reduces thermal expansion and helps prevent chips from sticking to the tool.

Common Pitfalls to Avoid

Many common machining practices will produce poor results with Teflon. Being aware of these pitfalls is critical for avoiding scrapped parts.

Inadequate Workholding

Do not simply clamp a piece of Teflon in a standard vise and expect good results. Over-tightening will crush the material and deform it, while under-tightening will allow it to shift or vibrate during the cut.

Use soft jaws or custom fixtures designed to distribute clamping pressure evenly without marring the part.

Ignoring Thermal Expansion

Never take a final measurement of a critical dimension immediately after a cut. The part will be warm and expanded, giving you a false reading.

Always allow the workpiece to cool and normalize to room temperature before performing final measurements or making finishing passes.

Using Dull or Incorrect Tooling

A tool that is even slightly worn will not shear Teflon cleanly. Instead, it will plow through the material, generating immense heat, causing heavy burring, and leaving a terrible surface finish.

Always dedicate your sharpest tools to Teflon, and do not use a tool that has previously cut metals without first resharpening it.

Making the Right Choice for Your Goal

Your specific approach should be tailored to the most critical outcome for your component.

- If your primary focus is dimensional accuracy: Prioritize thermal management by using flood coolant and allowing the part to fully cool before taking final measurements.

- If your primary focus is surface finish: Use extremely sharp, high-positive rake tooling with high spindle speeds to ensure a clean shearing action that minimizes burrs.

- If your primary focus is preventing part deformation: Design a robust workholding solution that secures the workpiece firmly without crushing or distorting it.

By respecting Teflon's unique properties instead of fighting them, you can achieve precise and repeatable results.

Summary Table:

| Key Consideration | Why It Matters | Best Practice |

|---|---|---|

| Tool Sharpness & Geometry | Prevents material deformation and poor surface finish. | Use new, sharp tools with a high positive rake angle. |

| Thermal Expansion | Heat from machining causes parts to expand, leading to dimensional inaccuracy. | Use coolant and allow parts to cool before final measurements. |

| Workholding | Teflon's slipperiness makes it difficult to secure without deforming. | Use soft jaws or custom fixtures to distribute pressure evenly. |

| Feeds & Speeds | Slow speeds cause rubbing and heat; fast speeds promote clean shearing. | Use high spindle speeds and aggressive feed rates. |

Need Precision-Machined PTFE Components?

Milling Teflon requires specialized expertise to overcome its unique challenges like softness and high thermal expansion. KINTEK excels at manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine sharp tooling, precise thermal management, and secure workholding to deliver dimensionally accurate parts with excellent surface finishes, from prototypes to high-volume orders.

Let us handle the complexities of PTFE machining for you. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications