At their core, the safety features of a PTFE lined butterfly valve stem directly from the exceptional properties of Polytetrafluoroethylene (PTFE) itself. These valves provide safety primarily through superior material integrity and reliable containment, preventing leaks of corrosive or hazardous substances, resisting failure under extreme temperatures, and ensuring consistent, clog-free operation.

The fundamental safety advantage of a PTFE lined butterfly valve is not a single added feature, but its inherent ability to resist chemical attack and thermal stress. This prevents the valve itself from becoming a point of failure in a critical system.

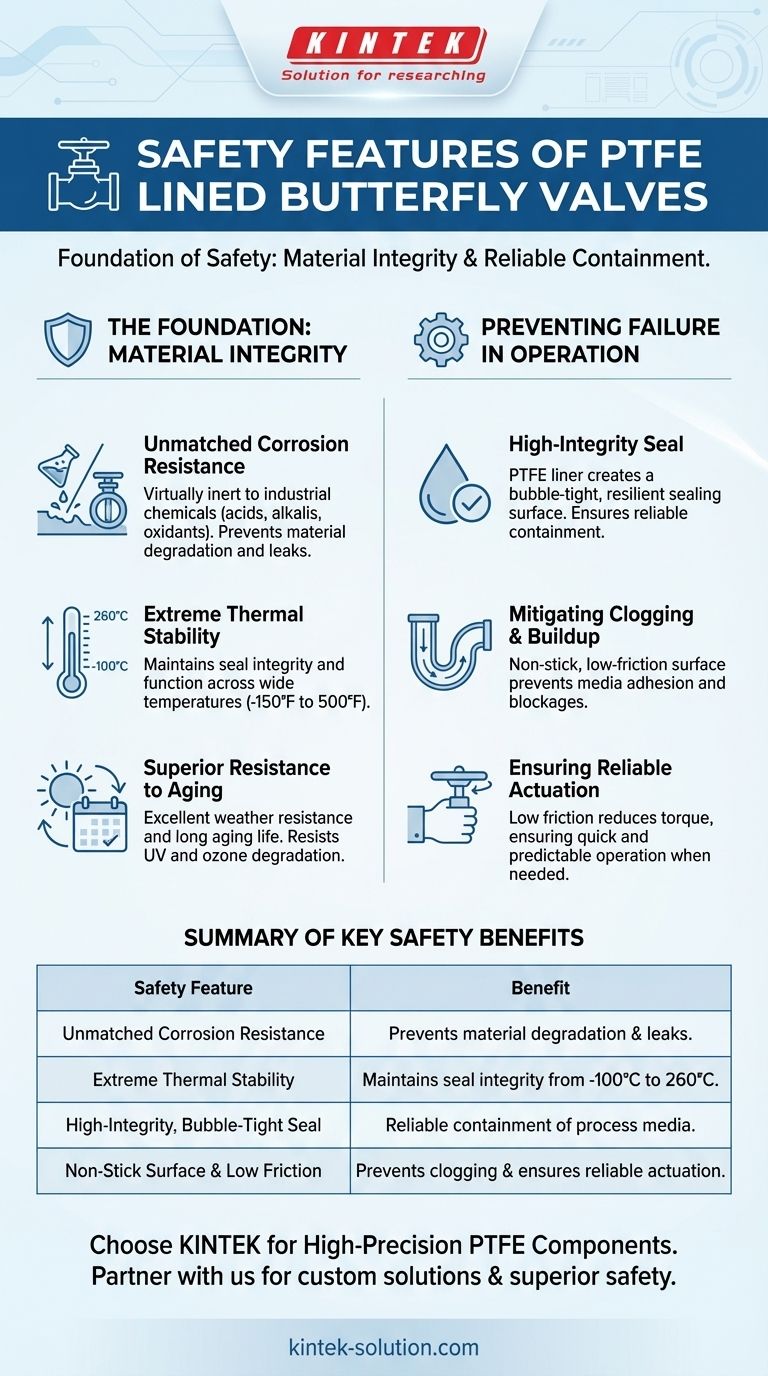

The Foundation of Safety: Material Integrity

The most critical aspect of valve safety is ensuring the valve's material can withstand the process media and operating conditions without degrading. PTFE provides a robust first line of defense.

Unmatched Corrosion Resistance

A primary cause of valve failure and hazardous leaks is corrosion. The valve body or internal components are eaten away by the process media, compromising the seal or structural integrity.

PTFE is virtually inert to almost all industrial chemicals, including strong acids, alkalis, and oxidants. This chemical resistance ensures the valve maintains its structure and sealing capability, directly preventing failures caused by material degradation.

Extreme Thermal Stability

Valves operating at temperature extremes are at risk of mechanical failure. Materials can become brittle when cold or lose their strength and shape when hot, leading to leaks.

PTFE maintains its properties across a wide temperature range, typically from -100°C up to 260°C (-150°F to 500°F). This stability ensures the valve provides a reliable seal and functions correctly even under significant thermal stress.

Superior Resistance to Aging

Materials can degrade over time due to environmental exposure. This can lead to unexpected failures in long-running systems.

PTFE has excellent weather resistance and a long aging life. It is not susceptible to degradation from UV light or ozone, ensuring long-term reliability and reducing the risk of a premature, age-related failure.

Preventing Failure in Operation

Beyond withstanding the environment, a valve must operate reliably and predictably to be considered safe. The PTFE liner enhances operational safety in several key ways.

Achieving a High-Integrity Seal

The most immediate safety function of any valve is to prevent leaks. The design and material of the seal are paramount.

The PTFE liner creates a tight, resilient sealing surface for the valve disc. This design is highly effective at providing a bubble-tight or near-zero-leakage shutoff, which is critical for containing hazardous or valuable media.

Mitigating Clogging and Buildup

Blockages in a pipeline can cause dangerous pressure spikes or halt production. The properties of the valve liner can either contribute to or prevent this problem.

PTFE is known for its non-stick properties, creating a very low-friction surface. This prevents media from sticking to and building up on the valve's internal components, ensuring smooth flow and mitigating the risk of clogging.

Ensuring Reliable Actuation

In many processes, especially emergencies, a valve must open or close quickly and predictably.

The low coefficient of friction of PTFE makes the valve easier to operate. It reduces the torque required to turn the disc, which in turn reduces wear and tear on the actuator and stem components, ensuring the valve will function when called upon.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not universally applicable. Understanding their limitations is key to safe system design.

Temperature Ceilings

Although the thermal range is wide, it is not infinite. Exceeding the maximum recommended temperature for PTFE can cause it to degrade, releasing hazardous fumes and compromising the valve's integrity.

Not for Abrasive Media

PTFE is a relatively soft material. It is not suitable for applications involving abrasive slurries or media with hard particulates, as these can quickly wear away the liner and destroy the seal.

Pressure Limitations

Butterfly valves, including lined versions, are generally intended for low-to-moderate pressure applications. Using them in systems that exceed their pressure rating can damage the liner and lead to catastrophic failure.

Making the Right Choice for Your Goal

Selecting the correct valve is a critical safety decision. The properties of a PTFE lined butterfly valve make it an ideal choice for specific, demanding applications.

- If your primary focus is handling highly corrosive chemicals: The chemical inertness of the PTFE liner is its greatest safety asset, preventing material degradation that leads to leaks.

- If your primary focus is process purity (e.g., pharmaceuticals, food): The non-stick, non-leaching properties of PTFE prevent media contamination and ensure consistent, predictable flow.

- If your primary focus is long-term, low-maintenance reliability: The durability and resistance to aging reduce the risk of unexpected failures and minimize personnel exposure for maintenance.

Ultimately, choosing a valve based on its fundamental material suitability is the foundation of a safe and reliable system design.

Summary Table:

| Safety Feature | Benefit |

|---|---|

| Unmatched Corrosion Resistance | Prevents material degradation and leaks from strong acids, alkalis, and oxidants. |

| Extreme Thermal Stability | Maintains seal integrity from -100°C to 260°C (-150°F to 500°F). |

| High-Integrity, Bubble-Tight Seal | Ensures reliable containment of hazardous or valuable process media. |

| Non-Stick Surface & Low Friction | Prevents media buildup and clogging; ensures reliable, low-torque actuation. |

Need a valve that guarantees safety and reliability?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated liners and seals for butterfly valves. Our expertise ensures your valves deliver the critical safety features you need—superior chemical resistance, thermal stability, and leak-free performance—for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production to create the perfect solution for your demanding application. Contact us today to discuss how our PTFE expertise can enhance the safety of your fluid handling systems.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE coating enhance corrosion resistance in fasteners? Achieve Unmatched Protection in Harsh Environments

- How do PTFE bearing pads contribute to structural safety and efficiency? Enhance Structural Integrity with Low-Friction Support

- What post-processing techniques are used for PTFE parts? Achieve Peak Performance & Reliability

- What cost advantages do PTFE lined butterfly valves offer? Achieve Superior Corrosion Resistance at Lower Costs

- What are the key characteristics of PTFE that make it suitable for lip seals? Engineered for Extreme Performance

- Which industries commonly use PTFE Expansion Bellows? Solve Your Critical Chemical and Purity Challenges

- What are the limitations of PTFE when used as a mechanical component? Overcoming Softness & Instability

- What are the disadvantages of using bronze as a filler in PTFE? Trade-offs in Chemical & Non-Stick Properties