At its core, Polytetrafluoroethylene (PTFE) is an ideal material for low-friction applications because it has one of the lowest coefficients of friction of any known solid. This inherent slipperiness allows it to function as a self-lubricating surface, drastically reducing the force needed to move parts against each other and minimizing wear and heat generation in mechanical systems.

While many materials require external lubricants like oil or grease to reduce friction, PTFE's unique molecular structure provides this property inherently. Understanding this distinction is the key to leveraging its power correctly, especially in applications where traditional lubrication is impossible or undesirable.

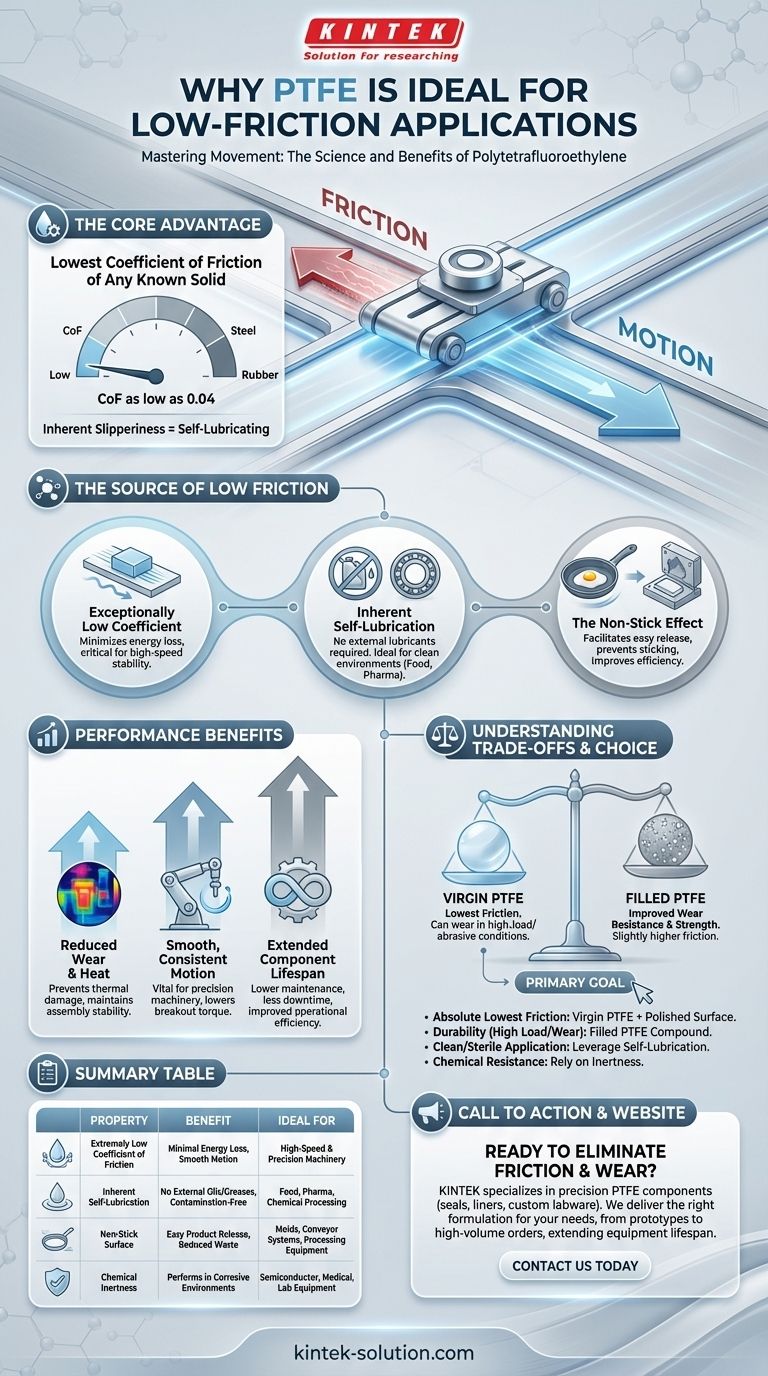

The Source of PTFE's Low Friction

PTFE's performance is not magic; it stems from a combination of its chemical structure and resulting physical properties. These factors make it a default choice for engineers solving for friction.

An Exceptionally Low Coefficient of Friction

PTFE boasts an extremely low coefficient of friction, with values for virgin-grade material recorded as low as 0.04. This means that very little energy is lost when two surfaces slide against it.

This property is fundamental to its use in high-speed or dynamic applications, where minimizing frictional heat is critical for operational stability and longevity.

Inherent Self-Lubrication

Because of its low friction, PTFE is considered self-lubricating. It does not require external oils or greases to maintain a slippery surface.

This is a decisive advantage in industries like food processing, pharmaceuticals, and textiles, where liquid lubricants could contaminate products or dissolve in process chemicals.

The "Non-Stick" Effect

The same property that reduces friction in mechanical parts is responsible for the famous "non-stick" quality of PTFE coatings on cookware.

In industrial settings, this facilitates the easy release of products from molds and prevents materials from sticking to conveyor systems or processing equipment, improving efficiency and reducing waste.

How Low Friction Translates to Performance

The theoretical benefit of low friction delivers tangible results in real-world machinery and components, improving efficiency, reliability, and cost-effectiveness.

Reduced Wear and Heat Generation

By minimizing resistance, PTFE significantly reduces the abrasive wear and tear on both itself and the mating surface.

Less friction also means less energy is converted into heat, preventing thermal damage and maintaining the stability of the entire assembly, especially in continuous-motion systems.

Smooth, Consistent Motion

Components like PTFE bearings, bushings, and guide rails ensure smooth and predictable movement. This consistency is vital for precision machinery and equipment.

It also lowers the "breakout torque" required to initiate movement in seals and other static applications, ensuring a responsive system.

Extended Component Lifespan

The direct result of reduced wear is a longer service life for the components. This leads to lower maintenance requirements, less downtime, and improved operational efficiency over the lifetime of the equipment.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its effectiveness depends on understanding its limitations and selecting the correct formulation for the job.

Friction vs. Wear Resistance

Virgin PTFE offers the absolute lowest coefficient of friction. However, it is a relatively soft material and can wear down in high-load or abrasive conditions.

Filled PTFE grades incorporate materials like glass, carbon, or bronze. These fillers dramatically improve wear resistance and mechanical strength but slightly increase the coefficient of friction.

Mechanical Strength and Pressure

Pure PTFE can deform under constant, heavy loads—a phenomenon known as "creep." Its performance is optimal under specific pressure and velocity (PV) limits.

For structural applications like bridge slide plates, PTFE is used as a sliding surface, but the load is borne by the underlying structure.

The Importance of Mating Surfaces

PTFE's low-friction properties are most effective when paired with a smooth, hard mating surface. A rough or abrasive counter-surface will accelerate wear and negate many of its benefits.

Making the Right Choice for Your Application

Selecting the correct approach depends entirely on your primary engineering goal.

- If your primary focus is the absolute lowest friction possible: Use virgin-grade PTFE and ensure a highly polished, smooth mating surface.

- If your primary focus is durability in a high-load or high-wear environment: Choose a filled PTFE compound, such as glass- or carbon-filled, accepting a minor trade-off in slipperiness for a major gain in longevity.

- If your primary focus is a clean or sterile application: Leverage PTFE's self-lubricating nature to design a system that requires no external oils or greases.

- If your primary focus is chemical resistance in a corrosive environment: Rely on PTFE's chemical inertness, which allows it to provide low friction where most other materials would degrade.

Properly applied, PTFE moves systems beyond simple lubrication toward truly frictionless design.

Summary Table:

| Key Property | Benefit | Ideal For |

|---|---|---|

| Extremely Low Coefficient of Friction (as low as 0.04) | Minimal energy loss, smooth motion, reduced heat generation | High-speed and precision machinery |

| Inherent Self-Lubrication | No need for external oils or greases, contamination-free | Food, pharmaceutical, and chemical processing |

| Non-Stick Surface | Easy product release, reduced waste, improved efficiency | Molds, conveyor systems, and processing equipment |

| Chemical Inertness | Performs in corrosive environments where other materials fail | Semiconductor, medical, and laboratory equipment |

Ready to eliminate friction and wear in your equipment?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right PTFE formulation (virgin or filled) for your specific needs, whether you require the absolute lowest friction or enhanced durability under high loads.

We offer custom fabrication from prototypes to high-volume orders, delivering components that extend equipment lifespan, reduce maintenance, and improve operational efficiency.

Contact us today to discuss how our PTFE solutions can solve your friction challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications