In short, Teflon is used to manufacture machine parts that must slide, seal, or insulate in harsh environments. Common examples include low-load gears, bearings, bushings, O-rings, seals, pipe linings, slide plates, and electrical housings where its unique properties are more critical than raw mechanical strength.

The core reason to choose Teflon (PTFE) for a machine part is not for strength, but for its unparalleled combination of low friction, chemical inertness, and stability across a vast range of temperatures. It solves problems that traditional metals and plastics cannot.

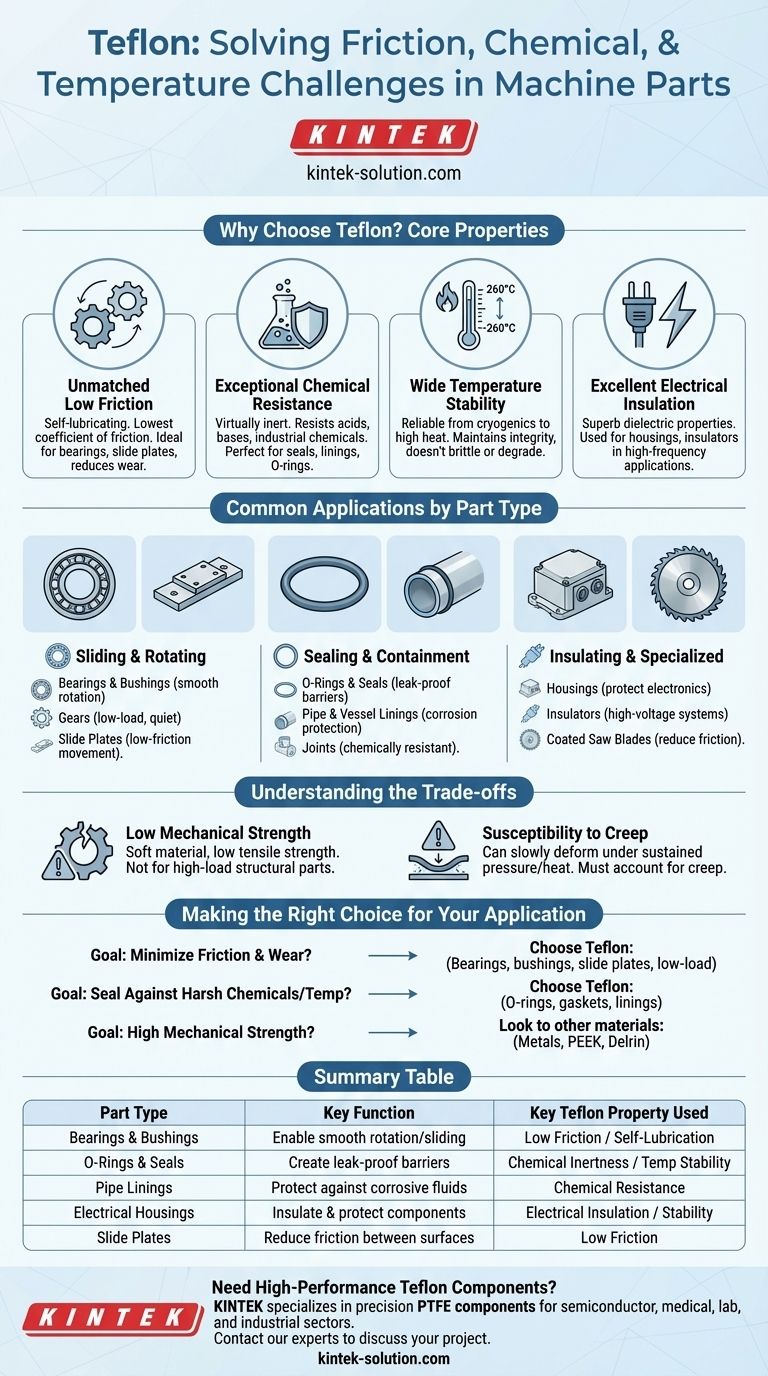

Why Choose Teflon? The Core Properties

Understanding the fundamental characteristics of Teflon explains its role in specialized mechanical applications. It excels where other materials fail due to friction, chemical attack, or extreme temperatures.

Unmatched Low Friction and Self-Lubrication

Teflon possesses one of the lowest coefficients of friction of any known solid material. This means parts move against each other with minimal resistance.

This self-lubricating property is critical for components like bearings and slide plates, as it reduces wear and tear, eliminates the need for external lubricants, and increases the machinery's operational lifespan.

Exceptional Chemical Resistance

Teflon is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This makes it an ideal material for seals, O-rings, and linings in pipes and vessels used in chemical processing, aerospace, and pharmaceutical industries where corrosive substances are common.

Wide Temperature Stability

Teflon performs reliably across an exceptionally broad temperature range, from cryogenic conditions (-260°C) up to high-heat applications (260°C).

This stability ensures that parts maintain their integrity and performance without becoming brittle in the cold or degrading in the heat, a crucial factor in many industrial and aerospace systems.

Excellent Electrical Insulation

As a superb electrical insulator, Teflon is frequently used for housings and connectors, especially in high-frequency applications.

Its resistance to high temperatures and moisture ensures stable electrical performance under demanding conditions.

Common Applications by Part Type

While the list of potential parts is long, they generally fall into three functional categories based on Teflon's key strengths.

Sliding and Rotating Components

Parts in this category leverage Teflon's extremely low friction.

- Bearings & Bushings: Allow shafts to rotate smoothly with minimal energy loss and wear.

- Gears: Used in low-load, low-speed applications where quiet operation and no lubrication are desired.

- Slide Plates: Provide a low-friction surface for heavy equipment or structural elements to move against each other.

Sealing and Containment

These applications rely on Teflon's chemical inertness and temperature resistance.

- O-Rings & Seals: Create a reliable barrier against leaks in aggressive chemical or high-temperature environments.

- Pipe & Vessel Linings: Protect the underlying structure of pipes and tanks from corrosive contents.

- Joints: Used as a sealing material in pipe joints to ensure a leak-proof and chemically resistant connection.

Insulating and Specialized Parts

This group takes advantage of Teflon's dielectric properties and overall stability.

- Housings: Protect sensitive electronic components from electrical interference and environmental factors.

- Insulators: Used in high-voltage and high-frequency electrical systems.

- Coated Saw Blades: While not a solid part, a Teflon coating reduces friction and resin buildup when cutting.

Understanding the Trade-offs

No material is perfect. Teflon's unique advantages come with significant limitations that must be respected in any design.

Low Mechanical Strength

Teflon is a relatively soft material. It has low tensile strength and is not suitable for high-load structural components that must bear significant force.

Attempting to use Teflon for a high-stress gear or a structural bracket would almost certainly lead to failure. Its strength is in its surface properties, not its bulk mechanical integrity.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, Teflon parts can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of seals and bearings to ensure long-term reliability.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary goal.

- If your primary focus is minimizing friction and wear: Teflon is an exceptional choice for bearings, bushings, and slide plates in low-to-moderate load systems.

- If your primary focus is sealing against harsh chemicals or extreme temperatures: Teflon is a leading material for O-rings, gaskets, and chemical-resistant linings.

- If your primary focus is high mechanical strength and load-bearing capacity: You must look to other materials like metals, PEEK, or Delrin, as Teflon is not suited for these tasks.

Ultimately, choosing Teflon is a strategic decision to solve specific challenges related to friction, chemicals, or temperature that other materials cannot handle.

Summary Table:

| Part Type | Key Function | Key Teflon Property Used |

|---|---|---|

| Bearings & Bushings | Enable smooth rotation/sliding | Low Friction / Self-Lubrication |

| O-Rings & Seals | Create leak-proof barriers | Chemical Inertness / Temperature Stability |

| Pipe Linings | Protect against corrosive fluids | Chemical Resistance |

| Electrical Housings | Insulate and protect components | Electrical Insulation / Stability |

| Slide Plates | Reduce friction between surfaces | Low Friction |

Need High-Performance Teflon Components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, bearings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the material advantages of Teflon with the exact specifications your application demands, from prototypes to high-volume production.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Do lubricating agents impact particle generation in PTFE? Yes, and here's how to control it.

- Are PTFE encapsulated O-rings compliant with industry standards? Ensure Purity & Performance in Critical Applications

- What are the structural differences between PTFE lined and hard seal butterfly valves? A Guide to Sealing Mechanisms

- What type of thermoplastic is Teflon and what are its inherent properties? | A Guide to PTFE's Unique Strengths

- What are the advantages of PTFE in chemically aggressive environments? Unmatched Chemical Resistance & Reliability

- What are the key properties of PTFE that make it suitable for sealing rings? Unmatched Chemical & Thermal Resistance

- What factors should be considered when selecting PTFE seals? Ensure Perfect Sealing for Your Critical Applications

- What are PTFE O-rings and their properties? A Guide to High-Performance Sealing