At its core, the significance of PTFE's extremely low coefficient of friction is its ability to create near-effortless movement between surfaces. This single property allows it to drastically reduce energy loss, minimize wear and tear, and often eliminate the need for traditional liquid lubricants in mechanical systems, leading to more efficient, durable, and lower-maintenance designs.

The fundamental value of PTFE isn't just that it's "slippery"; it's that this property enables the design of systems that run more efficiently, last longer, and operate more simply by engineering friction out of the equation from the start.

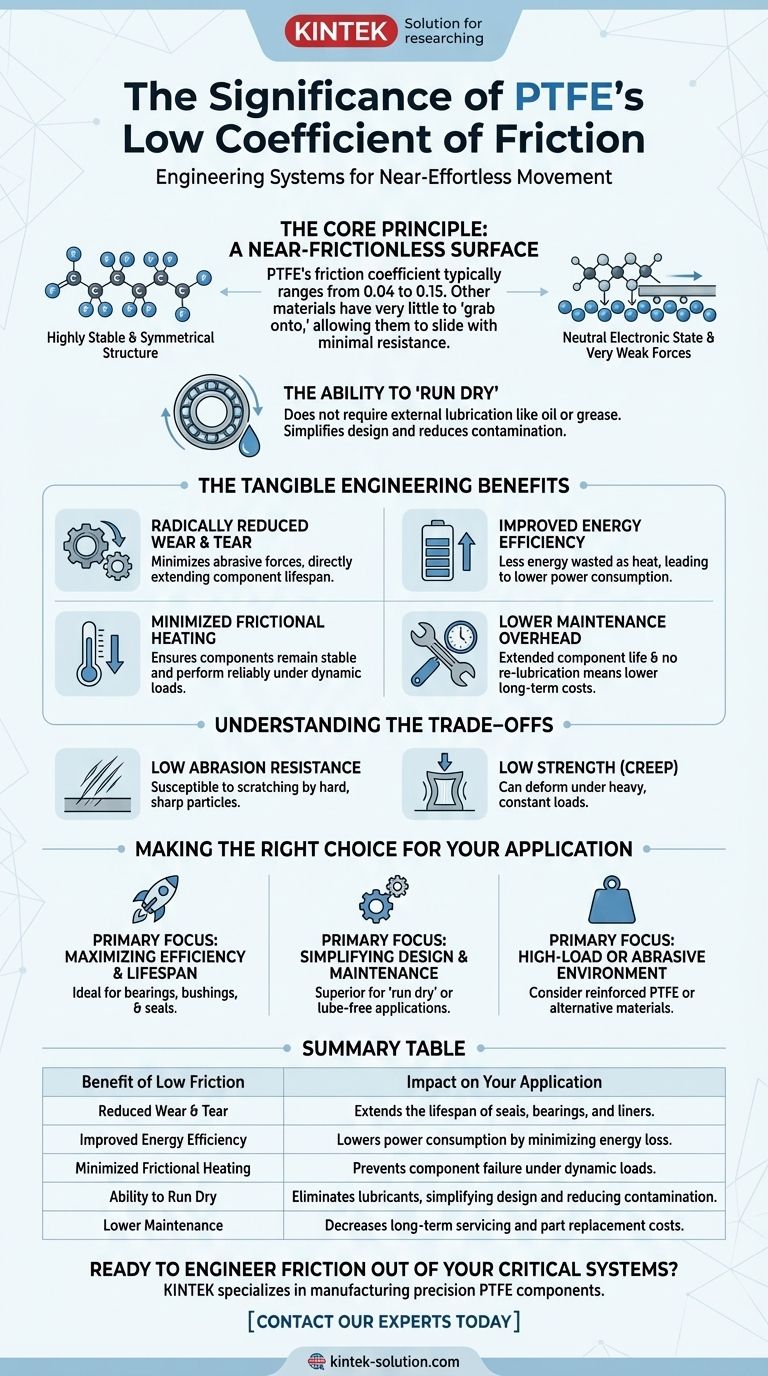

The Core Principle: A Near-Frictionless Surface

Polytetrafluoroethylene (PTFE) possesses one of the lowest coefficients of friction of any known solid material, typically ranging from 0.04 to 0.15. This characteristic is not a surface treatment but an inherent property of its molecular structure.

Why PTFE Is So Slippery

The fluorine atoms in PTFE's structure create a highly stable and symmetrical molecule. This symmetry causes the dipole moments to cancel out, resulting in a neutral electronic state with very weak forces of attraction to other surfaces.

In practical terms, this means other materials have very little to "grab onto," allowing them to slide across PTFE's surface with minimal resistance.

The Ability to 'Run Dry'

A critical consequence of this property is PTFE's ability to operate in "dry running" conditions. Unlike many materials, including elastomer seals, it does not require external lubrication like oil or grease to maintain low friction.

This simplifies mechanical design, reduces potential points of failure, and eliminates a common source of contamination and maintenance.

The Tangible Engineering Benefits

The abstract concept of low friction translates directly into significant, measurable advantages in real-world applications across industries like manufacturing, automotive, and aerospace.

Radically Reduced Wear and Tear

By minimizing the resistance between moving parts, PTFE dramatically reduces the abrasive forces that cause components to degrade over time. This directly extends the lifespan of components like bearings, seals, and gears.

Improved Energy Efficiency

Friction is a primary source of energy loss in any mechanical system. Reducing this friction means that less energy is wasted as heat, and more of the input power is converted into useful work.

This leads to lower energy consumption and more efficient machinery, a critical factor in everything from automotive engines to factory automation.

Minimized Frictional Heating

In high-speed or continuous-motion applications, the heat generated by friction can cause materials to warp, degrade, or fail. PTFE's low friction reduces potential frictional heating, ensuring components remain stable and perform reliably under dynamic loads.

Lower Maintenance Overhead

The combination of extended component life and the elimination of the need for lubrication results in lower long-term maintenance costs. Systems require less frequent servicing, part replacement, and manual intervention.

Understanding the Trade-offs

While its low friction is a tremendous asset, it's crucial to understand that the same molecular structure that creates this benefit also leads to certain limitations. This objectivity is key to proper material selection.

Low Strength and Abrasion Resistance

PTFE is a relatively soft material. While it excels at resisting sliding friction, it has low abrasion resistance and can be susceptible to scratching or gouging by hard, sharp particles.

Its low strength also means it can deform under heavy, constant loads—a phenomenon known as "creep" or "cold flow." For high-load structural applications, virgin PTFE is often unsuitable without reinforcement.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on its unique strengths and weaknesses. Consider your primary engineering goal to determine if it is the optimal choice.

- If your primary focus is maximizing efficiency and component lifespan: PTFE is an ideal material for bearings, bushings, and seals where reducing energy loss and wear from sliding contact is paramount.

- If your primary focus is simplifying design and reducing maintenance: PTFE's ability to run dry makes it a superior choice for applications where liquid lubricants are undesirable or impractical.

- If your primary focus is a high-load or abrasive environment: You should consider either a reinforced grade of PTFE (e.g., glass- or carbon-filled) or a different material entirely, as pure PTFE may lack the required mechanical strength.

Ultimately, leveraging PTFE's low friction is about designing systems that are inherently simpler, more durable, and more efficient.

Summary Table:

| Benefit of Low Friction | Impact on Your Application |

|---|---|

| Reduced Wear & Tear | Extends the lifespan of seals, bearings, and liners. |

| Improved Energy Efficiency | Lowers power consumption by minimizing energy loss. |

| Minimized Frictional Heating | Prevents component failure under dynamic loads. |

| Ability to Run Dry | Eliminates lubricants, simplifying design and reducing contamination. |

| Lower Maintenance | Decreases long-term servicing and part replacement costs. |

Ready to engineer friction out of your critical systems?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that leverage this low-friction advantage for superior performance. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance the efficiency, durability, and reliability of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fillers are used to enhance PTFE properties? Tailor PTFE for Superior Wear and Strength

- What are the features of modified PTFE? Achieve Superior Sealing and Structural Performance

- How is PTFE fine powder resin produced? The Key Role of Dispersion Polymerization

- What is PTFE and what is it commonly known as? The Ultimate Guide to Teflon & Its Uses

- How does Teflon compare to rubber in terms of performance? A Guide to Selecting the Right Material for Extreme Conditions

- How was PTFE discovered and what were its initial findings? A Serendipitous Breakthrough in Material Science

- What are the main components of PTFE's chemical structure? The Power of Carbon and Fluorine

- What is the best type of bearings for off-road use? The Definitive Guide to Rubber Sealed (2RS) Bearings