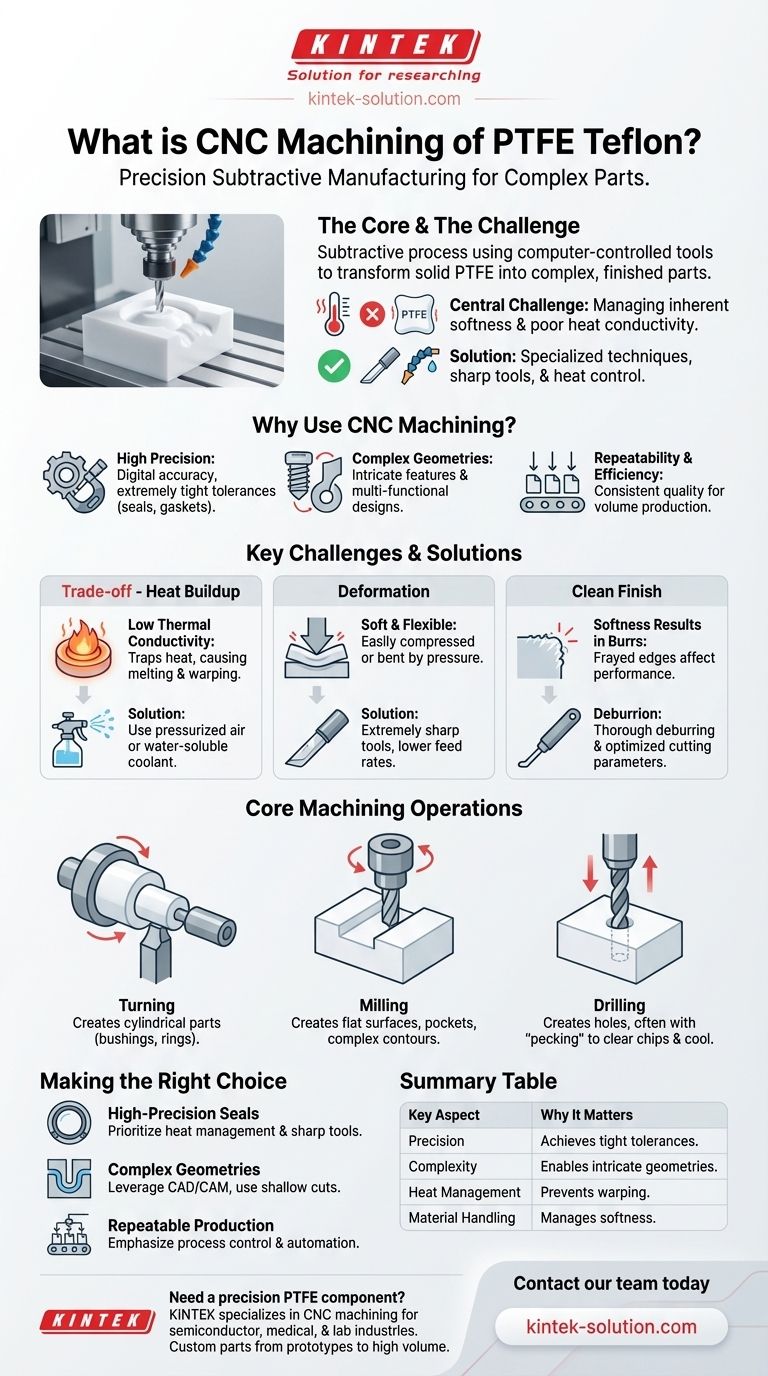

At its core, CNC machining of PTFE (Teflon) is a subtractive manufacturing process that uses computer-controlled cutting tools to precisely remove material from a solid block of PTFE. This method transforms raw stock into finished parts with complex geometries and tight tolerances that are often impossible to achieve with traditional molding or fabrication techniques.

The central challenge of machining PTFE is not the cutting itself, but managing the material's inherent softness and poor heat conductivity. Success depends entirely on specialized techniques—like using exceptionally sharp tools and controlling heat buildup—to achieve precision without deforming the part.

Why Use CNC Machining for PTFE?

While PTFE can be formed in other ways, CNC machining offers distinct advantages, particularly when precision and complexity are required. It unlocks the material's full potential for demanding applications.

The Pursuit of High Precision

CNC systems provide digital accuracy, allowing for the creation of parts with extremely tight tolerances.

This level of control is critical for components like seals, gaskets, and bearings, where even minor dimensional inaccuracies can lead to failure. The process ensures parts are made exactly to specification, without the warping that can occur in high-temperature molding.

Enabling Complex Geometries

CNC machining excels at producing intricate features like threads, grooves, and complex curves.

This capability is essential for modern engineering designs that require multi-functional parts. The computer-guided tool can follow complex paths that would be impractical for manual processes.

Ensuring Repeatability and Efficiency

Once a toolpath is programmed, a CNC machine can produce thousands of identical parts with minimal deviation.

This high repeatability is crucial for volume production, ensuring consistent quality across the entire run. The automation inherent in the process also reduces human error and optimizes production time, making it highly efficient.

Understanding the Trade-offs: Key Challenges of PTFE

Machining PTFE is fundamentally different from machining metals or even other plastics. Its unique properties present specific challenges that must be addressed with careful technique.

Managing Heat Buildup

PTFE has very low thermal conductivity, meaning it does not dissipate heat well. The friction from cutting tools can quickly generate heat that gets trapped in the material.

This localized heat can cause the PTFE to melt, gum up on the tool, or expand and warp, destroying the part's dimensional accuracy. The solution involves using pressurized air or a water-soluble coolant to actively remove heat from the cutting zone.

Preventing Material Deformation

As a very soft and flexible material, PTFE can easily be compressed or bent by tool pressure or improper clamping.

To prevent this, machinists use extremely sharp cutting tools to shear the material cleanly rather than pushing it. Lower feed rates and shallow depths of cut are also employed to minimize the cutting force exerted on the workpiece.

Achieving a Clean Finish

The softness of PTFE can result in burrs or frayed edges after a cut. These imperfections can affect the performance of seals or the fit of assembled parts.

A crucial final step is thorough deburring to remove any sharp or raised edges. The right combination of tool sharpness, cutting speed, and feed rate is the primary strategy for minimizing burrs from the start.

The Core Machining Operations

While many operations are possible, three core processes form the foundation of most PTFE machining projects.

Turning

Turning is used to create cylindrical parts by rotating the PTFE workpiece while a stationary cutting tool removes material. This is ideal for producing components like bushings, rings, and nozzles.

Milling

Milling involves a rotating cutting tool removing material from a stationary workpiece. This process is used to create flat surfaces, pockets, slots, and complex 3D contours.

Drilling

Drilling creates holes in the PTFE workpiece. Due to heat buildup, specialized drills designed for plastics are often used, and the process may involve "pecking"—drilling a short distance and retracting to clear chips and allow cooling.

Making the Right Choice for Your Application

Selecting the right approach to machining PTFE depends entirely on your project's specific goals.

- If your primary focus is high-precision seals or bearings: Prioritize techniques that manage heat and prevent deformation, such as using sharp, specialized tools and effective coolants.

- If your primary focus is complex geometries for fluidic devices: Leverage the design freedom of CAD/CAM, but ensure your toolpaths account for PTFE's softness by using lower feed rates and shallow cuts.

- If your primary focus is repeatable, cost-effective production: Emphasize process control and automation to maintain consistent quality and minimize waste, but factor in that cycle times may be longer than for harder materials.

Ultimately, successfully machining PTFE is less about raw power and more about a finessed approach that respects the unique properties of the material.

Summary Table:

| Key Aspect | Why It Matters for PTFE Machining |

|---|---|

| Precision | Achieves tight tolerances critical for seals, bearings, and labware. |

| Complexity | Enables intricate geometries like threads, grooves, and fluidic paths. |

| Heat Management | Prevents warping and deformation with specialized coolants and techniques. |

| Material Handling | Uses sharp tools and controlled feeds to manage PTFE's softness. |

Need a precision PTFE component? KINTEK specializes in CNC machining PTFE Teflon for the semiconductor, medical, and laboratory industries. We combine expert material knowledge with advanced manufacturing to deliver custom parts—from prototypes to high-volume orders—that meet your exact specifications. Contact our team today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does the lifespan of PTFE lined pipes compare to standard steel pipes? Maximize Longevity in Corrosive Environments

- How are Teflon sheets used in hardware manufacturing? Solve Extreme Friction, Chemical, and Heat Problems

- What makes Teflon valuable for electrical applications? Leverage its High-Performance Insulating Properties

- Does modified PTFE (mPTFE) always outperform regular PTFE in seal performance? Make the Right Material Choice

- What are some everyday uses of Teflon sheets? From Cookware to Cars, Discover Its Hidden Role

- What advantages do PTFE O-rings offer? Superior Sealing for Extreme Chemical & Thermal Environments

- What are the physical and chemical properties of pure PTFE bushings? Unlock Extreme Chemical & Thermal Resistance

- What are the optimal load and speed conditions for PTFE performance? Master the PV Limit for Longevity