At its core, PTFE stands for Polytetrafluoroethylene. It is a high-performance synthetic fluoropolymer, a type of plastic most famously known by the brand name Teflon. This material is not a single-use plastic but a highly engineered polymer valued for its unique and powerful properties.

The true value of PTFE lies in its chemistry. The exceptionally strong bond between carbon and fluorine atoms gives the material a unique combination of properties—low friction, chemical inertness, and high-temperature resistance—making it a critical problem-solver in countless industries.

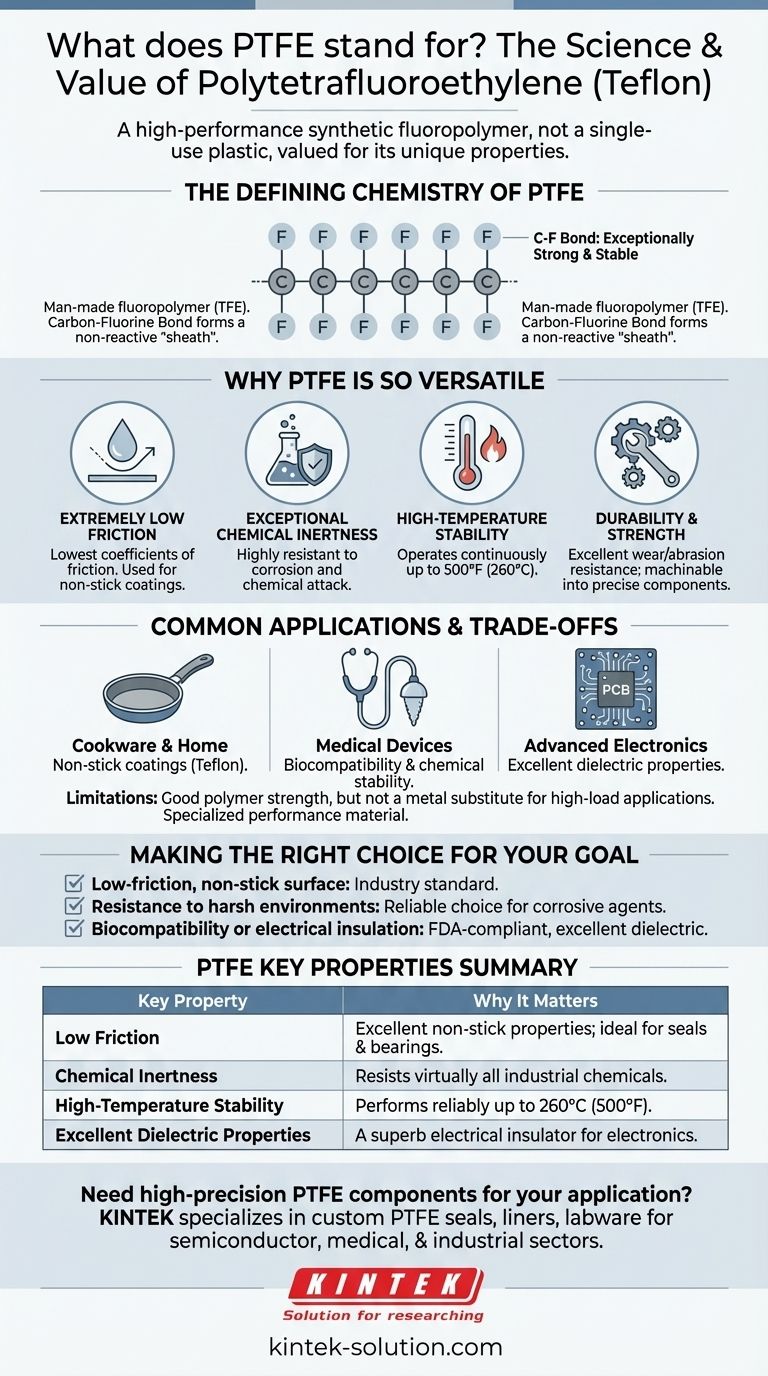

The Defining Chemistry of PTFE

To understand why PTFE is so useful, we must first look at its molecular structure. Its properties are not accidental; they are a direct result of its chemical makeup.

A Synthetic Fluoropolymer

PTFE is a man-made polymer, meaning it consists of long, repeating chains of a single molecule. In this case, that molecule is tetrafluoroethylene, or TFE.

The Power of the Carbon-Fluorine Bond

The defining feature of PTFE is the bond between carbon and fluorine atoms. This bond is one of the strongest in organic chemistry.

This exceptional strength means the fluorine atoms create a stable, non-reactive "sheath" around the carbon backbone of the polymer chain.

Why PTFE Is So Versatile

This unique chemical structure translates directly into a set of valuable real-world properties. These characteristics make PTFE an incredibly versatile material choice.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is why it is used for non-stick coatings on pans; very few things will adhere to its surface.

Exceptional Chemical Inertness

The strong carbon-fluorine bonds make the material highly resistant to corrosion and chemical attack. It is inert to most industrial chemicals, which makes it ideal for use in harsh environments.

High-Temperature Stability

PTFE can operate continuously at high temperatures, often up to 500°F (260°C), without degrading. This thermal stability expands its use into demanding applications.

Durability and Strength

In addition to its other properties, PTFE exhibits excellent wear and abrasion resistance and good mechanical strength for a polymer. It is also a material that is relatively easy to machine into precise components.

Common Applications and Trade-offs

The unique combination of properties makes PTFE a material of choice in fields that seem completely unrelated, from home cookware to advanced electronics.

From Cookware to Medical Devices

The most recognized application is Teflon non-stick coatings. However, its low friction and chemical stability also make it critical for medical devices, while its electrical properties are valuable for high-frequency circuit boards (PCBs).

Understanding the Limitations

While highly capable, PTFE is not a universal solution. Its mechanical strength, while good for a polymer, is not a substitute for metals in high-load structural applications. Furthermore, as a specialized performance material, it can be more costly than common commodity plastics.

Making the Right Choice for Your Goal

PTFE is a highly specialized material designed to solve specific challenges. Understanding its core strengths helps determine where it will provide the most value.

- If your primary focus is a low-friction, non-stick surface: PTFE is the industry standard for creating surfaces that resist adhesion.

- If your primary focus is resistance to harsh environments: Its chemical inertness and high-temperature stability make it a reliable choice for components exposed to corrosive agents.

- If your primary focus is biocompatibility or electrical insulation: PTFE is FDA-compliant and possesses excellent dielectric properties, making it suitable for medical and high-frequency electronics.

Ultimately, PTFE is a premier example of how molecular engineering creates materials that solve difficult technical problems.

Summary Table:

| Key Property | Why It Matters |

|---|---|

| Low Friction | Excellent non-stick properties; ideal for seals and bearings. |

| Chemical Inertness | Resists virtually all industrial chemicals; perfect for corrosive environments. |

| High-Temperature Stability | Performs reliably up to 260°C (500°F). |

| Excellent Dielectric Properties | A superb electrical insulator for electronics. |

Need high-precision PTFE components for your application? KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the material performance and precision your project demands. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its key properties? Unlock the Power of Teflon™

- How does PTFE resist chemical attacks? The Science Behind Its Unmatched Chemical Inertness

- Why is it difficult to glue materials to Teflon (PTFE)? Understand the Science & Solutions

- What mechanical and electrical properties make PTFE suitable for diverse applications? Unlock Versatility and Reliability

- What industries commonly use RPTFE and for what purposes? Enhance Durability in High-Load Applications

- What are some alternative materials to Teflon and their properties? Find the Right High-Performance Polymer for Your Application

- What is the volume resistivity and power factor of PTFE? Discover the Ultimate Electrical Insulator

- How does Teflon compare to rubber in terms of performance? A Guide to Selecting the Right Material for Extreme Conditions