At their core, PTFE lined butterfly valves offer significant cost advantages by allowing you to use a standard, less expensive valve body while achieving the high-level corrosion resistance of rare-metal alloys. This strategy dramatically lowers initial acquisition costs and reduces long-term maintenance expenses, providing superior cost performance, especially when handling aggressive media.

The central value proposition is simple: a PTFE liner delivers the performance of an exotic alloy at a fraction of the price. This shifts the financial calculation from high upfront costs to a more favorable total cost of ownership through reduced maintenance and extended service life.

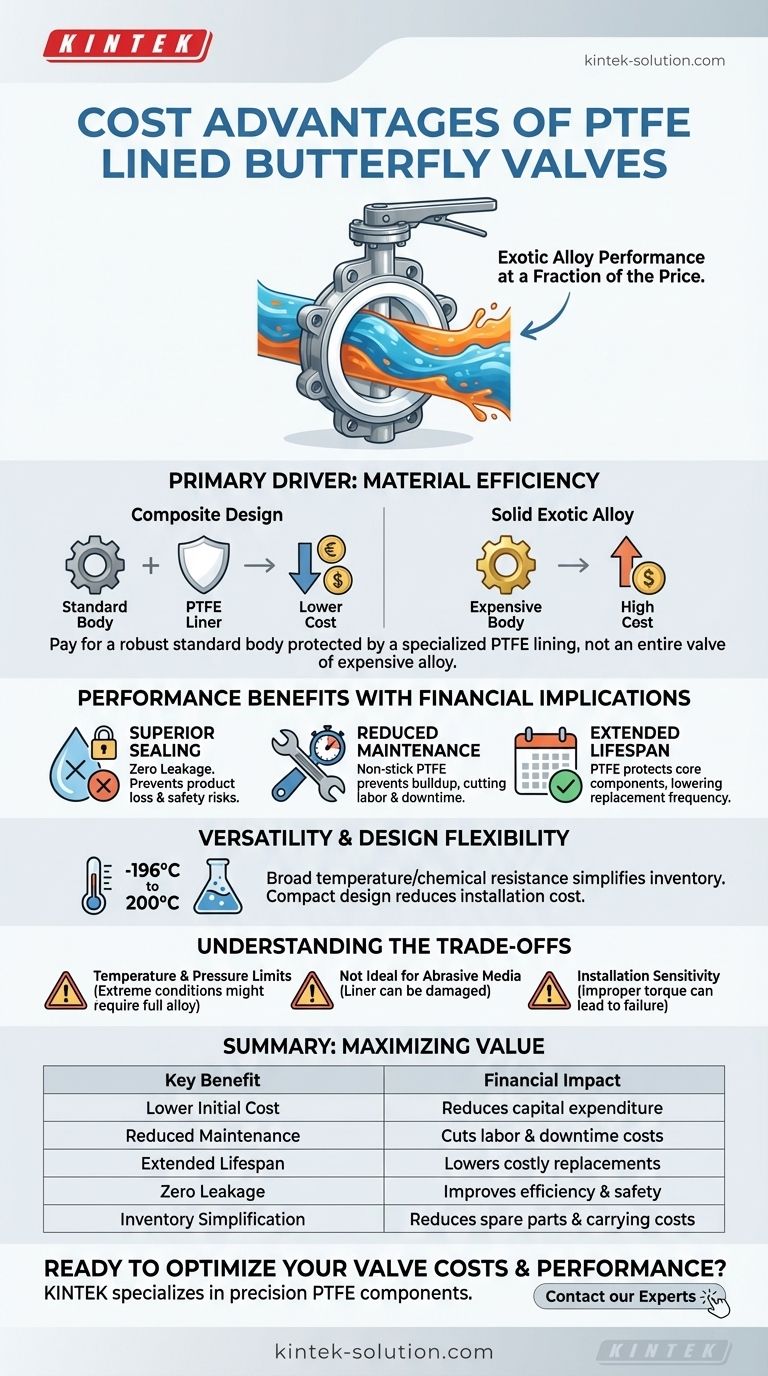

The Primary Driver of Cost Savings: Material Efficiency

The most significant financial benefit stems from the valve's composite design. You are not paying for a valve body made entirely of an expensive, corrosion-resistant material. Instead, you are paying for a robust but standard body protected by a highly effective, specialized lining.

Avoiding Expensive Alloys

The PTFE liner is the component that comes into contact with the corrosive media. This means the main valve body can be manufactured from more common and cost-effective materials.

This design completely eliminates the need to specify valves constructed from expensive and rare alloys to handle strong acids, alkalis, or oxidizers.

Reducing Maintenance and Downtime

The non-stick properties of PTFE are a key operational advantage. Its low coefficient of friction prevents media buildup and scaling on the valve's internal surfaces.

This feature ensures a smoother flow and significantly reduces the need for frequent cleaning and maintenance cycles, directly cutting labor costs and minimizing process downtime.

Extending Component Lifespan

By acting as a durable shield, the PTFE lining protects the core valve components—like the disc and body—from chemical attack and wear.

This protection extends the operational lifespan of the entire valve assembly, reducing the frequency of costly replacements and improving the return on your initial investment.

Performance Benefits with Financial Implications

Beyond direct material savings, the performance characteristics of these valves translate into further, indirect cost advantages that impact overall system efficiency.

Superior Sealing and Process Integrity

PTFE lined valves are known for their excellent sealing capabilities, often achieving zero leakage.

Preventing leaks is a direct cost saving. It means no lost product, reduced environmental and safety risks, and more efficient energy use within the system.

Versatility Simplifies Inventory

These valves possess excellent resistance to a wide range of chemicals and temperatures, with a typical operating range from -196°C to 200°C.

This versatility allows a single valve specification to be used across multiple applications in a plant, which can simplify procurement, reduce spare parts inventory, and lower associated carrying costs.

Installation and Design Flexibility

PTFE lined butterfly valves are typically lightweight and have a compact, space-saving design compared to other valve types.

This can lead to lower installation costs, as they require less structural support and are easier to handle. Their flexibility in installation position also allows for more efficient and cost-effective piping system designs.

Understanding the Trade-offs

While highly cost-effective, these valves are not a universal solution. Understanding their limitations is critical for making a sound financial decision.

Temperature and Pressure Boundaries

Although the temperature range is broad, PTFE can be compromised under certain high-temperature and high-pressure combinations. In extreme service conditions, a full-body alloy valve may still be the only viable, albeit more expensive, option.

Not Ideal for Abrasive Media

PTFE is a relatively soft material. It provides world-class chemical resistance but can be quickly damaged by media containing abrasive particles or slurries. Using it in such an application can lead to premature liner failure, negating any initial cost savings.

Installation Sensitivity

The integrity of the liner is paramount. Improper installation, such as over-tightening flange bolts, can damage the PTFE lining at the sealing faces. This can create a leak path and lead to rapid failure of the valve.

Making the Right Choice for Your Application

To determine if a PTFE lined butterfly valve is the most cost-effective solution, align your decision with your primary operational goal.

- If your primary focus is minimizing upfront capital expenditure: These valves are an exceptional choice for corrosive service, delivering the required chemical resistance without the high cost of exotic alloys.

- If your primary focus is reducing long-term operational costs: The combination of low maintenance requirements, extended lifespan, and zero-leakage performance makes them a powerful tool for lowering the total cost of ownership.

- If your primary focus is process versatility and standardization: Their wide chemical and temperature compatibility allows you to simplify inventory and use one valve type for many different corrosive applications.

Ultimately, choosing a PTFE lined butterfly valve is a strategic decision that balances upfront investment with long-term reliability and operational efficiency.

Summary Table:

| Cost Advantage | Key Benefit | Financial Impact |

|---|---|---|

| Lower Initial Cost | Standard valve body with PTFE liner vs. full exotic alloy | Reduces upfront capital expenditure |

| Reduced Maintenance | Non-stick PTFE prevents buildup, minimizes cleaning | Cuts labor costs and process downtime |

| Extended Lifespan | Liner protects core components from chemical attack | Lowers frequency of costly replacements |

| Zero Leakage | Superior sealing prevents product loss and risks | Improves process efficiency and safety |

| Inventory Simplification | Versatile for many corrosive applications | Reduces spare parts and carrying costs |

Ready to optimize your valve costs and performance?

KINTEK specializes in precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication—from prototypes to high-volume orders—ensures you get the exact PTFE lined butterfly valve solution to maximize your cost savings and operational efficiency.

Contact our experts today to discuss your specific application and receive a tailored solution that delivers superior value.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the two primary types of PTFE used in slide bearings and their respective applications? Choose the Right Grade for Your Load and Environment

- What affects the thickness tolerance of PTFE gasket sheets? The Critical Role of Manufacturing Process

- Why are PTFE expansion bellows advantageous in hygienic industries? Ensure Product Purity and System Integrity

- In what applications are PTFE reducing flanges versatile? Solve Critical Connections in Demanding Industries

- What are the key properties of ePTFE? Unlock Superior Sealing, Filtration & Medical Solutions

- What are the properties of stainless steel-reinforced PTFE? A High-Performance Composite for Demanding Seals

- What general maintenance practices can extend the lifespan of PTFE gaskets? Optimize Selection, Installation, and Monitoring

- What are the benefits of CNC machining for PTFE parts? Achieve Precision and Performance